Aluminum alloy thin-walled member and its high-efficiency hot stamping forming method and application

A technology of hot stamping and thin-walled components, which is applied in the direction of forming tools, vehicle parts, transportation and packaging, etc. It can solve the problems of inapplicability to industrial continuous production, thermal distortion process efficiency of parts, and low efficiency of heat treatment process, so as to shorten heat preservation The time required, the beat is stable and controllable, and the production process is continuous and safe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

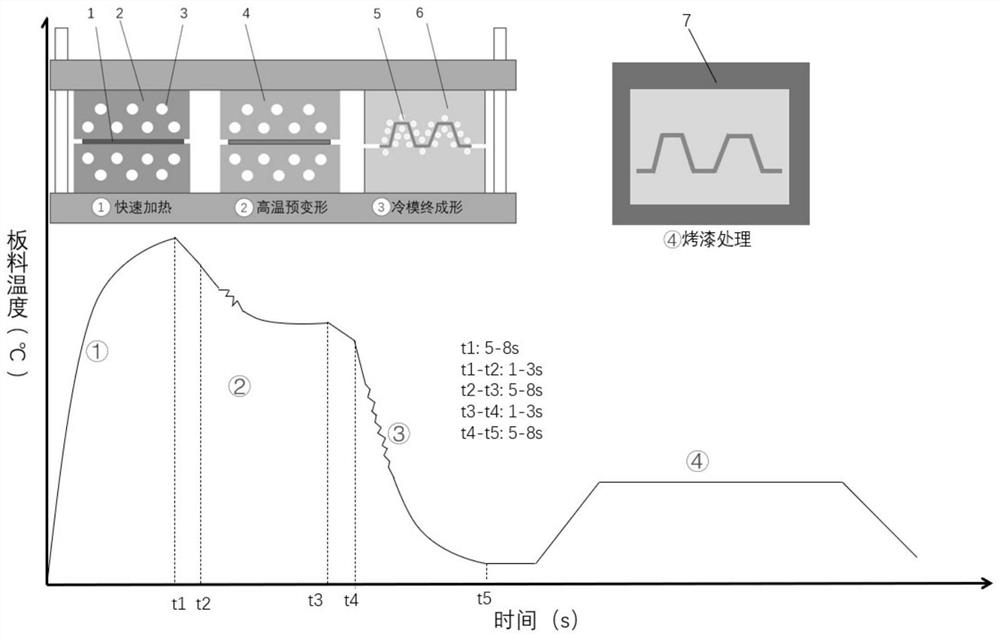

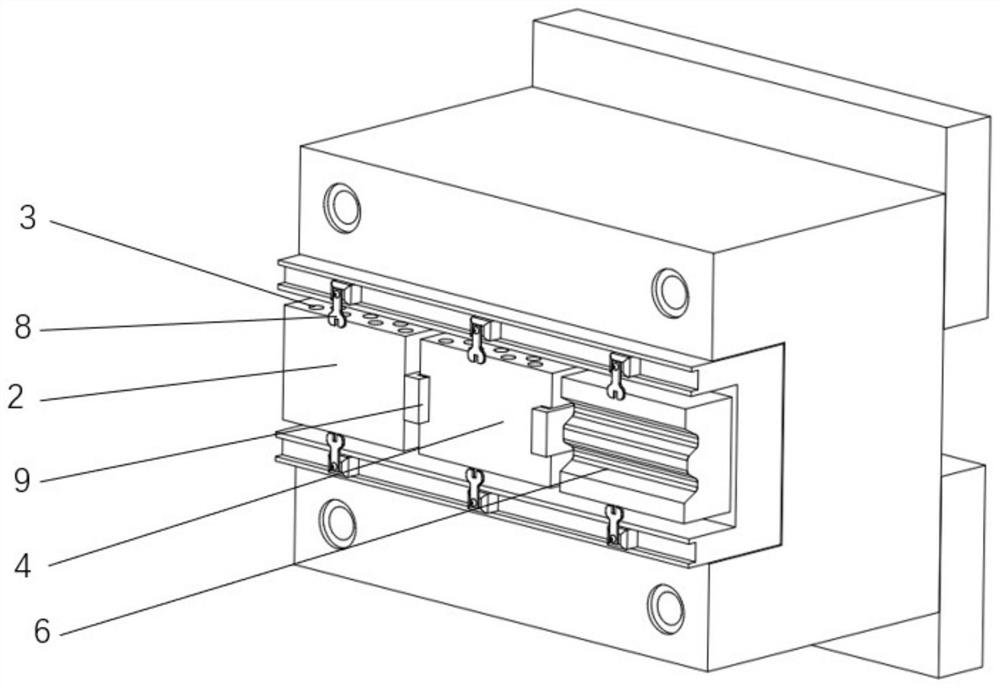

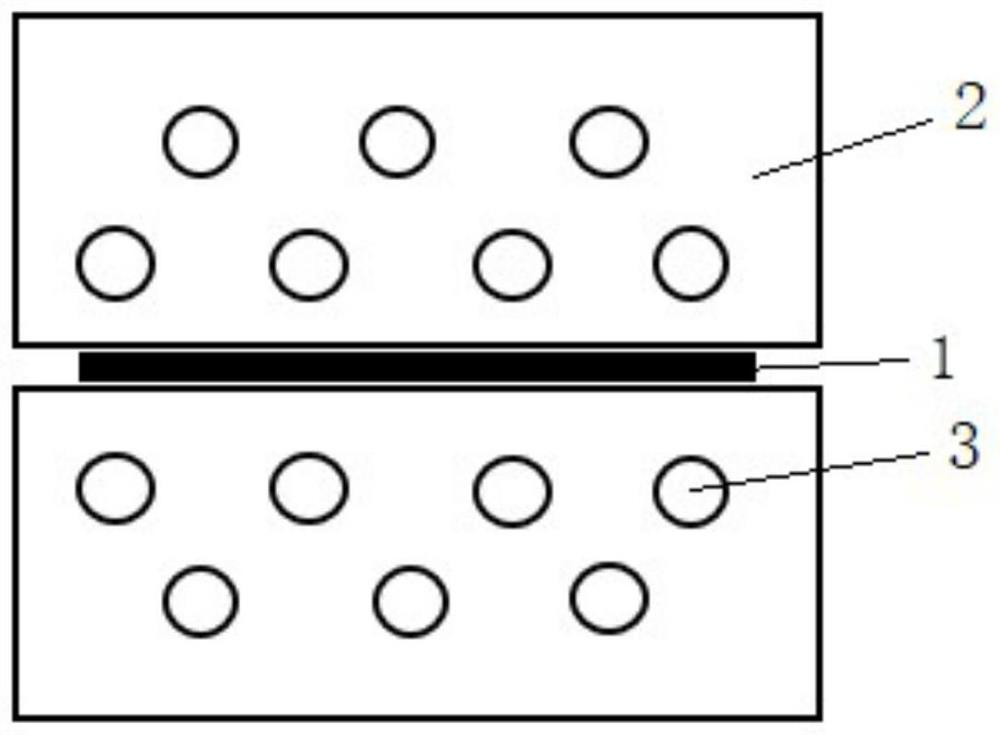

[0057] Such as image 3 , Figure 4 , Figure 5 , Figure 7 with Figure 8 As shown, this embodiment takes a 7075-T6 aluminum alloy custom pre-deformation as an example, and simulates the process route provided above, including rapid heating, pre-cooling + pre-deformation, cold mold final forming and baking paint treatment. Including the following steps:

[0058] (1) Rapid heating: The original 7075-T6 aluminum alloy plate 1 performs rapid heat exchange through contact with the high-temperature heated flat mold 2. The average heating rate is about 80°C / s after testing, and the heating temperature is higher than the solid solution temperature of the aluminum alloy. Lower than 250°C, hold the pressure in the flat mold 2 for 5s, and heat to the target temperature.

[0059] (2), pre-cooling + pre-deformation: transfer the high-temperature 7075-T6 aluminum alloy plate 1 to a high-temperature custom-made pre-deformation mold 4 at 400°C, the transfer time is 1s, and adopt a cust...

Embodiment 2

[0063] Such as image 3 , Figure 4 , Image 6 , Figure 7 with Figure 8 As shown, this embodiment takes a uniform pre-deformation of a 7075-T4 aluminum alloy as an example, and simulates the above-mentioned process route, including rapid heating, pre-cooling + pre-deformation, cold mold final forming and baking paint treatment. Including the following steps:

[0064] (1) Rapid heating: The original 7075-T4 aluminum alloy plate 1 performs rapid heat exchange by contacting the high-temperature heated flat mold 2. The average heating rate is about 80°C / s after testing, and the heating temperature is higher than the solid solution temperature of the aluminum alloy. Lower than 200°C, hold the pressure in the flat mold 2 for 5s, and heat to the target temperature.

[0065] (2), pre-cooling + pre-deformation: transfer the high-temperature 7075-T4 aluminum alloy plate 1 to the high-temperature pre-deformation mold 4 at 400°C, the transfer time is 1s, and the original 7075-T4 al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com