Method for removing sulfur dioxide in exhaust gas

A technology of sulfur dioxide and fumed silica, which is applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as the ability to adsorb sulfur dioxide that have not been mentioned, and achieve the reduction of conditional guarantee consumption, reduction of recovery costs, and adsorption capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

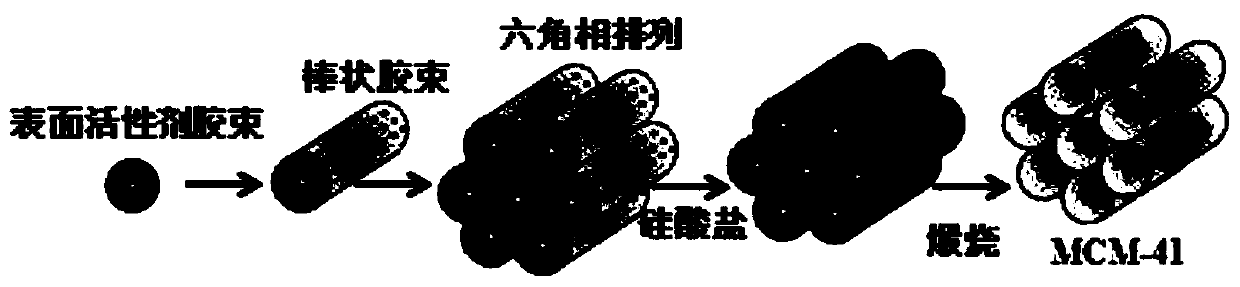

Method used

Image

Examples

Embodiment example 1-1

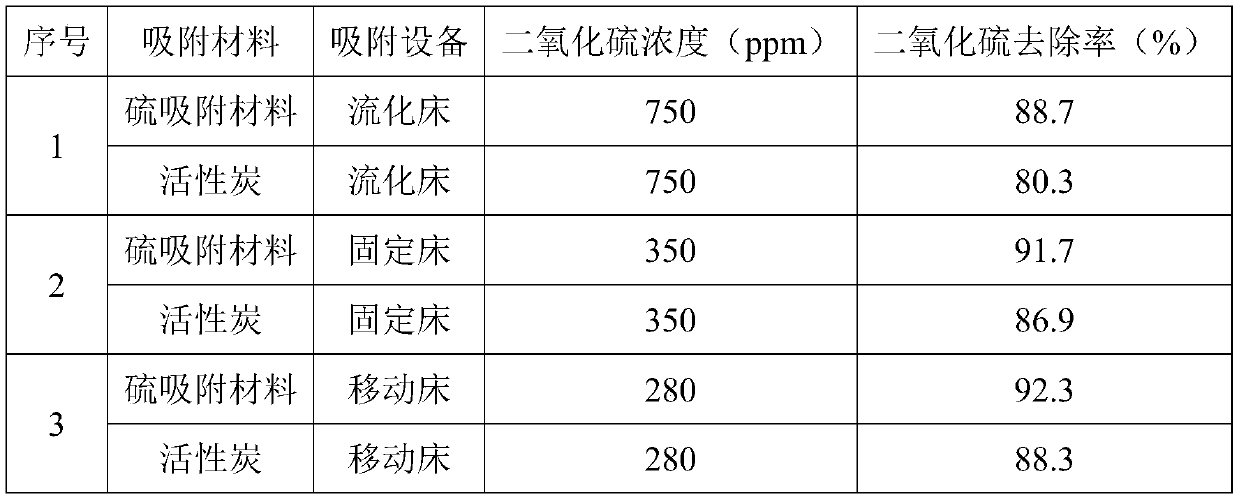

[0039] Using the sulfur dioxide adsorbent prepared in Example 1, a method for removing sulfur dioxide in the flue gas of the present invention: carry out in a fluidized bed, make the flue gas fully contact with the adsorbent, the flue gas flow rate is 2.0L / min, and the flue gas The concentration of sulfur dioxide is 500ppm, and the adsorption temperature is 350°C. The contact pressure is 0.15MPa, the adsorption cycle is 24 hours, the sulfur dioxide removal rate is 88.7%, and the sulfur adsorption capacity is 5.5%.

Embodiment example 1-2

[0041] Using the sulfur dioxide adsorbent prepared in Example 2, a method for removing sulfur dioxide in the flue gas of the present invention: carry out in a fluidized bed, make the flue gas fully contact with the adsorbent, the flue gas flow rate is 3.0L / min, and the flue gas The concentration of sulfur dioxide is 750ppm, and the adsorption temperature is 500°C. The contact pressure is 0.25MPa, the adsorption cycle is 28 hours, the sulfur dioxide removal rate is 90.3%, and the sulfur adsorption capacity is 5.7%.

Embodiment example 2-1

[0043] Using the sulfur dioxide adsorbent prepared in Example 1, a method for removing sulfur dioxide in the flue gas of the present invention: carry out in a fixed bed, make the flue gas fully contact with the adsorbent, the flue gas flow rate is 5.0L / min, and the sulfur dioxide in the flue gas The concentration is 350ppm, and the adsorption temperature is 400°C. The contact pressure is 0.18MPa, the adsorption cycle is 12 hours, the sulfur dioxide removal rate is 91.7%, and the sulfur adsorption capacity is 5.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com