Heat exchange medium uniform distribution device of U-shaped pipe organic silicon fluidized bed reactor

A technology of heat exchange medium and silicon fluidized bed, which is applied in chemical instruments and methods, chemical industry, chemical/physical processes, etc., can solve the problems of uneven distribution of heat exchange medium, high investment and operating costs, and achieve suppression of side reactions , reasonable structure and convenient equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments These are some embodiments of the present invention, but not all embodiments.

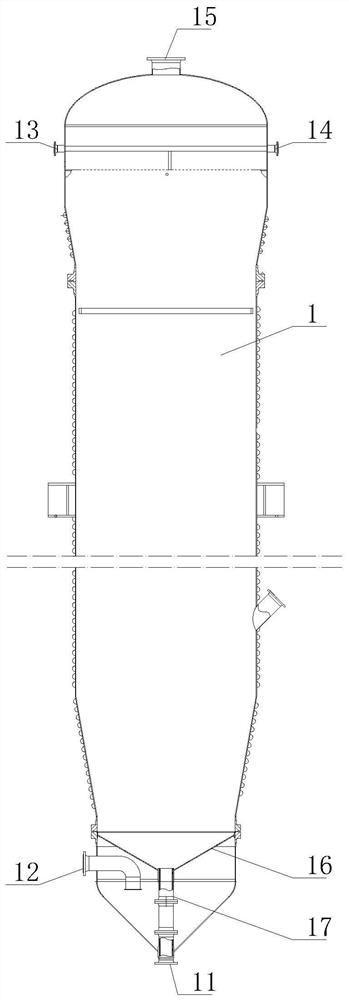

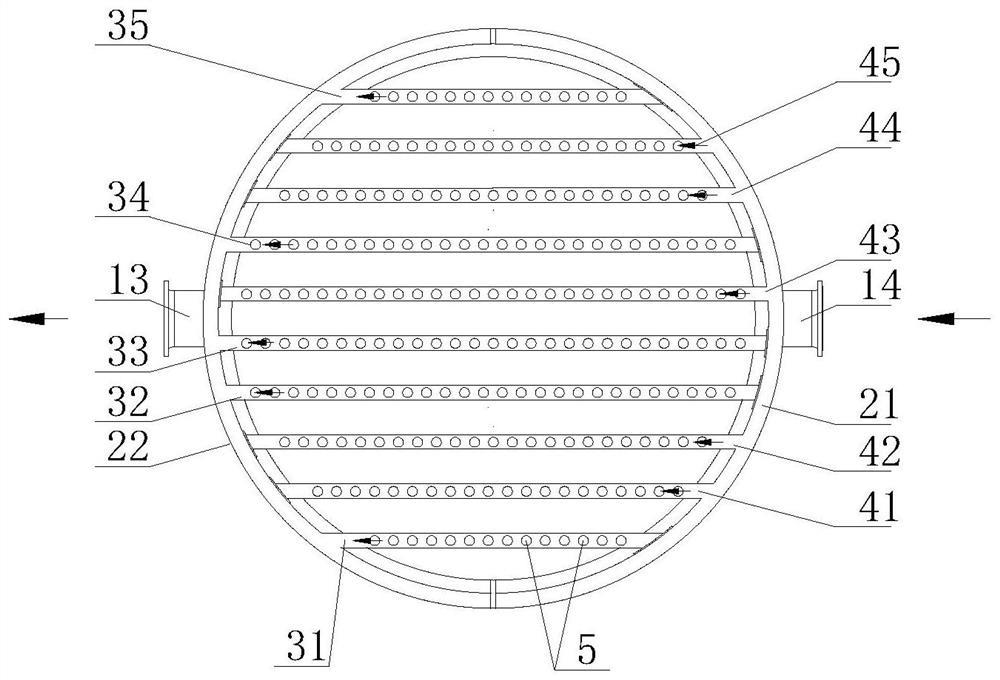

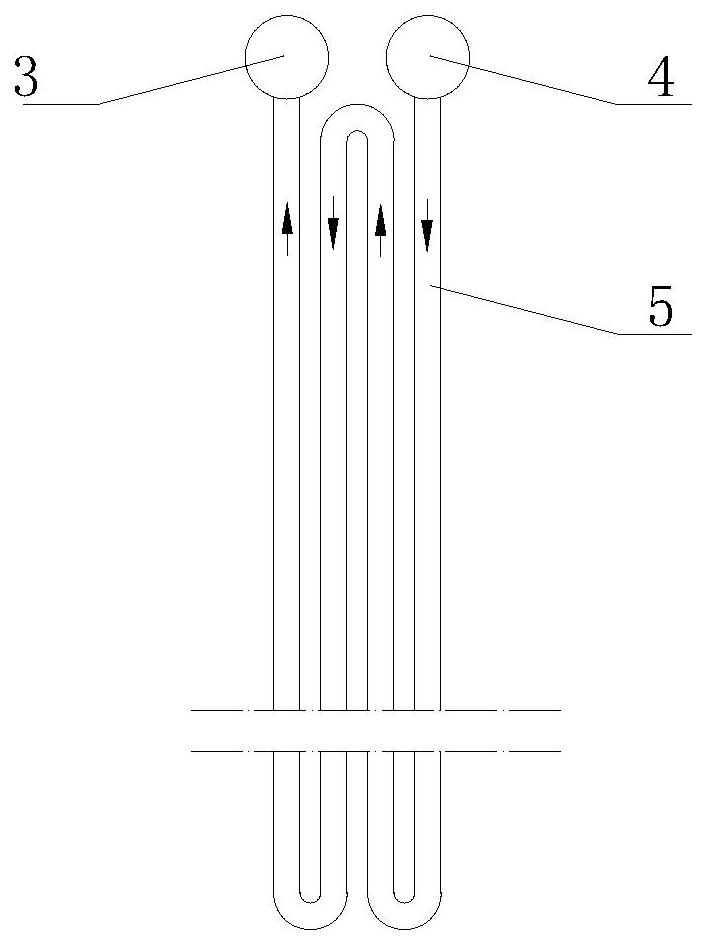

[0025] like Figure 1-Figure 3 As shown, the present embodiment discloses a heat exchange medium uniform distribution device for a U-tube organosilicon fluidized bed reactor, the fluidized bed reactor as a whole is a sealed cylinder 1 with a cavity inside. The bottom of 1 is provided with a silicon powder inlet 11, the top is provided with a crude monomer gas phase outlet 15, the lower part is provided with a methyl chloride gas inlet 12, and both sides of the upper part are provided with a heat exchange medium inlet 14 and a heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com