A discharge seeding method and a discharge seeding unmanned aerial vehicle using the method

An unmanned aerial vehicle and seed technology, applied in the field of agricultural aviation, can solve the problems of limited seeding speed, complex structure, and friction wheel jamming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] A kind of sowing method of row-type seeding drone, such as Figure 9 shown, including the following steps:

[0098] S1: Calibration parameters: Calibrate and store the control parameters of the row-type sowing;

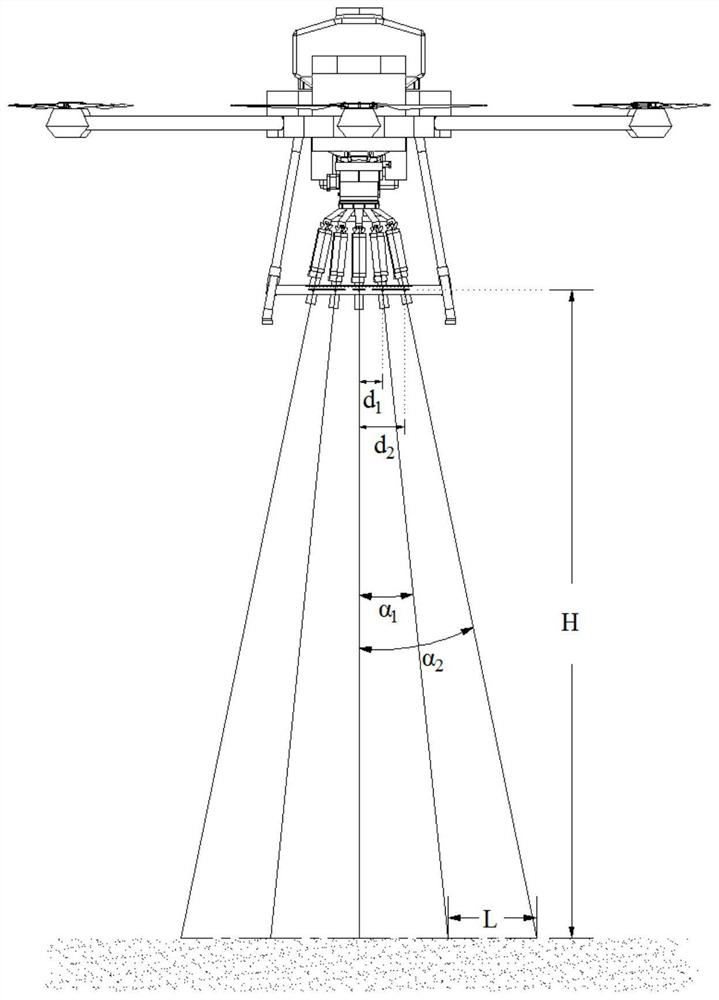

[0099] The row seeding control parameters are determined by the following relationship models: the relationship model between the working height, the shooting angle and the row spacing, the relationship model between the seeding frequency of the burst sowing module, the sowing operation speed and the plant spacing, the friction wheel speed, and the working height The relationship model with the depth of seed penetration into the soil;

[0100] S2: Centralized seed supply: when sowing, the seeds enter the seed meter from the seed box, and the seed discharge is controlled by the seed meter;

[0101] S3: Sowing by the seed divider: the seeds discharged by the seed meter are divided into multiple parts, and are guided and dispersed to each burst sowing module by ...

