PBT material and preparation method thereof

A technology of nano-zinc oxide and glass fiber, applied in the field of polyester, to achieve high heat resistance, poor hydrolysis resistance, and optimized process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

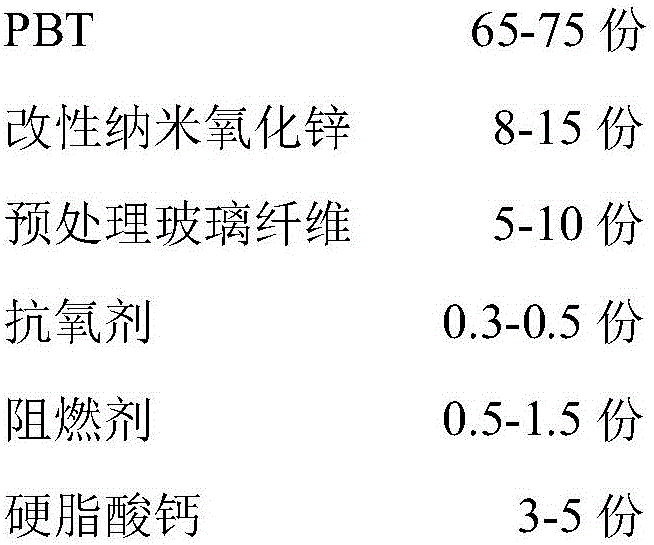

Image

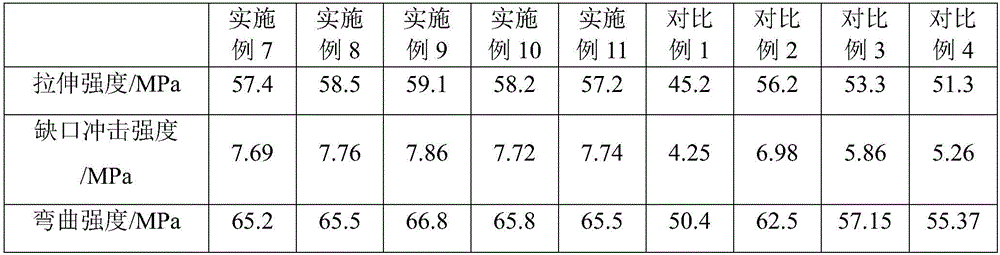

Examples

Embodiment 1

[0037] Step 1: Add nano-zinc dioxide, coupling agent isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and toluene, stir and heat to reflux for 2 hours, centrifuge, wash with acetone, bake at 120°C for 2 hours, Wherein the weight ratio of nano zinc oxide and coupling agent is 1: 0.3, the mass volume ratio of nano zinc oxide and toluene is 1: 10g / mL;

[0038] Step 2: Add the dried nano-zinc oxide, terephthalic acid, and 1,4-butanediol in sequence, heat to melt, add the catalyst butyl titanate, stir, and heat up until water evaporates , constant temperature reaction for 30min, the vacuum degree was evacuated to 2000Pa, and the reaction was continued for 1h. Wherein the weight ratio of nano zinc oxide and terephthalic acid is 1:4, and the molar ratio of terephthalic acid, 1,4-butanediol and butyl titanate is 1:1.2:0.01;

[0039] Step 3: Add solvent phenol to the reactant, vibrate ultrasonically until the reactant is completely dissolved, then perform centrifugation, wash on...

Embodiment 2

[0041] Step 1: Add nano-zinc dioxide, coupling agent isopropyl tris(dioctyl phosphate acyloxy) titanate and toluene, stir and heat to reflux for 2 hours, centrifuge, wash with acetone, and bake at 120°C for 2 hours, wherein The weight ratio of nano zinc oxide and coupling agent is 1: 0.3, and the mass volume ratio of nano zinc oxide and toluene is 1: 10g / mL;

[0042] Step 2: Add the dried nano-zinc oxide, terephthalic acid, and 1,4-butanediol in sequence, heat to melt, add the catalyst butyl titanate, stir, and heat up until water evaporates , constant temperature reaction for 30min, the vacuum degree was evacuated to 2000Pa, and the reaction was continued for 1h. Wherein the weight ratio of nano zinc oxide and terephthalic acid is 1:6, and the molar ratio of terephthalic acid, 1,4-butanediol and butyl titanate is 1:1.3:0.02;

[0043]Step 3: Add solvent phenol to the reactant, vibrate ultrasonically until the reactant is completely dissolved, then perform centrifugation, wash...

Embodiment 3

[0045] Step 1: Add nano-zinc dioxide, coupling agent isopropyl dioleate acyloxy (dioctyl phosphate acyloxy) titanate and toluene, stir and heat to reflux for 2h, centrifuge, wash with acetone, at 120°C Bake for 2 hours, wherein the weight ratio of nano-zinc oxide to coupling agent is 1:0.3, and the mass-volume ratio of nano-zinc oxide to toluene is 1:10g / mL;

[0046] Step 2: Add the dried nano-zinc oxide, terephthalic acid, and 1,4-butanediol in sequence, heat to melt, add the catalyst butyl titanate, stir, and heat up until water evaporates , constant temperature reaction for 30min, the vacuum degree was evacuated to 2000Pa, and the reaction was continued for 1h. Wherein the weight ratio of nano zinc oxide and terephthalic acid is 1:8, and the molar ratio of terephthalic acid, 1,4-butanediol and butyl titanate is 1:1.5:0.03;

[0047] Step 3: Add solvent phenol to the reactant, vibrate ultrasonically until the reactant is completely dissolved, then perform centrifugation, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com