Nanotube photocatalytic bactericide as well as preparation method and application thereof

A nanotube and photocatalytic technology, applied in the direction of catalyst activation/preparation, bactericide, chemical instrument and method, etc., can solve the problem of no nanotube photocatalytic bactericide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

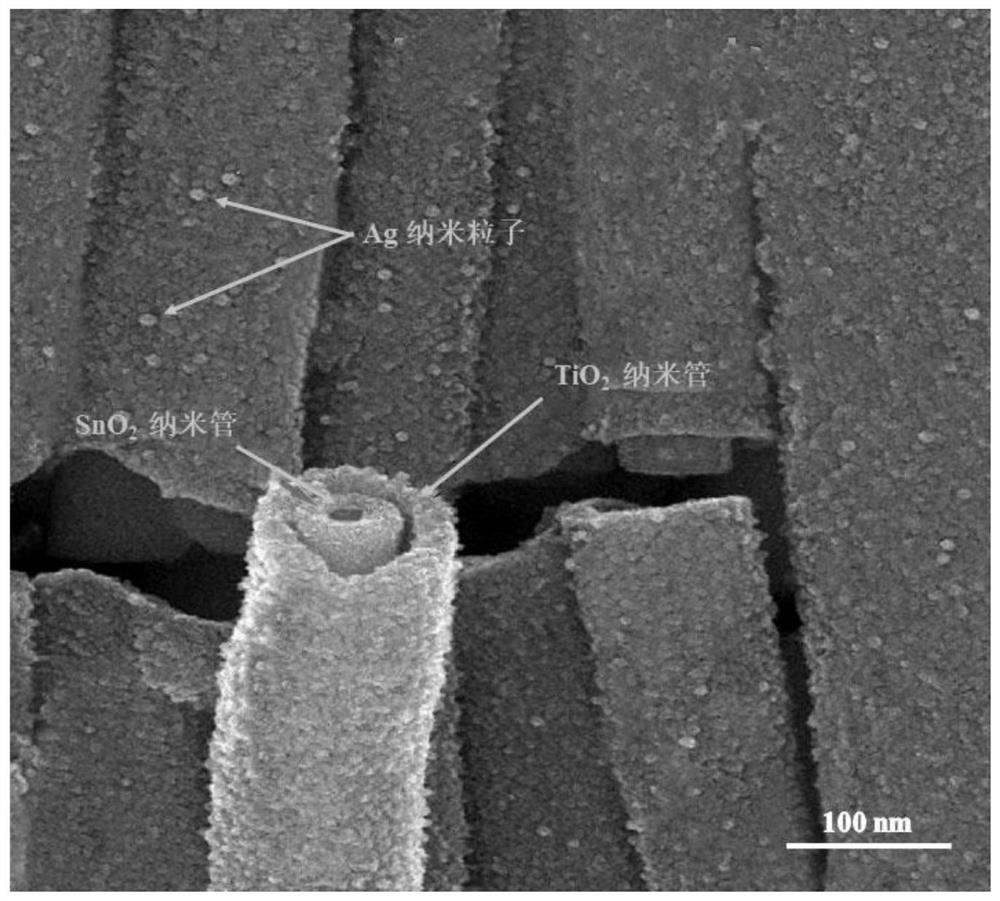

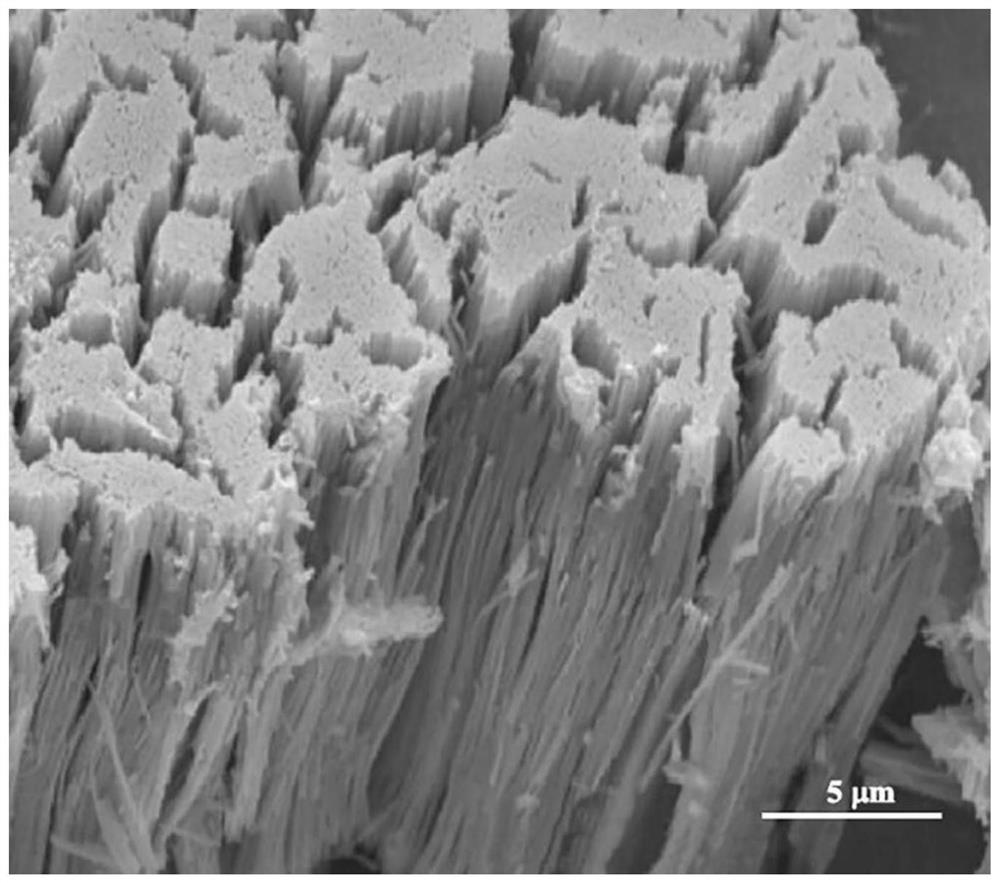

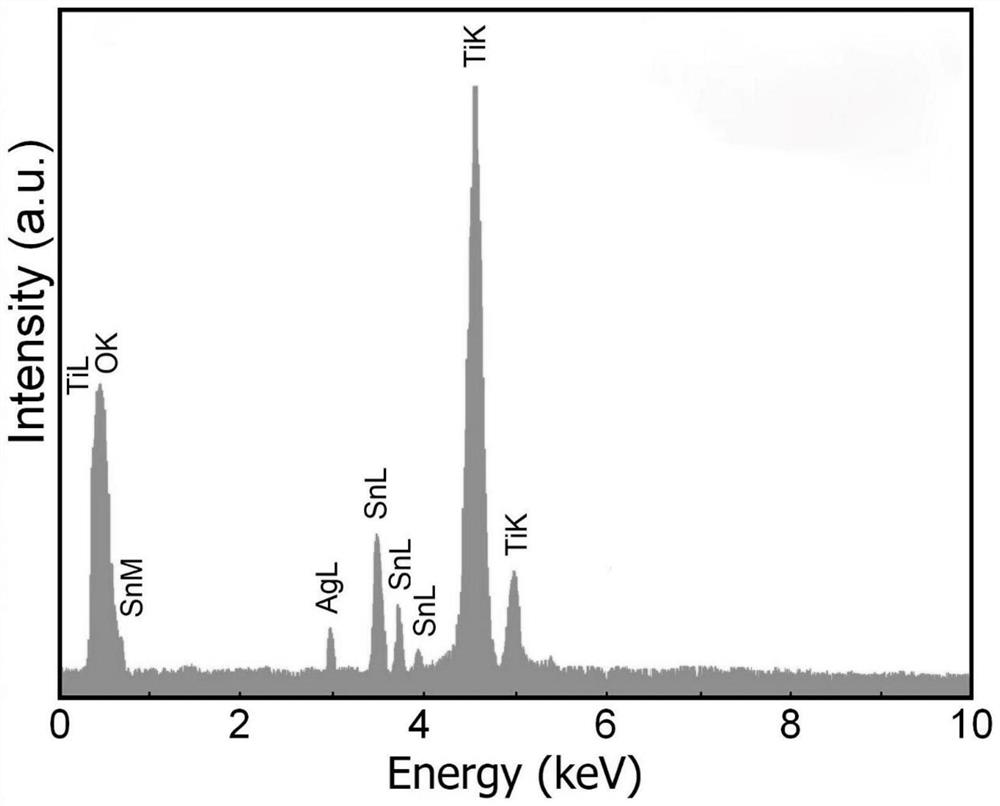

[0071] The preparation method of the nanotube photocatalytic bactericide of the present embodiment comprises the following steps:

[0072] Step 1: Preparation with SnO 2 Porous alumina templates for nanotubes

[0073] Take a porous alumina template, the porous alumina template is a single pass, the pore diameter is 30nm, the pore spacing is 65nm, and the pore depth is 5μm±0.2μm. Soak in SnCl with a concentration of 0.02mol / mL at a temperature of 25°C 4 ·5H 2 O aqueous solution for 4h.

[0074] From the above SnCl 4 ·5H 2 The porous alumina template was taken out from the O aqueous solution, and after calcination at a high temperature of 550 ° C for 2 h, the SnO 2 Porous alumina templates for nanotubes.