Embodiment 2

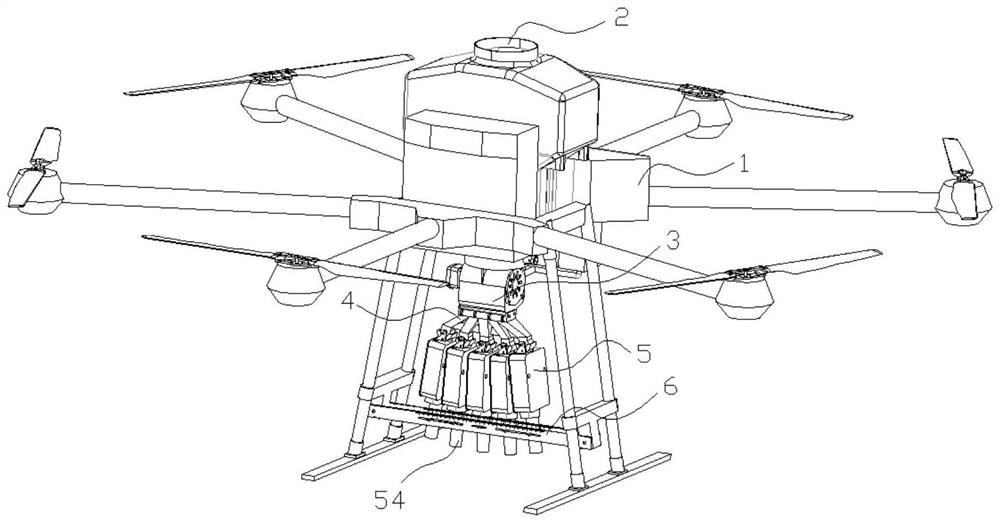

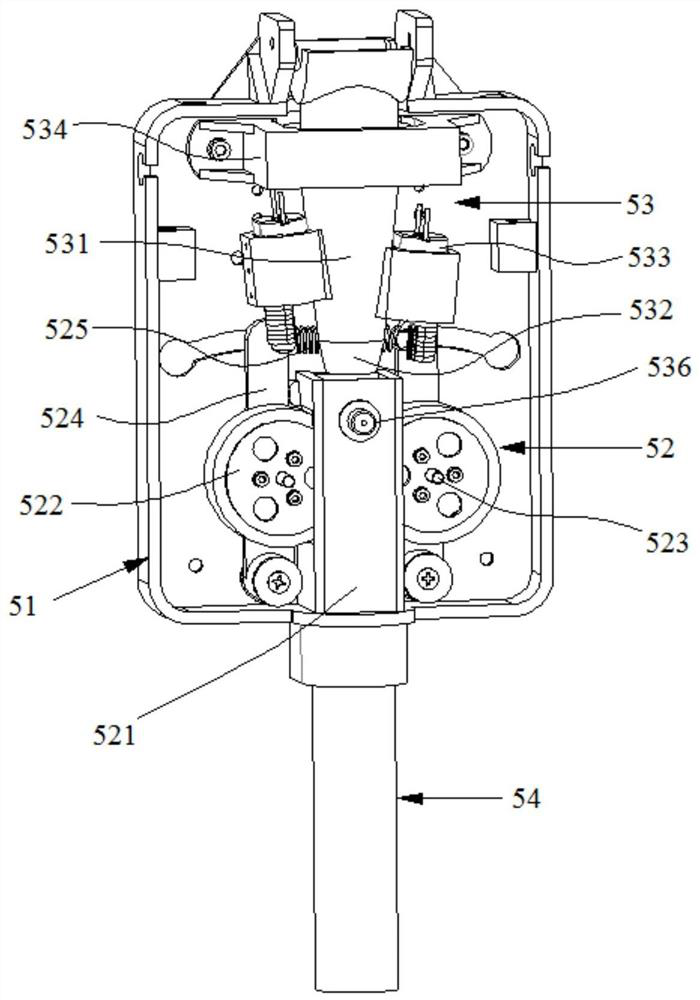

[0111] Such as figure 1 , a row-type seeding drone applied to the row-type sowing method, comprising a drone body 1, a seed box 2, a seed meter 3, a seed divider 4 and several The burst seeding module 5; the seed meter 3 is used to discharge the seeds to the seed divider 4; the seed divider 4 is used to disperse and transport the seeds to the corresponding burst seeding module 5; the burst seeding module 5 Distributed side by side in a fan shape, the burst seeding modules 5 are used for queuing up the seeds and accelerating their ejection.

[0112] In this embodiment, the row-type sowing UAVs are as follows from top to bottom: seed box 2, UAV body 1, seed meter 3, seed divider 4 and five burst seeding modules 5; The seeds in the box 2 are discharged into the seed divider 4 through the seed meter 3. The seed divider 4 divides the seeds into five parts and transmits them to the corresponding burst seeding module 5. The burst seeding module 5 can accelerate the seeds After inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com