Anti-blocking intelligent ammonia spraying device suitable for SCR denitration process and working method of anti-blocking intelligent ammonia spraying device

An intelligent and technological technology, applied in the chemical industry, can solve the problems of easy dust accumulation, increase the injection speed, and mutual interference of the ammonia flow field, and achieve the effect of fast injection speed, increase the injection speed, and solve the effect of easy dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

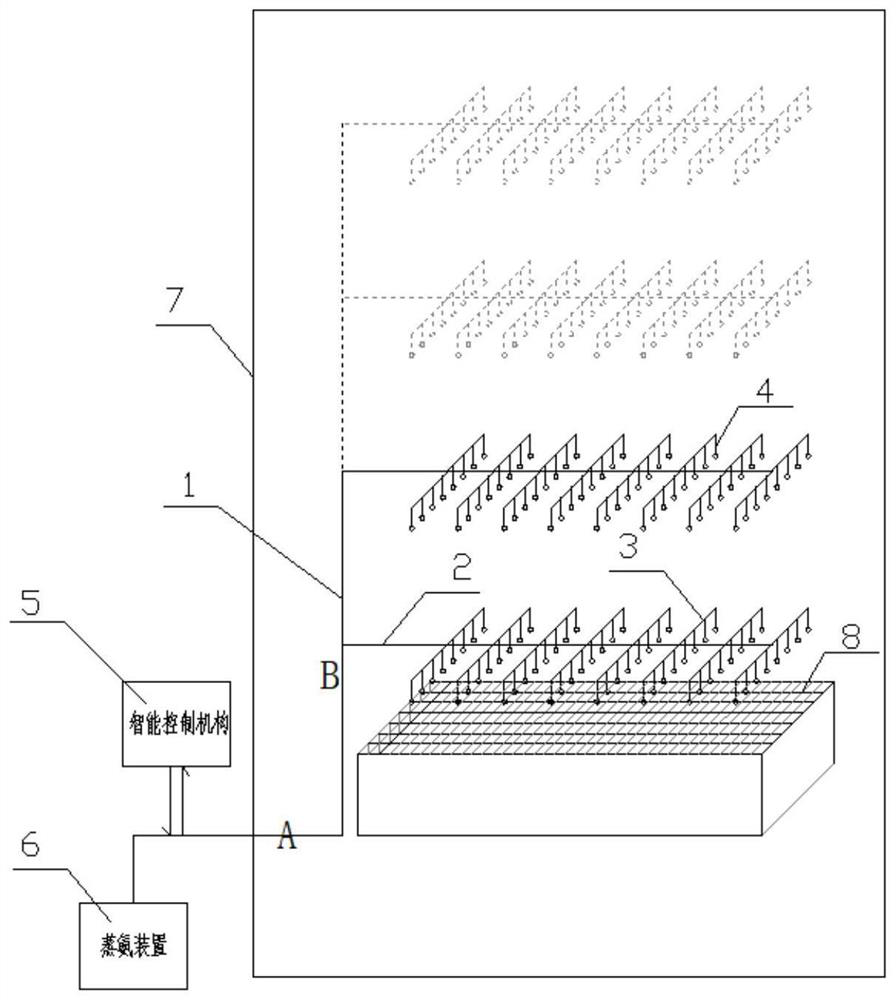

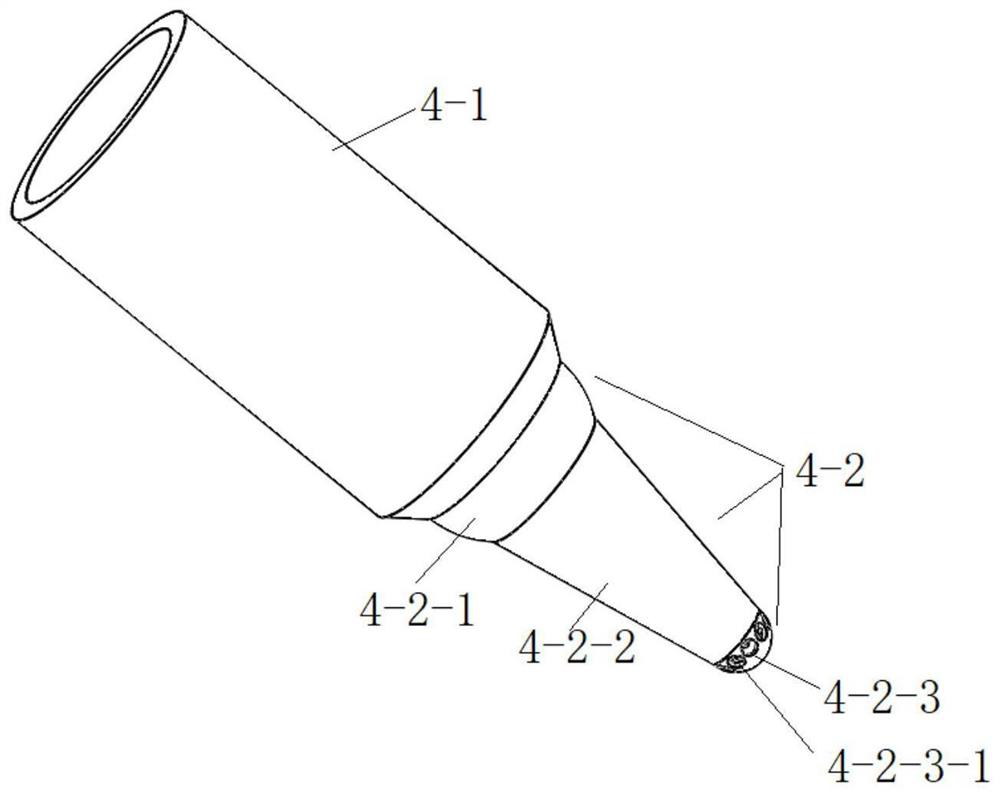

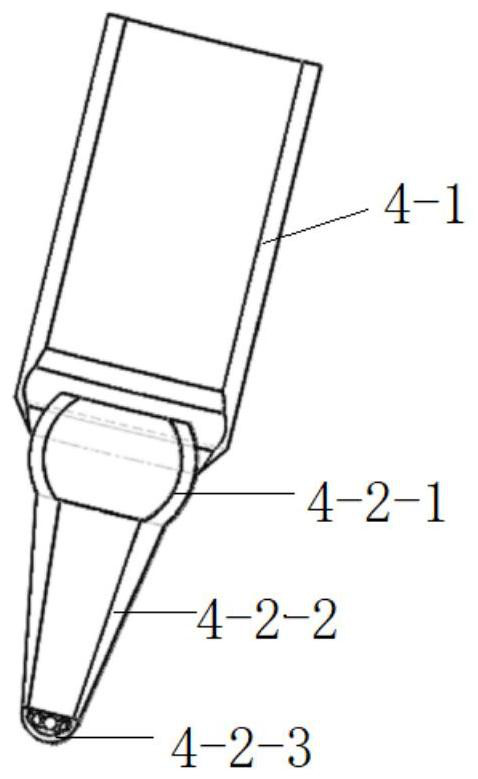

[0053] Such as Figure 1-Figure 3 As shown, an anti-blocking intelligent ammonia injection device suitable for SCR denitrification process includes an ammonia supply main pipe, an ammonia distribution main pipe, and an ammonia distribution branch pipe. It is characterized in that the ammonia supply main pipe includes an ammonia supply main pipe A and an ammonia supply main pipe B. The inlet of the ammonia supply main pipe A is connected to the outlet of the ammonia gas and air mixing pipe. The ammonia supply main pipe A extends through the side wall 7 of the flue to the inside of the flue and then connects with the ammonia supply main pipe B. The ammonia supply main pipe B runs along the flue gas The direction of movement is set. One end of multiple ammonia separation main pipes 2 is connected to ammonia supply main pipe B and is perpendicular to the axial direction of ammonia supply main pipe B. The other end of ammonia separation main pipe 2 is connected to multiple ammonia d...

Embodiment 2

[0067] An anti-blocking intelligent ammonia injection device suitable for SCR denitrification process, similar to Embodiment 1, the difference is that the ammonia separation main pipe 2 is arranged in the gap of the multi-layer catalyst layer 8 in two layers, and is connected to the B-axis of the ammonia supply main pipe connected vertically.

Embodiment 3

[0069] An anti-blocking intelligent ammonia injection device suitable for SCR denitrification process is similar to Embodiment 1, the difference is that multiple ammonia distribution branch pipes 3 connected to the same section of ammonia separation main pipe 2 can also be on different planes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com