Machining and forming process for corrosion-resistant screw for ship

A processing molding and corrosion-resistant technology, applied to nuts, bolts, applications, etc., can solve the problems of weakened corrosion resistance and waste of resources, and achieve the effects of improving weather resistance, reducing defective rate, and high chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

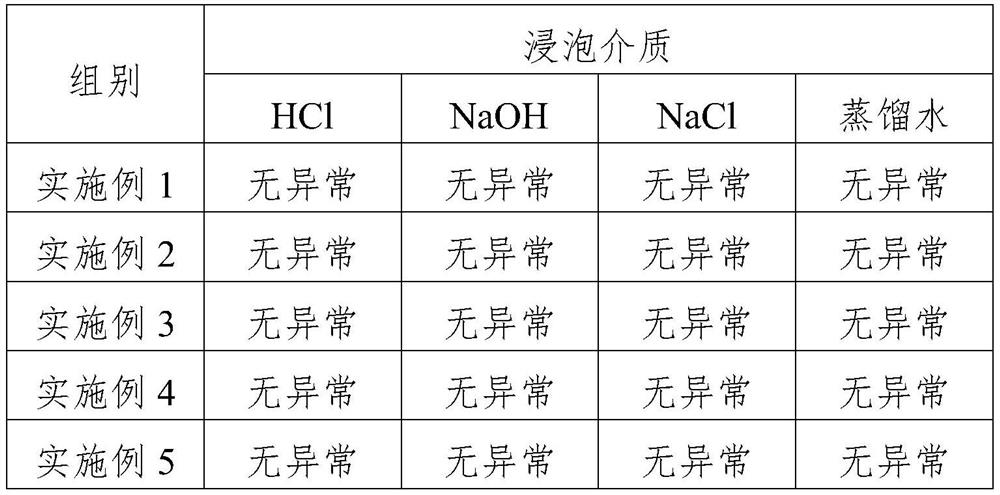

Examples

Embodiment 1

[0027] A process for processing and forming corrosion-resistant screws used in ships, specifically comprising the following steps:

[0028] (1) Put the CH38F wire rod into the hanging furnace, slowly raise the temperature for 3.5h to 740°C, keep it for 5h, and then cool down to room temperature with the furnace to obtain the pretreated CH38F wire rod;

[0029] (2) Immerse the pretreated CH38F wire rod in hydrochloric acid with a mass concentration of 15% for 20 minutes, take it out and wash it with water;

[0030] (3) Putting the wire rod processed through step (2) into a cold heading machine to form it, so as to obtain the head and the bar of the screw;

[0031] (4) Utilize the thread rolling machine to rub out the thread on the rod of the screw, and repeatedly rub the thread 2 times to obtain the pre-treated screw;

[0032] (5) Heat the pre-treated screw to 650°C, keep it warm for 2 hours, cool to room temperature, then heat to 500°C and temper for 20 minutes, and after coo...

Embodiment 2

[0037] A process for processing and forming corrosion-resistant screws used in ships, specifically comprising the following steps:

[0038] (1) Put the CH38F wire rod into the hanging furnace, slowly raise the temperature for 3.5h to 740°C, keep it for 5h, and then cool down to room temperature with the furnace to obtain the pretreated CH38F wire rod;

[0039] (2) Immerse the pretreated CH38F wire rod in hydrochloric acid with a mass concentration of 15% for 20 minutes, take it out and wash it with water;

[0040] (3) Putting the wire rod processed through step (2) into a cold heading machine to form it, so as to obtain the head and the bar of the screw;

[0041] (4) Utilize the thread rolling machine to rub out the thread on the rod of the screw, and repeatedly rub the thread 2 times to obtain the pre-treated screw;

[0042] (5) Heat the pre-treated screw to 660°C, keep it warm for 2.2h, cool to room temperature, then heat to 550°C and temper for 20min, after cooling to room...

Embodiment 3

[0047] A process for processing and forming corrosion-resistant screws used in ships, specifically comprising the following steps:

[0048] (1) Put the CH38F wire rod into the hanging furnace, slowly raise the temperature for 3.8h to 750°C, keep it warm for 5.5h, and then cool down to room temperature with the furnace to obtain the pretreated CH38F wire rod;

[0049] (2) Immerse the pretreated CH38F wire rod in hydrochloric acid with a mass concentration of 16% for 22 minutes, take it out and wash it with water;

[0050] (3) Putting the wire rod processed through step (2) into a cold heading machine to form it, so as to obtain the head and the bar of the screw;

[0051] (4) Utilize a thread rolling machine to rub out the thread on the rod of the screw, and repeatedly rub the thread 3 times to obtain the pre-treated screw;

[0052] (5) Heat the pre-treated screw to 680°C, keep it warm for 2.5h, cool to room temperature and then heat to 550°C and temper for 25min, after cooling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com