Preparation method and application of cross-linked hydrogel for muscle stem cell culture

A cross-linked hydrogel and stem cell culture technology, which is applied in the field of biological food materials, can solve the problems of poor mechanical properties and poor cell adhesion, achieve complete mechanical properties, improve biocompatibility, and facilitate adhesion of stem cells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

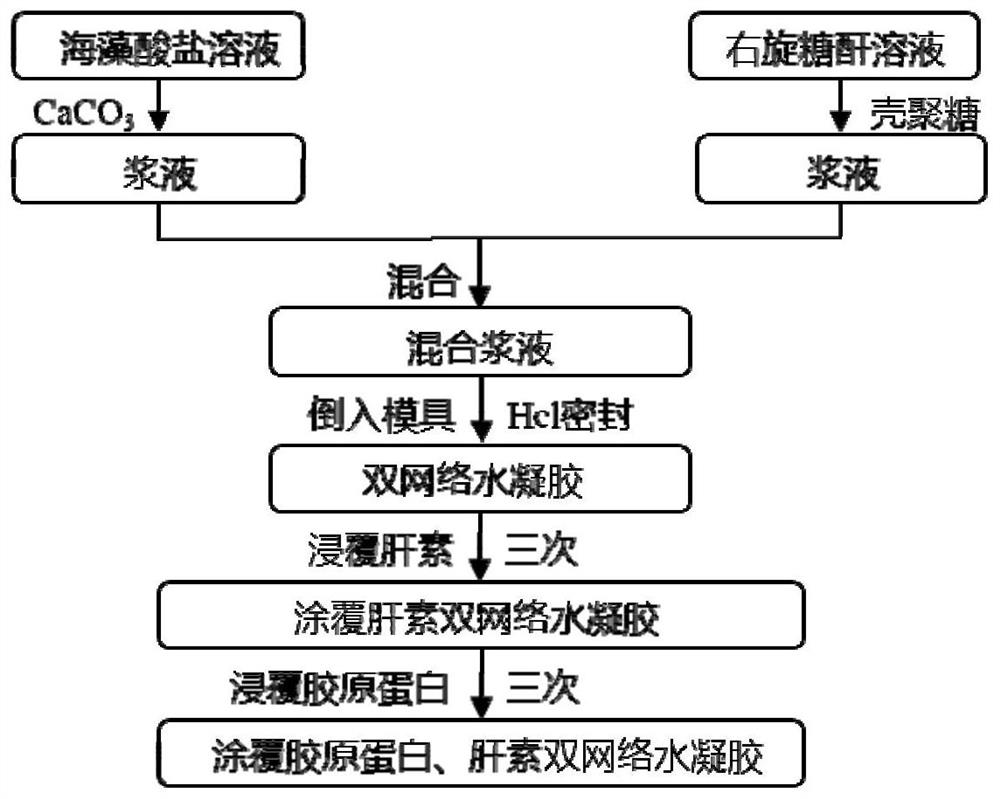

[0048] Embodiment 1: the preparation of chitosan / dextran / alginate / calcium ion double network cross-linked hydrogel

[0049] Add 1 g of sodium alginate (AR; 120 kDa; G / M ratio of 35 / 65) and 99 mL of deionized water to the beaker, and stir while adding until the sodium alginate dissolves to obtain a sodium alginate solution with a concentration of 1 wt%. Then add 0.1 g of calcium carbonate to the sodium alginate solution and stir until the calcium carbonate is uniformly dispersed to form a first gel material similar to mud. Then add 1 g of dextran (AR; 80-100 kDa) and 99 mL of deionized water to the beaker, stir until the dextran dissolves to obtain a 1 wt% dextran solution, add 2 g of chitosan (90.24% deacetylation; 230 kDa) into the dextran solution, and stir until the chitosan is evenly dispersed, forming a second gel mass similar to mud. Mix the two gel materials according to the ratio of the first gel material: the second gel material is 1:1, stir and mix evenly. The slur...

Embodiment 2

[0050] Example 2: Heparin-coated chitosan / dextran / alginate / calcium ion double network cross-linked hydrogel

[0051] Sodium heparin (0.5 g) and deionized water (100 mL) were added to the beaker to obtain a heparin solution (5.0 g / L). Prepared CS / Dex / Alg / Ca 2+ The hydrogel was soaked in PBS for 30 minutes, then soaked in heparin solution for 15 minutes, repeated three times, washed with PBS to remove unadsorbed heparin on the surface, and obtained CS / Dex / Alg / Ca coated with heparin by electrostatic adsorption. 2+ Hydrogels.

Embodiment 3

[0052] Example 3: Collagen coated chitosan / dextran / alginate / calcium ion double network cross-linked hydrogel

[0053] Collagen and deionized water were added to a beaker to obtain a collagen solution (20 wt%). The prepared CS / Dex / Alg / Ca coated with heparin 2+ The hydrogel was soaked in PBS for 30 minutes, then soaked in collagen solution for 15 minutes, repeated three times, washed with PBS to remove the collagen on the surface, through the interaction between collagen and heparin, a gel coated with collagen and heparin was obtained. CS / Dex / Alg / Ca 2+ Hydrogels. Subsequently, the hydrogel was freeze-dried in a vacuum freeze dryer (-80 °C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com