Sludge drying device

A sludge drying and drying technology, applied in dewatering/drying/concentrating sludge treatment, transportation and packaging, chemical instruments and methods, etc., can solve the problem of uneven drying, poor drying effect and low drying efficiency and other problems, to achieve the effect of good drying effect, fast replacement speed and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

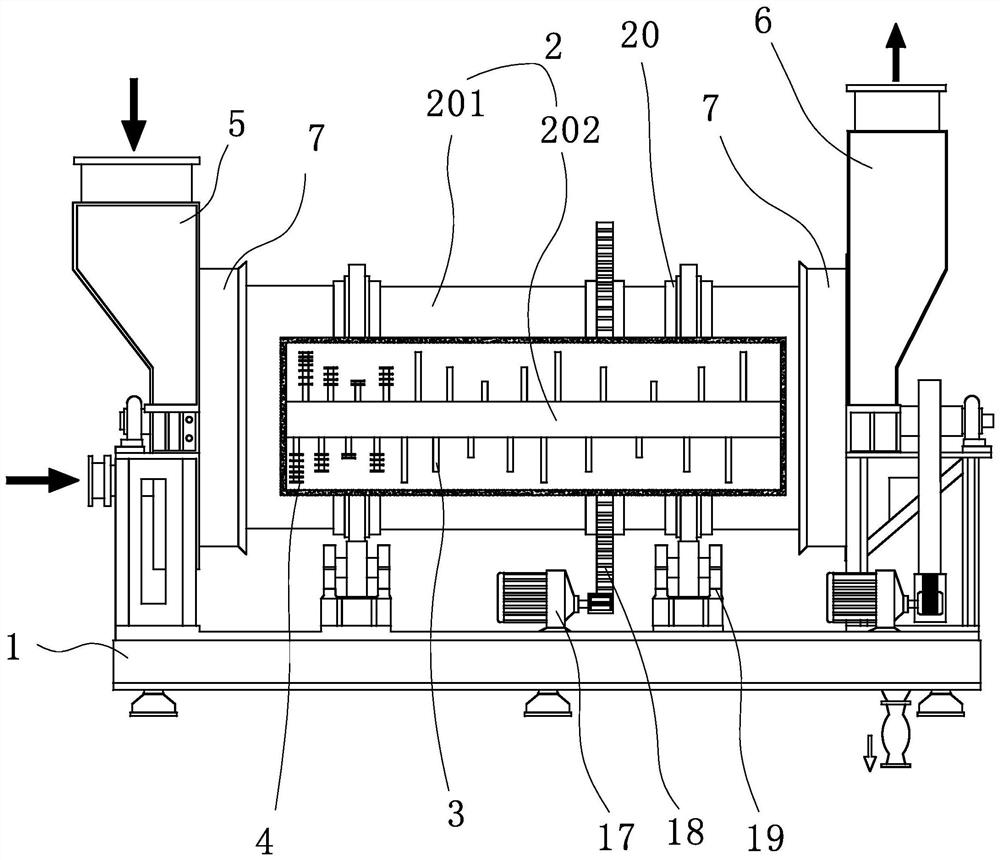

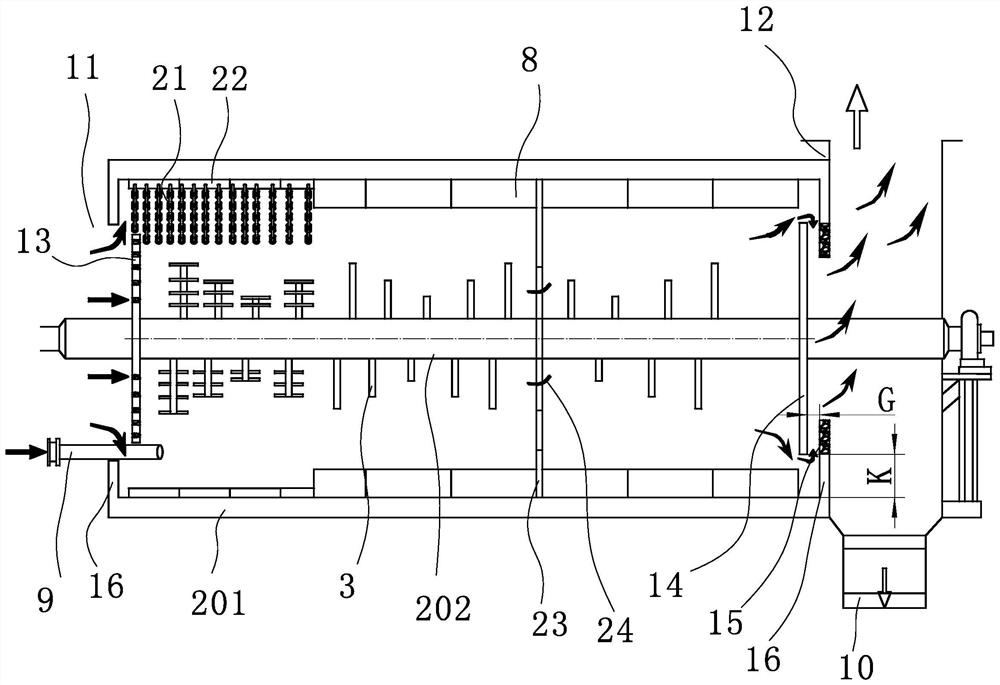

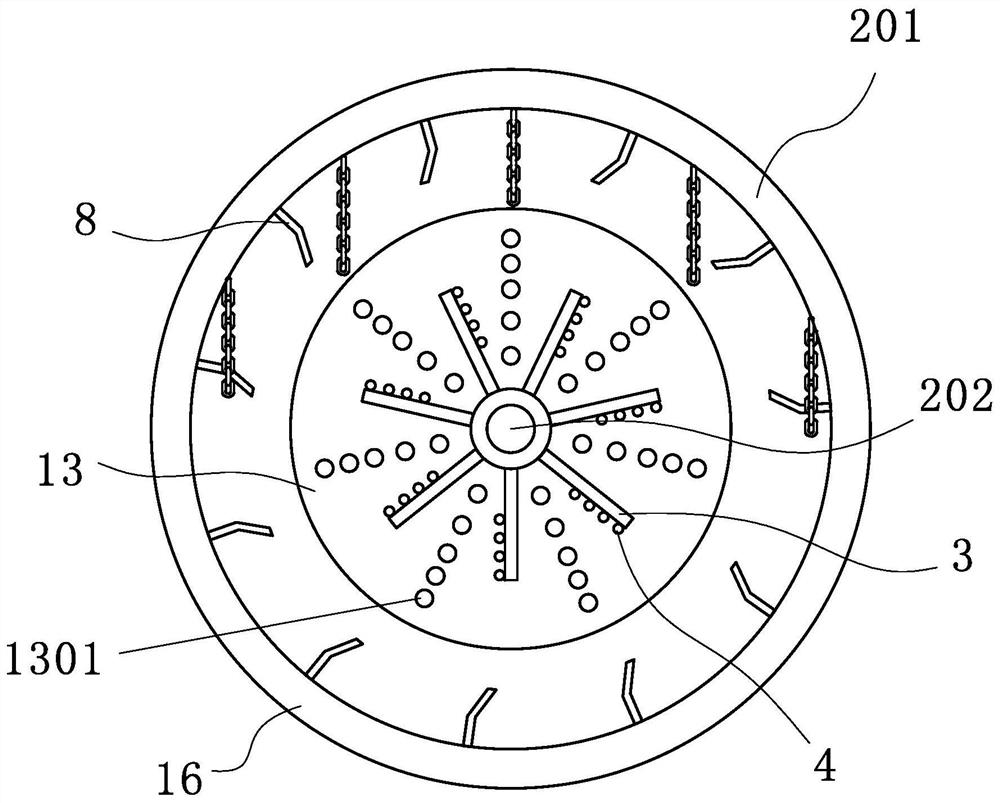

[0026] Such as figure 1 , figure 2 In the shown embodiment 1, a sludge drying device includes a drying drum 2. The drying drum 2 includes a horizontally arranged outer drum 201 and an inner rotor 202 arranged inside the outer drum 201. The drum 201 and the inner rotor 202 are in the same direction, and the inner rotor 202 is provided with a number of stirring rods 3 arranged in a double helix shape, and an auxiliary crushing structure is arranged on the inner wall of the outer drum 201 to dry the drum. 2 The two ends are the inlet port 11 and the outlet port 12 respectively. The inlet port 11 is connected to the inlet chamber 5 for receiving hot flue gas, and the outlet port 12 is connected to the outlet chamber 6 for discharging low-temperature hot flue gas. At the inlet port 11 The bottom is also provided with a feed port 9, and a discharge port 10 is provided at the bottom of the outlet end 12. The drying drum 2 is successively divided into a front section, a middle secti...

Embodiment 2

[0035] Such as figure 2 As shown, the technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, and the difference is that the auxiliary crushing structure includes a chain 22 and a lifting plate 8 arranged on the inner wall surface of the outer drum 201, and in the outer drum 201 The front section of the wall is provided with a chain fixing plate 21, the chain 22 is fixed on the chain fixing plate 21, and the lifting plate 8 is arranged on the outer drum 201 of the middle section and the rear section. In the front section of the drying drum 2, the material is a large piece of wet material, and the setting of the chain 22 is beneficial to prevent the adhesion of the wet material, and at the same time has the function of breaking the wet material, and the chain 22 is detachably connected to the outer drum 201. The disassembly and replacement of the chain 22 is realized, and the thickness of the chain 22 is conveniently determined accor...

Embodiment 3

[0037] The technical solution of embodiment 3 is basically the same as the technical solution of embodiment 1, and the difference is that the stirring rod 3 in the front section is a semi-cylindrical structure, and the plane of the stirring rod 3 faces the side of the inlet end 11, and the semicircular surface faces One side of the outlet port 12. Such setting is beneficial to push the material to move toward the outlet end 12, ensure that the material moves toward the outlet as much as possible, and reduce the probability of the material splashing toward the inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com