Hardener for epoxy-resin adhesives

A technology of epoxy resin curing and epoxy resin, applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additives, etc., can solve the problems of insufficient adhesion, low glass transition temperature, etc., and achieve good processability properties, high glass transition temperature, and high adhesion

Pending Publication Date: 2021-05-11

SIKA TECH AG

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if such alkylated amines are used as curing agents for epoxy adhesives, they lead to insufficient adhesion, especially to steel, and low glass transition temperatures

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to 11

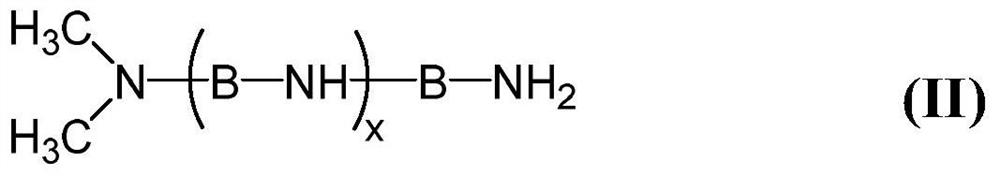

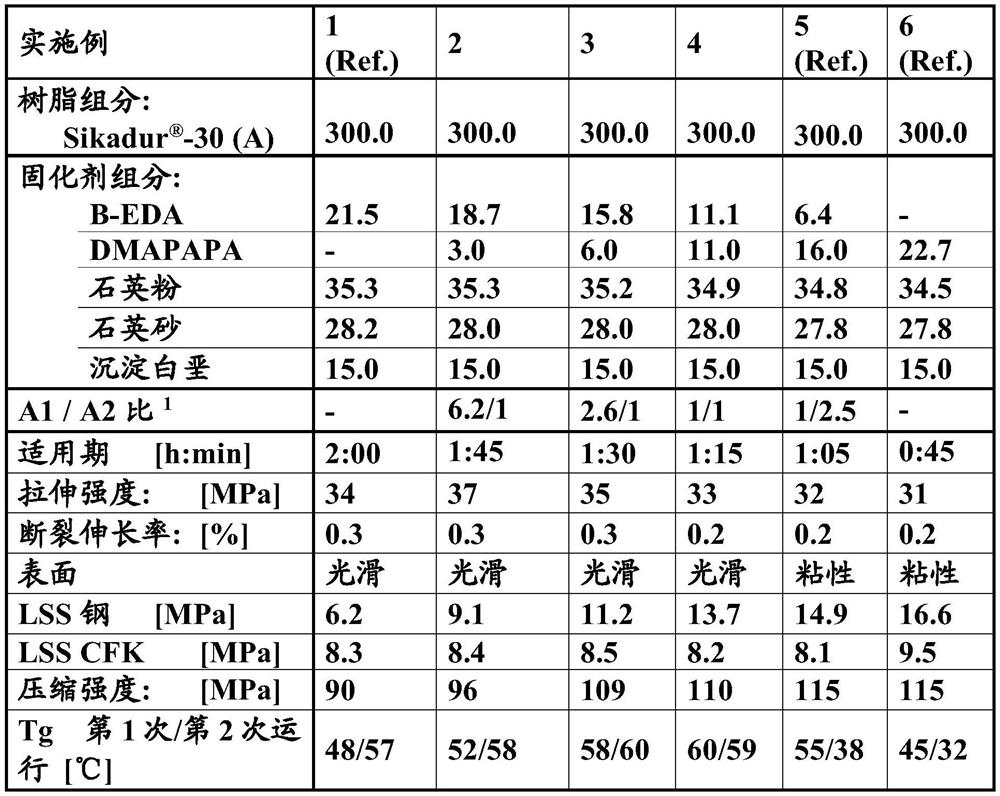

[0172] For each example, with the aid of a centrifugal mixer (SpeedMixer TM DAC 150, FlackTek Inc.), the ingredients of the curing agent components shown in Tables 1 to 2 were mixed in the indicated amounts (by parts by weight) and stored with the exclusion of moisture.

[0173] The resin components used are in the amounts (by weight) specified in Tables 1 and 2 - 30 Component A (from Sika).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

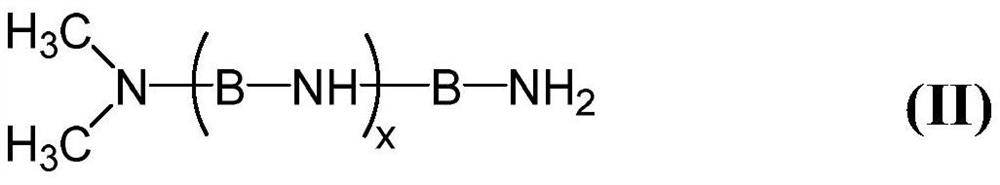

The present invention relates to a hardener for epoxy resins, containing at least one amine A1 of formula (I) and at least one amine A2 of formula (II), the weight ratio of amine A1 to amine A2 ranging between 20 / 1 and 1 / 2. The inventive hardener has a very low viscosity and is not susceptible to blushing. The hardener allows the manufacture of low-emission epoxy resin adhesives having good workability, a sufficiently long pot-life and open time with rapid curing, high strength, low brittleness, high adhesion, in particular to steel, and a sufficiently high glass transition temperature.

Description

technical field [0001] The invention relates to the field of epoxy resin curing agents, to epoxy resin adhesives and to their use for bonding, especially for bonding steel. Background technique [0002] Room temperature curable epoxy resin adhesives are used in many applications, e.g. for reinforcement of building structures with the aid of steel plates, for construction with the aid of precast concrete elements, for fastening components such as railings, handrails or door frames, or for repairs such as filling edges , holes or seams. For use in the construction industry, they must be usable under construction site conditions; for this, especially easy processability, and reliable and fast curing at outdoor ambient temperatures are important. In addition, they should have high strength and adhesion on typical construction materials such as concrete, steel and plastic. In order to have high adhesion, the adhesive must not be too brittle, since otherwise it could crumble eve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G59/50C09J163/00

CPCC08G59/5006C08G59/502C08G59/5033C09J163/00B32B37/12C08G59/245C08K3/36C08K9/04C09J5/00C09J11/04C09J2463/00

Inventor E·卡瑟米A·克拉默U·斯塔德尔曼U·布尔克哈特U·格伯

Owner SIKA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com