Novel crosshead type two-stroke uniflow scavenging piston assembly

A crosshead type and piston assembly technology, which is applied to pistons, internal combustion piston engines, engine components, etc., can solve the problems of poor ventilation quality, hindering the smooth discharge of exhaust gas, and affecting the quality of exhaust gas, so as to avoid the chilling effect of the chamber wall , Improve combustion efficiency, improve the effect of ventilation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined arbitrarily with each other.

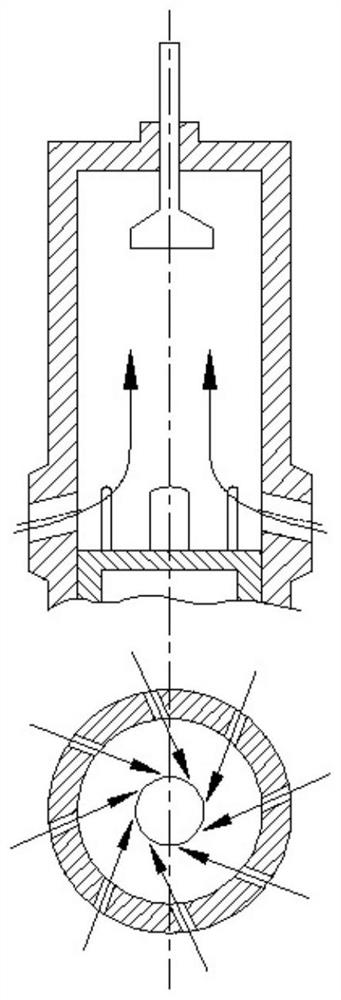

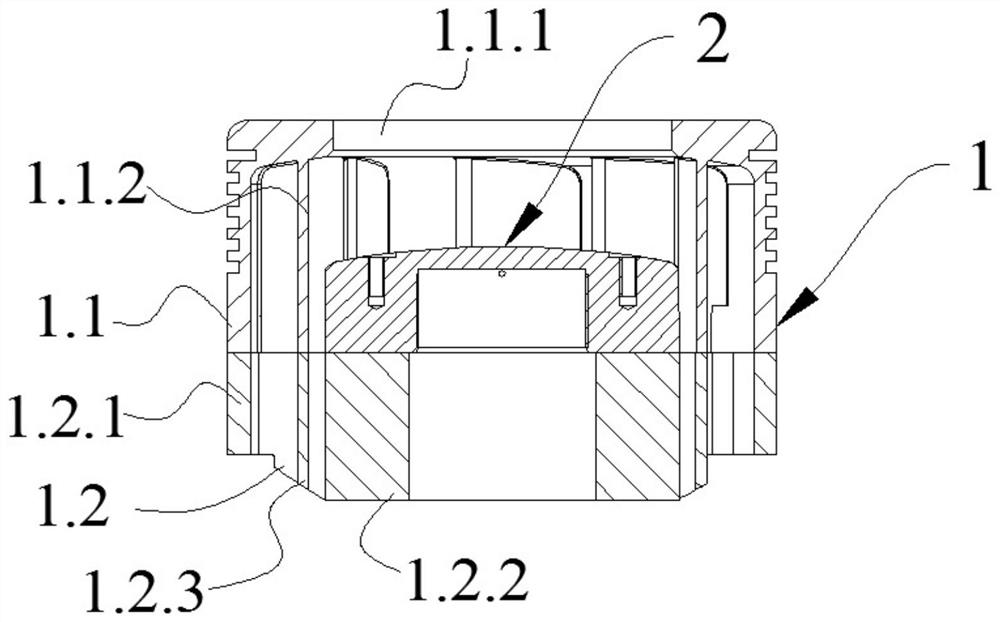

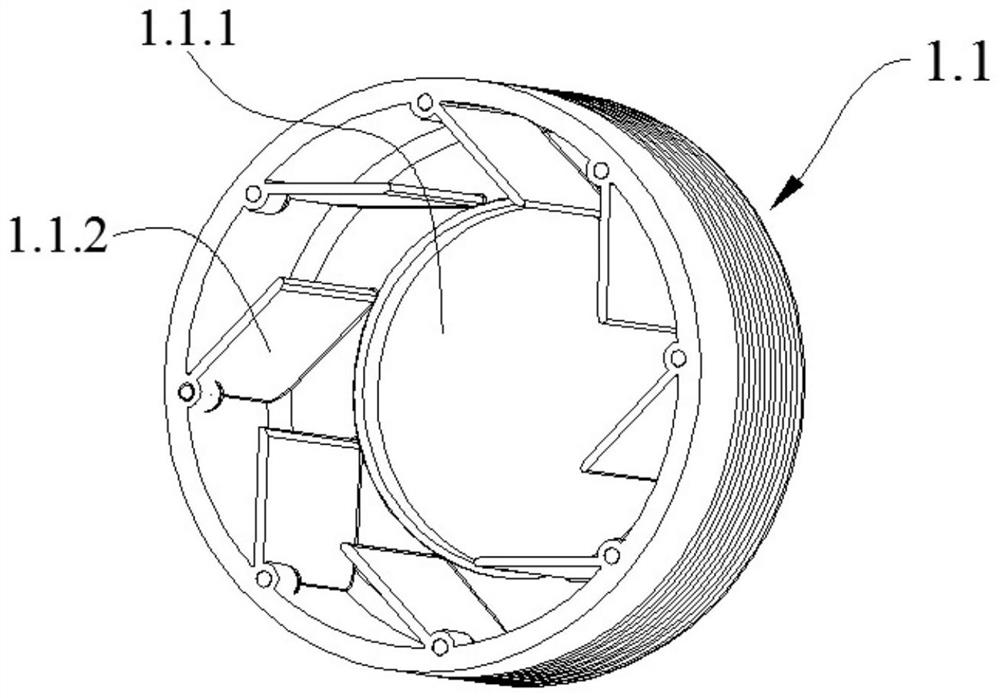

[0031] like Figure 2 to Figure 9 As shown, a new crosshead two-stroke direct-flow scavenging piston assembly is characterized in that it includes a scavenging piston 1 and an intake valve 2, and the scavenging piston 1 is composed of a detachable piston head 1.1 and a piston seat 1.2 Composed together, the intake valve 2 is located inside the scavenging piston 1 and is detachably connected to one end of the piston rod 3. The top center of the piston head 1.1 is provided with a scavenging port 1.1.1, and the intake valve 2 and the scavenging port 1.1 .1 Cooperate and realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com