High-thermal-conductivity antibacterial composite material and preparation method thereof

A composite material, high thermal conductivity technology, applied in the field of composite materials, to achieve the effect of increasing specific surface area, good photochemical effect, and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

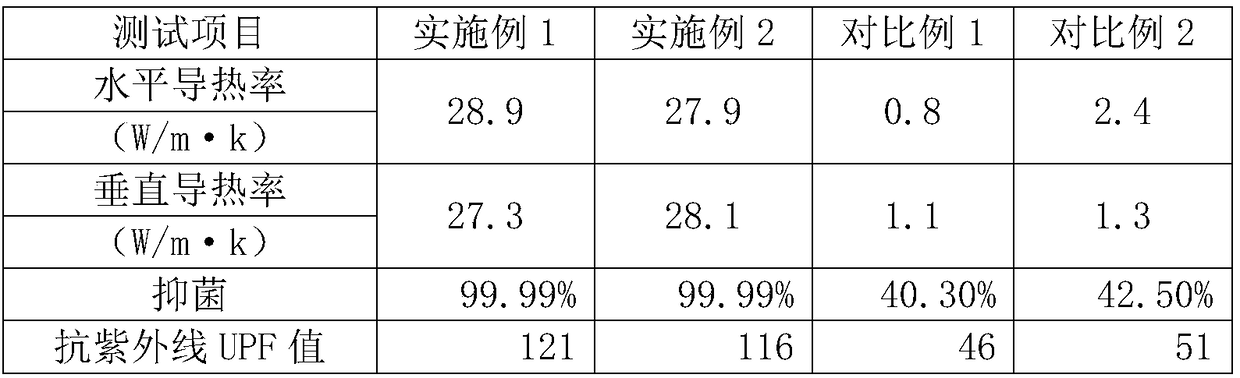

Examples

Embodiment 1

[0030] A preparation method of a high thermal conductivity antibacterial composite material, comprising the following steps:

[0031] 1) The polyacrylonitrile-based carbon fiber is subjected to corona treatment: the corona treatment is carried out under the condition of a mixed gas of oxygen and nitrogen, the volume ratio of oxygen and nitrogen is 2:8, and the treatment is performed at 8kV for 5s.

[0032] 2) Mix thermosetting epoxy resin, silicone leveling agent, diaminodiphenylmethane, ethylene glycol and deionized water, stir and mix at 800r / min for 20min, then add orientation agent, stir and mix at 800r / min for 25min , then add silver nanowires, and stir and mix for 30 minutes under the condition of 800r / min, to obtain the epoxy resin modifier. The directional agent is selected from BYK, the model is Aquatix 8421; the size of the silver nanowire is 20-50nm; the length is 1000-1800nm. The epoxy resin, silicone leveling agent, diaminodiphenylmethane, ethylene glycol, deioni...

Embodiment 2

[0035] A preparation method of a high thermal conductivity antibacterial composite material, comprising the following steps:

[0036] 1) The polyacrylonitrile-based carbon fiber is subjected to corona treatment: the corona treatment is carried out under the condition of a mixed gas of oxygen and nitrogen, the volume ratio of oxygen and nitrogen is 2:8, and the treatment is performed at 7kV for 7s.

[0037] 2) Mix thermosetting epoxy resin, silicone leveling agent, diaminodiphenylmethane, ethylene glycol and deionized water, stir and mix at 600r / min for 25min, then add orientation agent, stir and mix at 800r / min for 20min , then add silver nanowires, and stir and mix for 30 minutes under the condition of 800r / min, to obtain the epoxy resin modifier. The directional agent is selected from BYK, the model is Aquatix 8421; the size of the silver nanowire is 20-50nm; the length is 1000-1800nm. The mass ratio of the epoxy resin, silicone leveling agent, diaminodiphenylmethane, ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com