Shale gas well drilling waste oil-based mud curing material

A technology for oil-based mud and solidified materials, which is used in fixed/solidified sludge treatment, sludge treatment, chemical instruments and methods, etc., and can solve the problems of accelerated damage to mixing equipment, inability to continue work, and long processing time. Achieve the effect of protecting mixing equipment, accelerating coagulation speed and working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

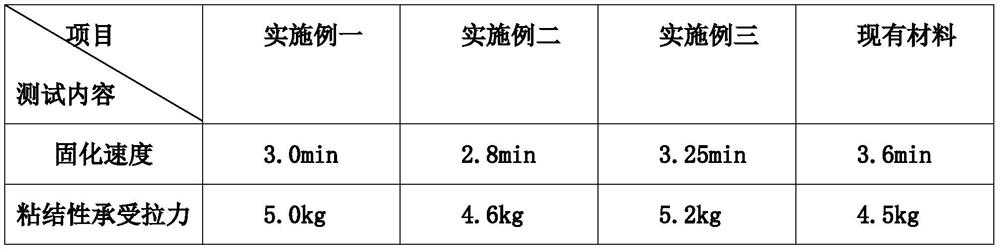

[0028] A shale gas well drilling waste oil-based mud solidification material, its raw materials include by weight: 45% oil-based mud, 35% sand, 0.3% curing agent, 18.1% water, and 1.6% flocculant.

[0029] 1. The curing agent can be used:

[0030] (1) Alkaline and acidic curing agents:

[0031] ①Basic curing agent: including aliphatic diamines and polyamines, aromatic polyamines, other nitrogen-containing compounds and modified fatty amines;

[0032] ② Acidic curing agent: including organic acids, acid anhydrides, and boron trifluoride and its complexes;

[0033] (2) Addition and catalytic curing agents:

[0034] ① Addition type curing agent: This type of curing agent undergoes an addition reaction with the epoxy group to form a part of the cured product chain segment, and through a gradual polymerization reaction, the linear molecules are cross-linked into body-type structural molecules. This type of curing agent is also called melon type curing agent. Such as primary amine...

Embodiment 2

[0110] A shale gas well drilling waste oil-based mud solidification material, the raw materials of which include by weight: 60% oil-based mud, 30% sand, 5% curing agent, 13.8% water, and 1.2% flocculant.

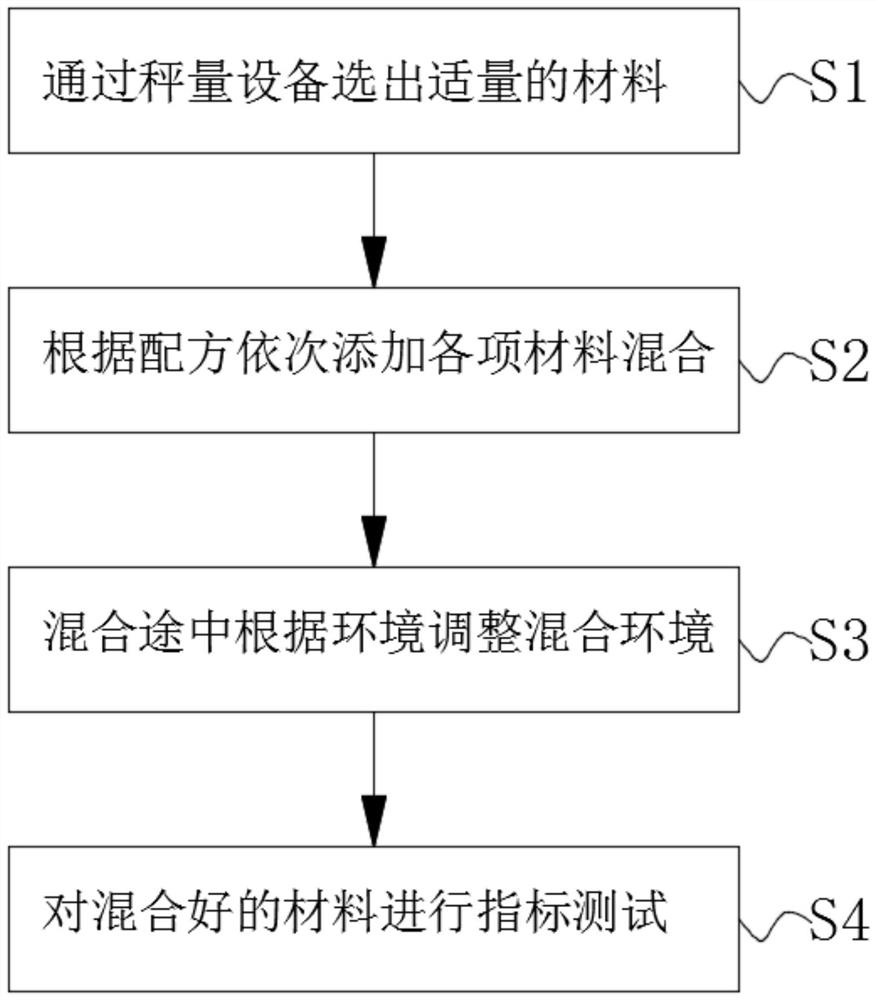

[0111] S1. First, prepare all the materials and put them aside, and then filter the materials that need to be tested. The materials used for the test are: 60% oil-based mud, 30% sand, 5% curing agent, and 13.8% water , flocculant 1.2%, and then filter the impurities and larger lumps through the screening method to make the material more pure and clean, then weigh according to different formulas, weigh out the corresponding proportion, and then sequentially Put it away.

[0112] S2. Put various materials into the stirring and mixing equipment in sequence according to the proportioning order, start the mixing equipment at the same time, stir and mix these materials, wait until the mixing equipment completely mixes all the materials evenly and internally After there is no aggl...

Embodiment 3

[0116] A shale gas well drilling waste oil-based mud solidification material, the raw materials of which include by weight: 50% oil-based mud, 23.8% sand, 4% curing agent, 18% water, and 4.2% flocculant.

[0117] S1. First, prepare all the materials and put them aside, and then filter the materials that need to be tested. The materials used for the test are: 50% oil-based mud, 23.8% sand, 4% curing agent, and 18% water , flocculant 4.2%, and then filter the impurities and larger lumps through the screening method to make the material more pure and clean, then weigh according to different formulas, weigh out the corresponding proportion, and then sequentially code put away;

[0118] S2. Put various materials into the stirring and mixing equipment in sequence according to the proportioning order, start the mixing equipment at the same time, stir and mix these materials, wait until the mixing equipment completely mixes all the materials evenly and internally After there is no ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com