Ether-bond-free anion exchange membrane of polyaryl piperidine for fuel cell and preparation method of ether-bond-free anion exchange membrane

An anion-exchange membrane and polyarylpiperidine technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems that limit the promotion and development of proton-exchange membrane fuel cells, and achieve the balance of alkali resistance and conductivity, Improve alkaline stability and improve alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

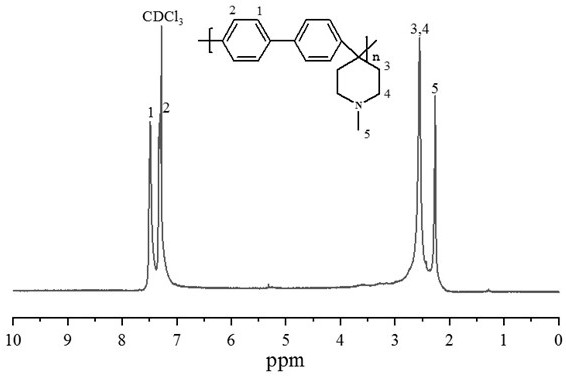

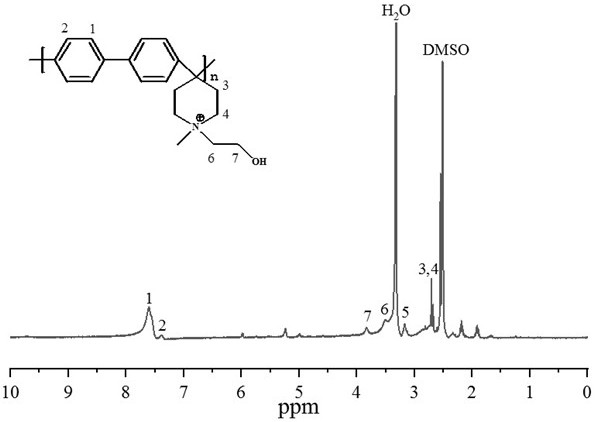

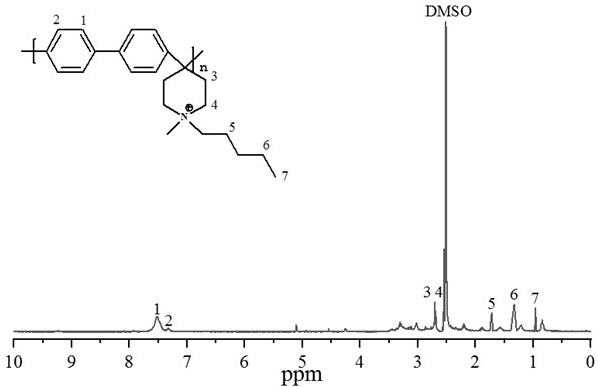

[0023] Embodiment one, by Figure 1-3 Given, the present invention provides the anion-exchange membrane without ether bond of polyarylpiperidine for fuel cell, and this anion-exchange membrane is prepared according to the different molar ratios of grafted brominated n-butane and bromoethanol:

[0024] Wherein the molar ratio of grafted n-butane bromide to bromoethanol is: a:b, where a and b are even numbers of 2 to 8 and a+b=10;

[0025] Described, structural formula is as shown in formula I:

[0026] .

[0027] Example, by Figure 1-3 Given, the invention provides the preparation method of the polyarylpiperidine-free anion-exchange membrane of polyarylpiperidine for fuel cells, comprising the steps of:

[0028] Step 1: Add 0.02mol (3.084g) biphenyl, 0.024mol (2.715g) N-methyl-4-piperidone, and 6mL dichloromethane to a 100mL three-neck flask connected with mechanical stirring under ice-water bath conditions, and dissolve After mixing evenly, add 0.75mL trifluoroacetic ac...

Embodiment 2

[0032] Embodiment two, by Figure 1-3 Given, the present invention provides the anion-exchange membrane without ether bond of polyarylpiperidine for fuel cell, and this anion-exchange membrane is prepared according to the different molar ratios of grafted brominated n-butane and bromoethanol:

[0033] Wherein the molar ratio of grafted n-butane bromide to bromoethanol is: a:b, where a and b are even numbers of 2 to 8 and a+b=10;

[0034] Described, structural formula is as shown in formula I:

[0035] .

[0036] Example, by Figure 1-3 Given, the invention provides the preparation method of the polyarylpiperidine-free anion-exchange membrane of polyarylpiperidine for fuel cells, comprising the steps of:

[0037] Step 1: Add 0.02mol (3.084g) biphenyl, 0.024mol (2.715g) N-methyl-4-piperidone, 6mL dichloromethane to a 100mL three-necked flask connected with mechanical stirring under ice-water bath conditions, After dissolving and mixing evenly, add 0.063mol (0.75ml) trifluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com