Self-lubricating ABS composite material for lipstick pen and preparation method of self-lubricating ABS composite material

A composite material and self-lubricating technology, which is applied in the field of self-lubricating ABS composite materials for lipstick pens and their preparation, can solve other problems such as reduced performance, sticking, and large friction coefficient of the casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

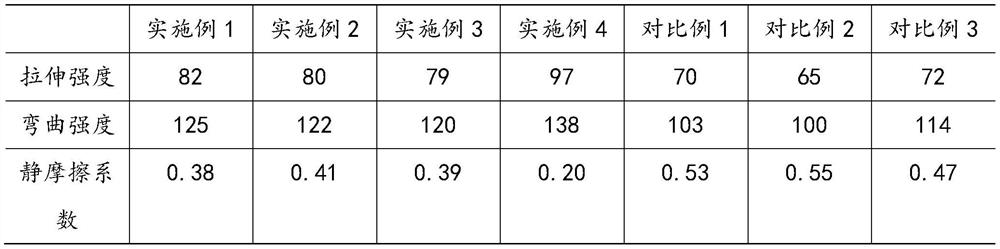

Examples

Embodiment 1

[0047] Prepare the ABS composite material, comprising the following steps

[0048] 1) Mix 0.8 parts of calcium fluoride powder coated with Ni-B alloy, 3 parts of polytetrafluoroethylene micropowder, and 7 parts of glass fiber, and place them in an alcohol solution of 0.1 part of coupling agent, stir, and then dry;

[0049] 2) Mix 75 parts of ABS resin with the final product in step 1), 0.5 parts of silicone oil, 1 part of compatibilizer, 0.3 parts of antioxidant, and 0.1 part of stabilizer, and place them in a screw extruder to granulate to obtain ABS resin compound Material masterbatch.

Embodiment 2

[0051] Prepare the ABS composite material, comprising the following steps

[0052] 1), mix 2 parts of calcium fluoride powder coated with Ni-B alloy, 5 parts of polytetrafluoroethylene micropowder, and 12 parts of glass fiber, and place them in an alcohol solution of 0.2 parts of coupling agent, stir, and then dry;

[0053] 2) Mix 87 parts of ABS resin with the final product in step 1), 1 part of silicone oil, 3 parts of compatibilizer, 0.6 part of antioxidant, and 0.3 part of stabilizer, and place them in a screw extruder for granulation to obtain ABS resin Composite material masterbatch.

Embodiment 3

[0055] Prepare the ABS composite material, comprising the following steps

[0056] 1) Mix 1 part of calcium fluoride powder coated with Ni-B alloy, 4 parts of polytetrafluoroethylene micropowder, and 10 parts of glass fiber, and place them in an alcohol solution of 0.3 parts of coupling agent, stir, and then dry;

[0057] 2) Mix 80 parts of ABS resin with the final product in step 1), 0.7 parts of silicone oil, 2 parts of compatibilizer, 0.5 parts of antioxidant, and 0.2 parts of stabilizer, and place them in a screw extruder for granulation to obtain ABS resin Composite material masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com