High-entropy ceramic with high hardness and high conductivity as well as preparation method and application of high-entropy ceramic

A technology with high conductivity and high hardness, applied in the field of ceramic materials, can solve problems such as insufficient conductivity, and achieve the effects of low cost, wide application range and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

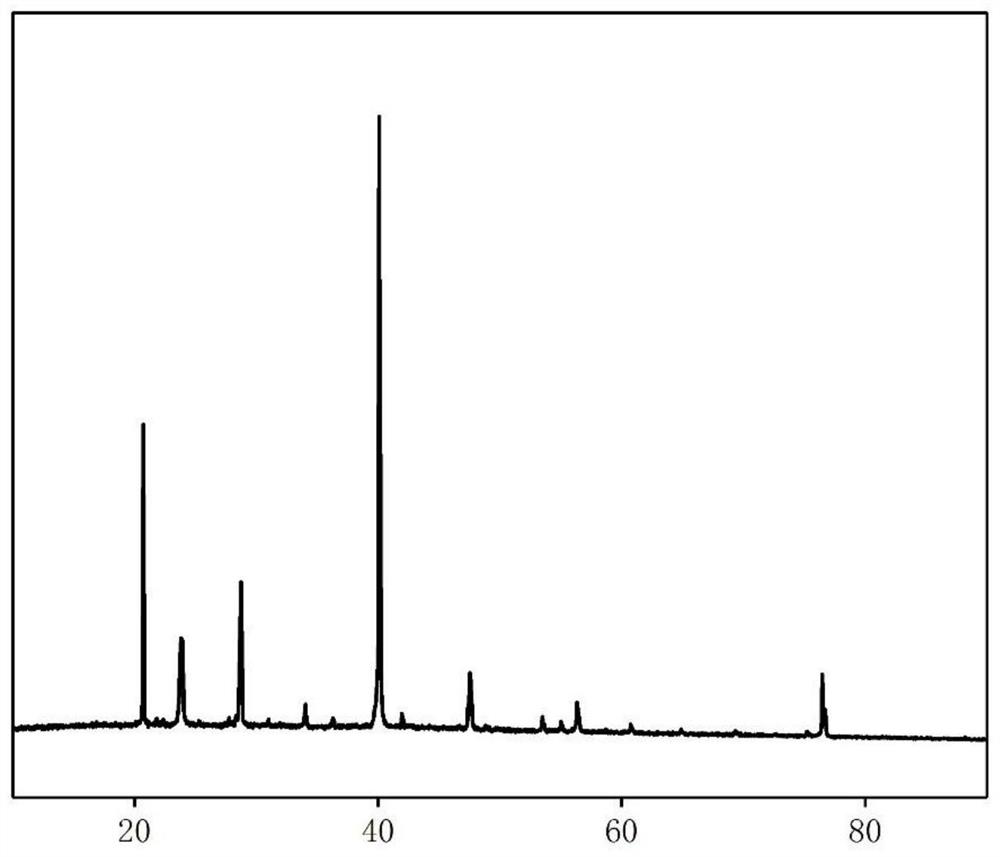

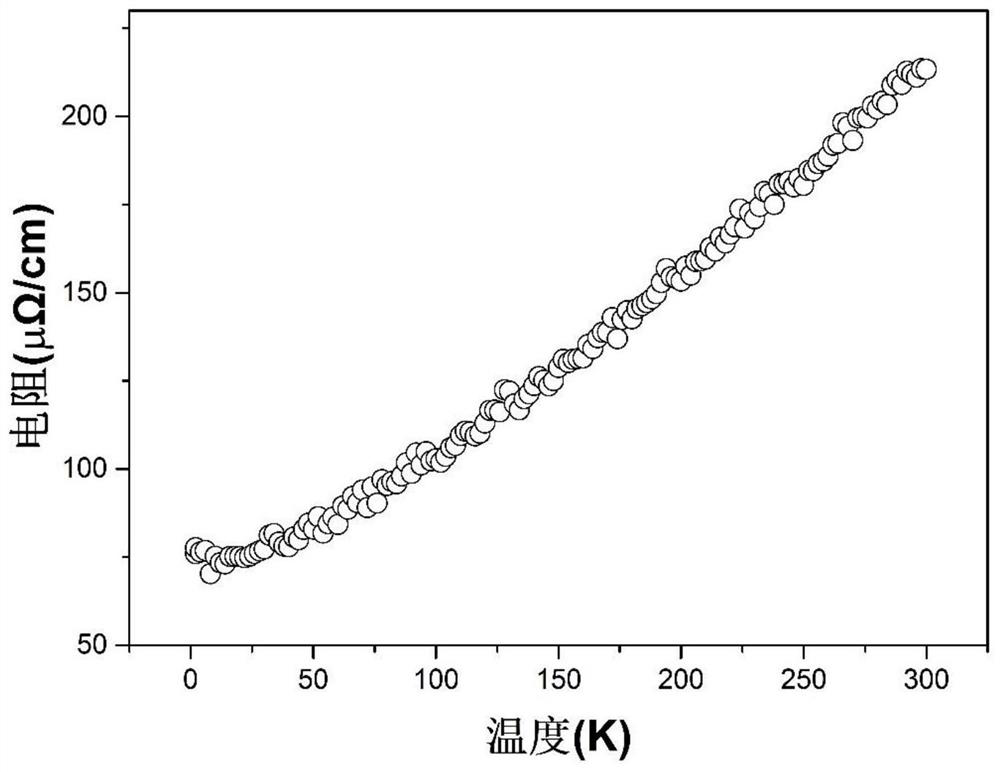

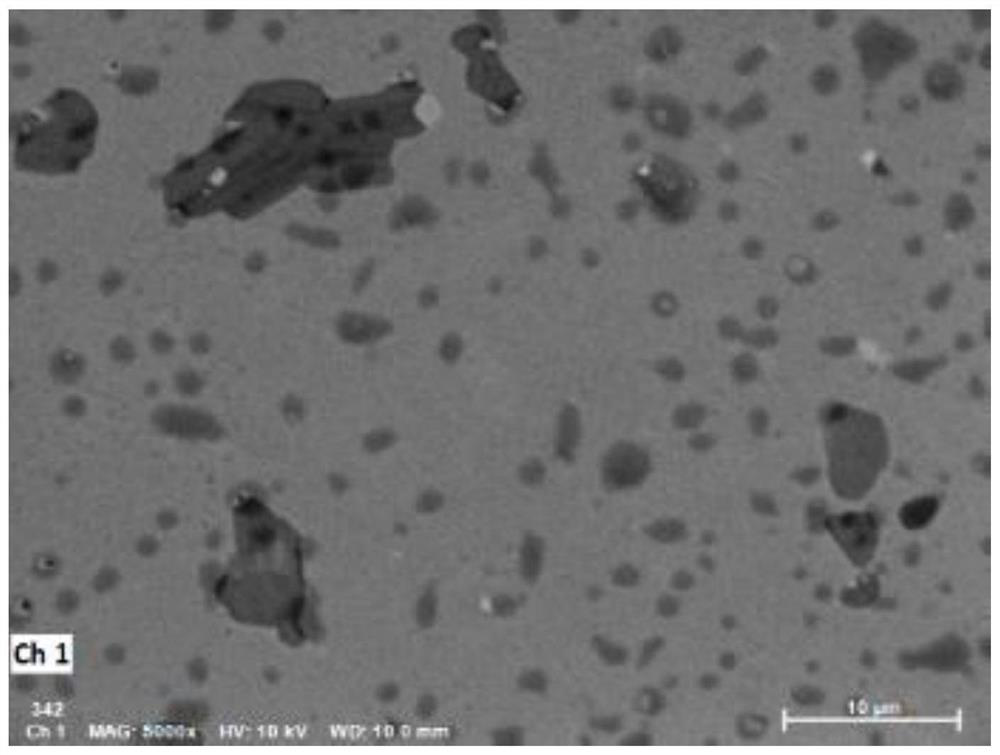

[0027] The preparation composition is (Dy, Ho, Er, Tm, Lu) B 12 According to the molar mass percentage of the high-entropy ceramics, Dy, Ho, Er, Tm, and Lu each account for 20%, and the balance is B and unavoidable impurities, and the impurity content is less than 0.05%. The preparation of high-entropy ceramics proceeds as follows:

[0028] (1) Dosing is carried out according to the molar mass of the high-entropy ceramic, and the amorphous boron powder is added according to the theoretically calculated 110%.

[0029] (2) the rare earth oxide (Dy 2 o 3 Powder, Ho 2 o 3 Powder, Er 2 o 3 Powder, Tm 2 o 3 Powder, Lu 2 o 3 powder) and the raw materials of amorphous boron powder are placed in the ball mill tank, and ZrO 2 The balls are grinding beads, which are mixed on a ball tank mill at a speed of 120 rpm for 24 hours to obtain a uniform mixed powder; the mass ratio of raw materials to ball milling beads is 1:0.2.

[0030] (3) Place the powder obtained in step (2) in ...

Embodiment 2

[0034] The preparation composition is (Dy, Ho, Er, Tm, Lu) B 12 The high-entropy ceramics, Dy, Ho, Er, Tm, and Lu each account for 20% according to the molar mass percentage, and the balance is B and unavoidable impurities, and the impurity content is less than 0.05. The preparation of high-entropy ceramics proceeds as follows:

