A kind of near-infrared luminescent material and preparation method thereof, and near-infrared LED

A luminescent material and near-infrared technology, applied in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of lack of near-infrared phosphors, etc., and achieve the effect of increased luminous intensity and excellent luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of the near-infrared luminescent material described in the above technical scheme, comprising the following steps:

[0055] A) Mix the compound containing A element, the compound containing Q element, the compound containing L element, the compound containing M element and the chromium source compound to obtain a mixture;

[0056] B) The mixture is sintered to obtain a luminescent material.

[0057] Regarding step A):

[0058] In the present invention, the compound containing element A is preferably one or more of oxides, phosphates, oxalates and nitrates of element A. In some embodiments of the present invention, the compound containing element A is yttrium oxide.

[0059] In the present invention, the compound containing Q element is preferably one or more of oxides, hydroxides, acetates, carbonates, phosphates and nitrates of Q elements. In some embodiments of the present invention, the compound containing Q...

Embodiment 1

[0072] The raw materials are yttrium oxide (99.95%), barium carbonate (99.99%), aluminum oxide (99.99%), germanium oxide (99.999%), chromium oxide (analytical pure), and the molar ratio between them is 2.8:0.2:4.75: 0.2: 0.05, add 1% of H when mixing 3 BO 3 (99.99%) fully ground to obtain a mixture. Put it in a corundum crucible, pre-fire at 1000°C for 4 hours, cool to room temperature and grind again, and finally sinter at 1450°C for 4 hours, naturally cool and take out the sample, which is the product.

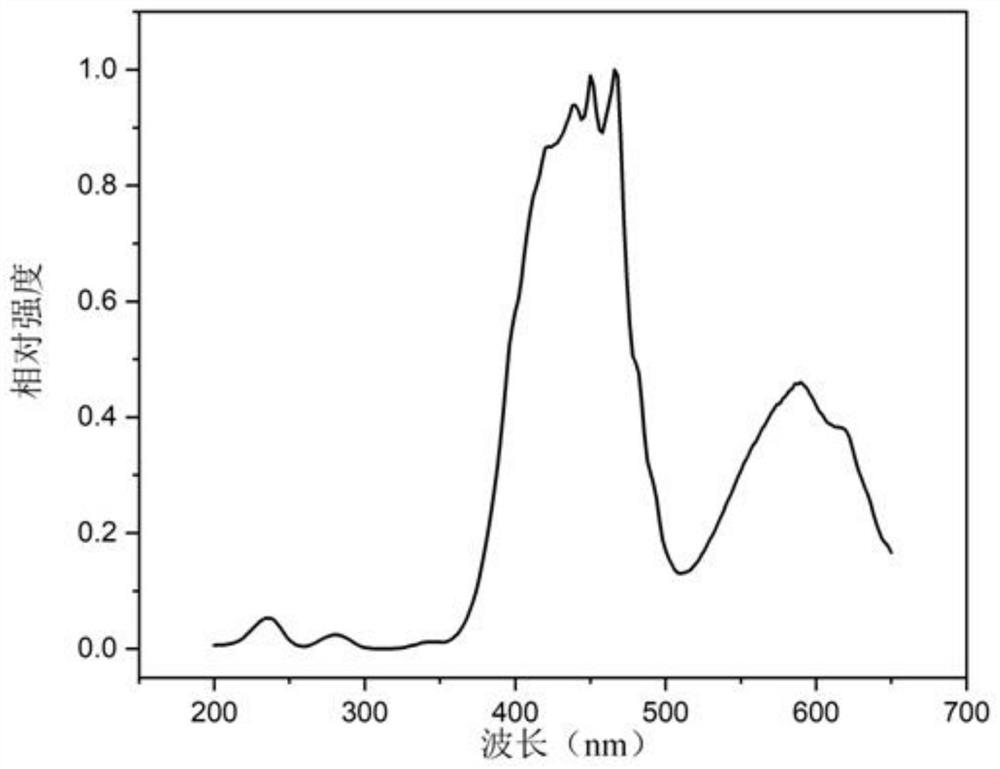

[0073] The obtained sample is light green powder, and its excitation spectrum is broadband, such as figure 1 shown, figure 1 It is the excitation spectrum of the near-infrared luminescent material obtained in Example 1, and the monitoring peak position is 710 nm.

