2, 5-dichloronitrobenzene and micro-channel continuous synthesis process thereof

A technology of dichloronitrobenzene and a synthesis process, which is applied in the preparation of nitro compounds, organic chemistry, chemical/physical/physical chemical processes, etc., can solve the problems of long production cycle, high safety risk, low heat transfer efficiency and the like, Achieve the effect of short reaction time, reduced safety risk and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

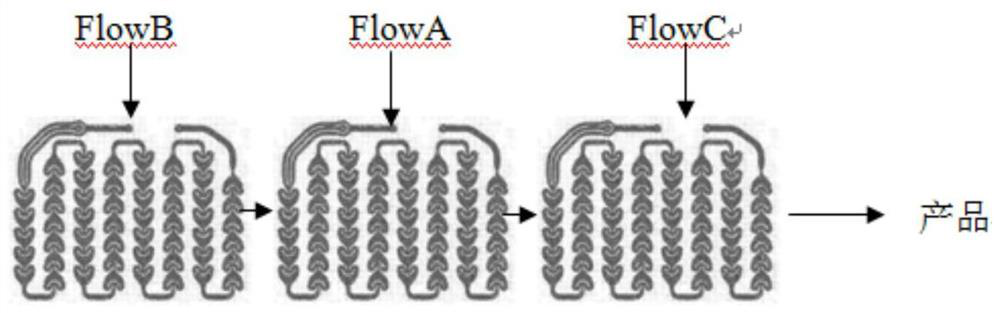

[0053] Embodiment 1 of the present invention provides a kind of microchannel continuous synthesis process of 2,5-dichloronitrobenzene, such as figure 1 As shown, the details are as follows:

[0054](1) Weigh 250g of raw material p-dichlorobenzene and heat it to a molten state as FlowA, measure 80mL of fuming nitric acid and 140mL of sulfuric acid to prepare a mixed acid as FlowB, and measure 150mL of sulfuric acid as FlowC;

[0055] (2) After the preheating microchannel reactor is completed, the flow rate of Control FlowA is 14mL / min to feed to reaction module one, the flow rate of Control FlowB is 17mL / min to feed in the preheating module, and the flow rate of Control Flow C is 11mL Feed material to reaction module two per minute, the reaction temperature zone one is 70°C, and the temperature zone two is 100°C for reaction. The molar ratio of p-dichlorobenzene to fuming nitric acid is 1:1.05, and the total amount of fuming nitric acid and sulfuric acid The mass ratio of the ...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a kind of microchannel continuous synthesis process of 2,5-dichloronitrobenzene, specifically as follows:

[0059] (1) Weigh 500g of raw material p-dichlorobenzene and heat it to a molten state as Flow A, measure 160mL of fuming nitric acid and 280mL of sulfuric acid to prepare a mixed acid as Flow B, and measure 300mL of sulfuric acid as Flow C;

[0060] (2) After the preheating microchannel reactor is completed, the flow rate of Control FlowA is 28mL / min to feed to reaction module one, the flow rate of Control FlowB is 34mL / min to feed in the preheating module, and the flow rate of Control Flow C is 19mL Feed material to reaction module two per minute, the reaction temperature zone one is 70°C, and the temperature zone two is 100°C for reaction. The molar ratio of p-dichlorobenzene to fuming nitric acid is 1:1.05, and the total amount of fuming nitric acid and sulfuric acid The mass ratio of the amount is 1:3.8, and the r...

Embodiment 3

[0063] Embodiment 3 of the present invention provides a kind of microchannel continuous synthesis technique of 2,5-dichloronitrobenzene, specifically as follows:

[0064] (1) Take by weighing 250g raw material p-dichlorobenzene and be heated to molten state as FlowA, measure the sulfuric acid that the fuming nitric acid of 80mL and the embodiment 1 of 140mL reclaim are mixed into mixed acid as Flow B, measure the reclaimed of embodiment 1 of 150mL Sulfuric acid as Flow C;

[0065] (2) After the preheating microchannel reactor is completed, the flow rate of Control FlowA is 14mL / min to feed to reaction module one, the flow rate of Control FlowB is 17mL / min to feed in the preheating module, and the flow rate of Control Flow C is 11mL Feed to the reaction module two per minute, the reaction temperature temperature zone one is 70°C, and the temperature zone two is 100°C for the reaction. The molar ratio of p-dichlorobenzene and fuming nitric acid is 1:1.05, and the fuming nitric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com