[0035] (1) Dosing is carried out according to the molar mass of the high-entropy ceramic, and the amorphous boron powder is added according to the theoretically calculated 110%.

[0036] (2) the rare earth oxide (Dy 2 o 3 Powder, Ho 2 o 3 Powder, Er 2 o 3 Powder, Tm 2 o 3 Powder, Lu 2 o 3 powder) and the raw materials of amorphous boron powder are placed in the ball mill tank, and ZrO 2 The balls are grinding beads, which are mixed on a ball tank mill at a speed of 120 rpm for 24 hours to obtain a uniform mixed powder; the mass ratio of raw materials to ball milling beads is 1:0.2.

[0037] (3) Place the powder obtained in step (2) in a grap...

Embodiment 3

[0041] The preparation composition is (Dy, Ho, Er, Tm, Lu) B 12 The high-entropy ceramics, according to the molar mass percentage a=30%, b=30%, c=20%, d=10% and e=10%, the balance is B and unavoidable impurities, and the impurity content is less than 0.05. The preparation of high-entropy ceramics proceeds as follows:

[0042] (1) Dosing is carried out according to the molar mass of the high-entropy ceramic, and the amorphous boron powder is added according to the theoretically calculated 110%.

[0043] (2) Rare earth oxides (Dy 2 o 3 Powder, Ho 2 o 3 Powder, Er 2 o 3 Powder, Tm 2 o 3 Powder, Lu 2 o 3 powder) and the raw materials of amorphous boron powder are placed in the ball mill tank, and ZrO 2 The balls are grinding beads, which are mixed on a ball tank mill at a speed of 120 rpm for 24 hours to obtain a uniform mixed powder; the mass ratio of raw materials to ball milling beads is 1:0.2.

[0044] (3) Place the powder obtained in step (2) in a graphite mold, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com