Aerated concrete and preparation method thereof

A technology for aerated concrete and rhombohedral soil is applied in the field of concrete, which can solve the problems of steam curing cracking, vertical cracking, horizontal cracking and the like, and achieves the effects of simple preparation method, convenient industrial production and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a kind of air-entrained concrete, its preparation method, comprises the following steps:

[0027] (1) Weigh 100kg of raw materials: 10kg of sand material, 20kg of fly ash, 20kg of cement, 15kg of mortar, 0.1kg of aluminum powder or aluminum powder paste, 6kg of quicklime, 0.5kg of gypsum, 5kg of stone powder, 8kg of straw charcoal, and 3kg of magnesite , and the balance is water. Among them, magnesite, as an autoclaved expansion regulator, is a product produced by calcination of magnesite at 1100°C, which can adjust the chemical expansion of the air-entrained concrete body to match the expansion coefficient of the steel bar, and eliminate the vertical expansion of the plate. crack. Index: fMgO (effective magnesia) > 80%, select heavy-burned magnesite with a digestion time of 4-6 hours, the reaction speed of magnesite is slow during the 3-hour period of static rest, and the reaction rate gradually accelerates after 3-4 hours, so that it can Max...

Embodiment 2

[0063] This embodiment provides a kind of air-entrained concrete, its preparation method, comprises the following steps:

[0064] (1) Weigh 100kg of raw materials: 20kg of sand material, 10kg of fly ash, 32kg of cement, 5kg of mortar, 2kg of aluminum powder or aluminum powder paste, 1kg of quicklime, 1.4kg of gypsum, 1kg of stone powder, 15kg of straw charcoal, and 0.5kg of magnesite , and the balance is water.

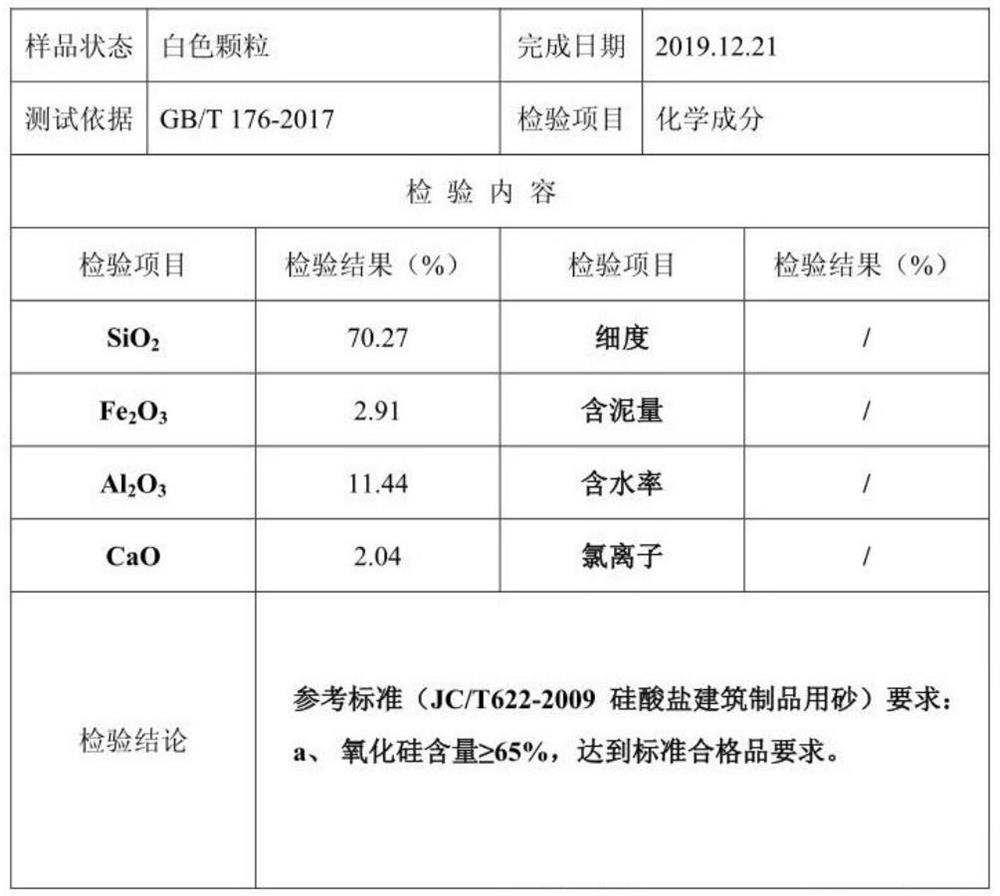

[0065] Among them, the sand material meets the requirements of the first-class product in the JC / T 622-2009 standard, and Jiangsha can be used.

[0066] As an autoclaved expansion regulator, magnesite is a product produced by calcination of magnesite at 1250°C. It can adjust the chemical expansion of the aerated concrete body to match the expansion coefficient of the steel bar and eliminate the vertical cracks of the plate. Index: fMgO (effective magnesia) > 80%, select heavy-burned magnesite with a digestion time of 4-6 hours, the reaction speed of magnesite is slow d...

Embodiment 3

[0071] This embodiment provides a kind of air-entrained concrete, its preparation method, comprises the following steps:

[0072] (1) Weigh 100kg of raw materials: sand material 10kg, fly ash 18kg, cement 24kg, mortar 12kg, aluminum powder or aluminum powder paste 0.5kg, quicklime 4kg, gypsum 0.5kg, stone powder 5kg, straw charcoal 8kg, magnesite 2kg , and the balance is water.

[0073] Among them, the sand material meets the requirements of first-class products in the JC / T 622-2009 standard, and quartz tailing sand can be used.

[0074] As an autoclaved expansion regulator, magnesite is a product produced by calcination of magnesite at 1150°C. It can adjust the chemical expansion of the aerated concrete body to match the expansion coefficient of the steel bar, and eliminate the vertical cracks of the plate. Index: fMgO (effective magnesia) > 80%, select heavy-burned magnesite with a digestion time of 4-6 hours, the reaction speed of magnesite is slow during the 3-hour period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com