Environmentally-friendly epoxy modified acrylic coating for hardware parts, and preparation method thereof

An epoxy-modified, environmentally friendly coating technology, applied in anti-corrosion coatings, fire-resistant coatings, conductive coatings, etc., can solve the problems of poor water resistance, alkali resistance and weather resistance, easy to be corroded, and become brittle, and achieve a large specific surface area , Good UV shielding performance, high chemical activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

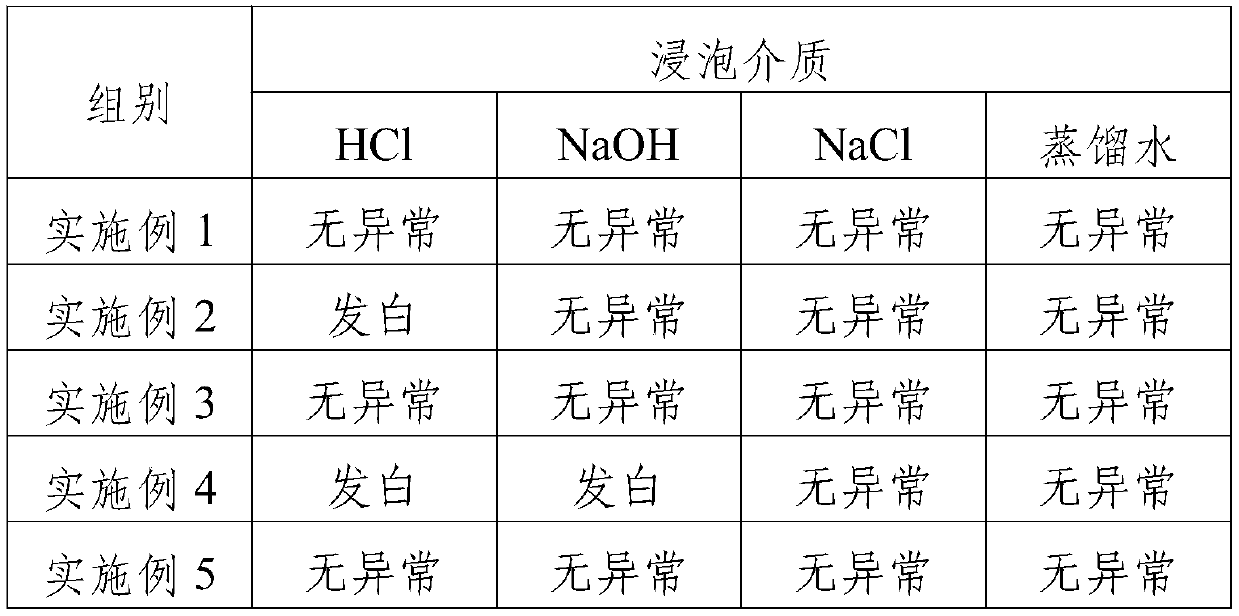

Examples

Embodiment 1

[0042] An environmentally friendly coating for epoxy-modified acrylic hardware parts, comprising the following raw materials in parts by weight: 75 parts of epoxy-modified acrylic resin, 0.8 part of sodium methylene bis-naphthalene sulfonate, 0.5 part of propylene glycol phenyl ether, hydroxypropyl methyl 1.2 parts of cellulose, 1.6 parts of dimethylethanolamine, 4.5 parts of barium sulfate, 2.4 parts of calcium oxide, 1.5 parts of nano zinc oxide, 1.4 parts of graphene oxide, 12 parts of water; epoxy modified acrylic resin is made of epoxy resin E- 44. Butyl acrylate, methacrylic acid, and styrene are prepared by ring-opening esterification. The weight parts of each raw material of epoxy-modified acrylic resin are: epoxy resin E-4418 parts, butyl acrylate 18 parts, methacrylic acid 15 parts, 20 parts of styrene, 5 parts of octylphenol polyoxyethylene ether, 2.5 parts of sodium dodecyl sulfate, 0.8 parts of ammonium persulfate, and 0.3 parts of sodium bicarbonate.

[0043] A p...

Embodiment 2

[0050] An epoxy-modified acrylic acid environmental protection coating for hardware parts, comprising the following raw materials in parts by weight: 60 parts of epoxy-modified acrylic resin, 0.6 part of sodium methylene bis-naphthalene sulfonate, 1 part of propylene glycol phenyl ether, hydroxypropyl methyl 1.5 parts of cellulose, 2 parts of dimethylethanolamine, 3.5 parts of barium sulfate, 2.2 parts of calcium oxide, 0.6 parts of nano-zinc oxide, 0.8 parts of graphene oxide, 15 parts of water; epoxy modified acrylic resin is composed of epoxy resin E- 51. Butyl acrylate, methacrylic acid, and styrene are prepared by ring-opening esterification. The parts by weight of the raw materials of epoxy-modified acrylic resin are: epoxy resin E-5120 parts, butyl acrylate 10 parts, methacrylic acid 15 parts, 25 parts of styrene, 6 parts of octylphenol polyoxyethylene ether, 2 parts of sodium dodecyl sulfate, 1.5 parts of potassium persulfate, and 0.5 parts of sodium bicarbonate.

[00...

Embodiment 3

[0058] An epoxy-modified acrylic acid environmental protection coating for hardware parts, comprising the following raw materials in parts by weight: 75 parts of epoxy-modified acrylic resin, 0.5 part of sodium methylene bis-naphthalene sulfonate, 0.8 part of propylene glycol phenyl ether, hydroxypropyl methyl 1.5 parts of cellulose, 2 parts of dimethylethanolamine, 5 parts of barium sulfate, 2.5 parts of calcium oxide, 1.8 parts of nano-zinc oxide, 2 parts of graphene oxide, 12 parts of water; epoxy modified acrylic resin is made of epoxy resin E- 44. Butyl acrylate, methacrylic acid, and styrene are prepared by ring-opening esterification. The parts by weight of each raw material of epoxy-modified acrylic resin are: epoxy resin E-4415 parts, butyl acrylate 15 parts, methacrylic acid 10 parts, 20 parts of styrene, 6 parts of octylphenol polyoxyethylene ether, 3 parts of sodium dodecylsulfonate, 1.2 parts of ammonium persulfate, and 0.2 parts of sodium bicarbonate.

[0059] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com