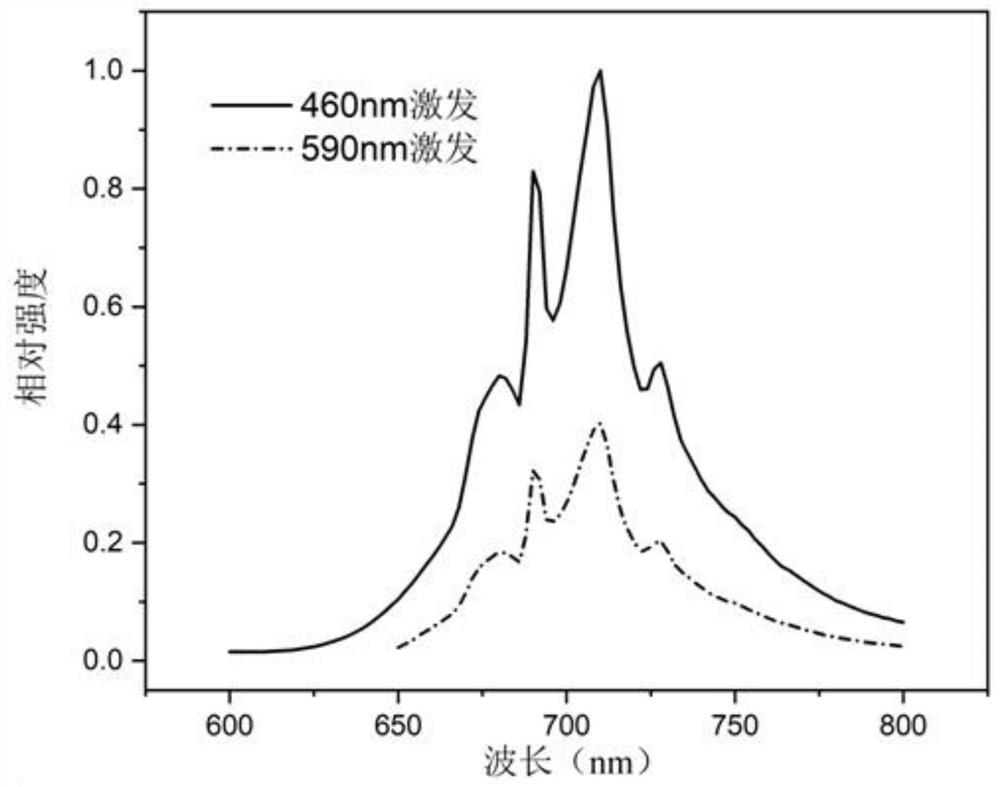

[0074] The emission spectrum of the obtained sample was tested and the results were as follows figure 2 shown, figure 2 It is the emission spectrum of the near-infrared light-emitting material obtained in ...

Embodiment 2

[0078]The raw materials are yttrium oxide (99.95%), barium carbonate (99.99%), aluminum oxide (99.99%), germanium oxide (99.999%), chromium oxide (analytical pure), and the molar ratio between them is 2.6:0.4:4.55: 0.4:0.05, add 1% H when mixing 3 BO 3 (99.99%) is fully ground and uniform, placed in a corundum crucible, pre-fired at 1000 ° C for 4 hours, cooled to room temperature and ground again, and finally sintered at 1450 ° C for 4 hours, naturally cooled to take out the sample, which is the product. The obtained sample is light green powder with molecular formula Y 2.6 Ba 0.4 Al 4.55 Ge 0.4 O 12 : 0.05Cr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com