[0075] The above with SnO 2 The porous alumina template of nanotubes was first washed with absolute ethanol for 3 times, and then washed with distilled water for 3 times, and dried at 60 °C for 6 h to obtain the dried SnO 2 Porous alumina templates for nanotubes.

[...

Embodiment 2

[0087] The preparation method of the nanotube photocatalytic bactericide of the present embodiment comprises the following steps:

[0088] Step 1: Preparation with SnO 2 Porous alumina templates for nanotubes

[0089] Take a porous alumina template, the porous alumina template is a single pass, the pore diameter is 30nm, the pore spacing is 65nm, and the pore depth is 5μm±0.2μm. Soak in SnCl with a concentration of 0.5mol / mL at a temperature of 25°C-30°C 4 ·5H 2 O aqueous solution for 4h.

[0090] From the above SnCl 4 ·5H 2 The porous alumina template was taken out from the O aqueous solution, and after calcination at a high temperature of 550 ° C for 2 h, the SnO 2 Porous alumina templates for nanotubes.

[0091] The above with SnO 2 The porous alumina template of the nanotubes was first washed with absolute ethanol for 4 times, then washed with distilled water for 3 times, and dried at 60°C for 6 hours to obtain the dried SnO 2 Porous alumina templates for nanotube...

Embodiment 3

[0100] The preparation method of the nanotube photocatalytic bactericide of the present embodiment comprises the following steps:

[0101] Step 1: Preparation with SnO 2 Porous alumina templates for nanotubes

[0102] Take a porous alumina template, the porous alumina template is a single pass, the pore diameter is 30nm, the pore spacing is 65nm, and the pore depth is 5μm±0.2μm. Soak in SnCl with a concentration of 0.1mol / mL at a temperature of 25°C-30°C 4 ·5H 2 O aqueous solution for 4h.

[0103] From the above SnCl 4 ·5H 2 The porous alumina template was taken out from the O aqueous solution, and after calcination at a high temperature of 550 ° C for 2 h, the SnO 2 Porous alumina templates for nanotubes.

[0104] The above with SnO 2 The porous alumina template of the nanotubes was first washed with absolute ethanol for 3 times, then washed with distilled water for 4 times, and dried at 60 °C for 6 h to obtain the dried SnO 2 Porous alumina templates for nanotubes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com