Preparation method of silicone rubber with polar functional groups

A technology of polar functional groups and silicone rubber, which is applied in the field of preparing silicone rubber, can solve the problems of non-curing of silicone rubber, increase of curing time of silicone rubber composition, and catalyst failure, so as to prevent catalyst poisoning, broaden the scope of use, and solve the problem of polarity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

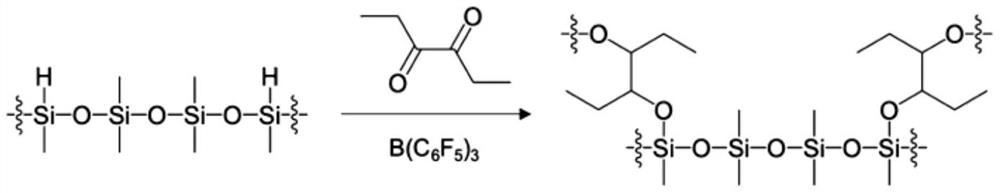

Embodiment 1

[0021]

[0022] Mix 100 parts by mass of organohydrogenpolysiloxane (Si-H content 1%), 0.5 parts by mass of crosslinking agent diacetyl, 0.05 parts by mass of catalyst tris(pentafluorophenyl) boron, and 0.1 part by mass of acetophenone uniform. At room temperature (20° C.), stand for 2 hours to obtain a cross-linked silicone rubber. The silicone rubber prepared by the non-metallic catalyst is transparent in color.

Embodiment 2

[0024] 100 parts by mass of organohydrogen polysiloxane (Si-H content 8%), 5 parts by mass of crosslinking agent 1-phenyl-1,2-propanedione, 0.2 parts by mass of catalyst trimethyl boron, and 0.5 parts by mass of part 4-hexen-3-one, mix well. Stand at 40°C for 2 hours to obtain a cross-linked silicone rubber.

Embodiment 3

[0026] 100 parts by mass of organohydrogenpolysiloxane (Si-H content 8%), 3 parts by mass of crosslinking agent 3,4-hexanedione, 0.01 part by mass of catalyst tris(pentafluorophenyl) boron, and 0.5 parts by mass of 4 - Acetylbenzonitrile, mix well. Stand at 40°C for 2 hours to obtain a cross-linked silicone rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com