Glass fiber rope for reinforcing polyethylene pipeline and preparation method of glass fiber rope

A technology of glass fiber rope and glass fiber, which is applied in the field of glass fiber rope and its preparation for reinforced polyethylene pipes, can solve the problems of glass fiber and polyethylene compounding difficulties, etc., and achieve light weight, good toughness and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

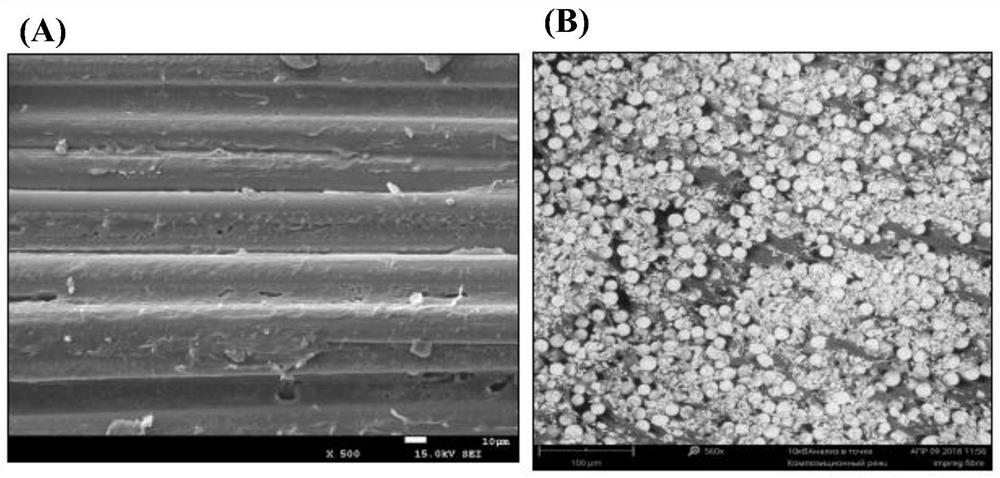

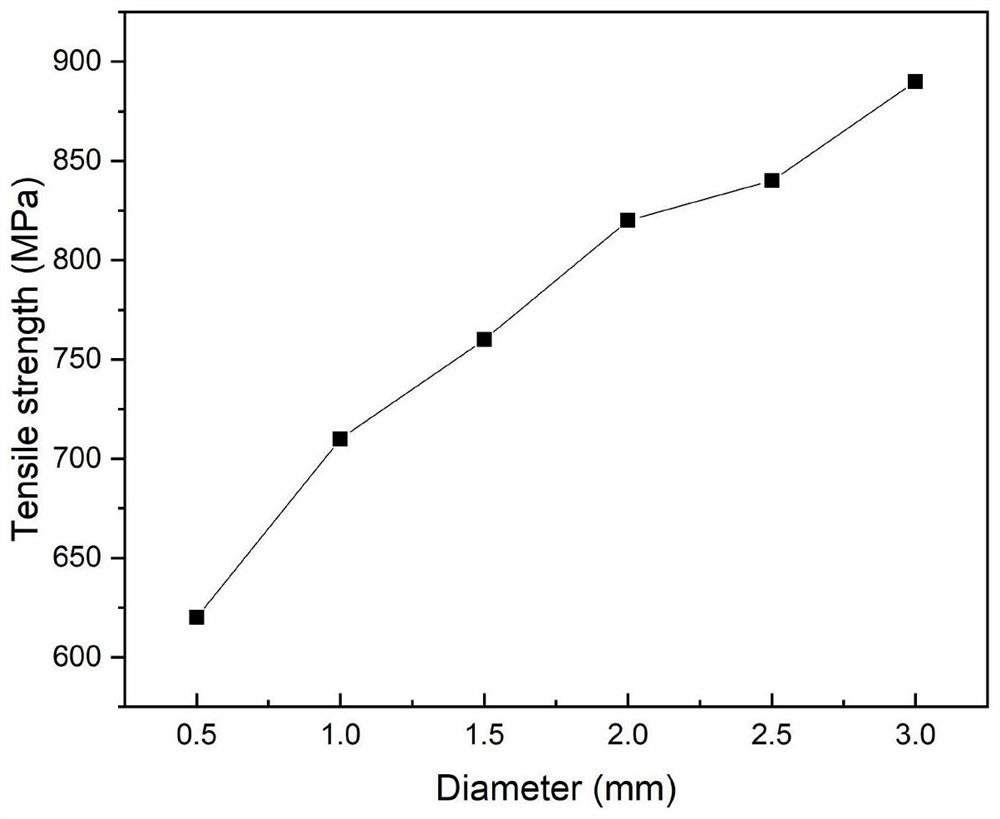

[0024] A glass fiber rope for reinforcing polyethylene pipes, the surface of the alkali-free glass fiber bundles of the glass fiber rope is coated with a layer of modified polyethylene, the mass percentage of the alkali-free glass fiber is 60-85%, and the glass fiber rope The diameter is 0.5-3mm, the single fiber diameter of the glass fiber bundle is 10-24μm, the thickness of the alkali-free glass fiber bundle is 600-4800tex (Tex), and the strength of the glass fiber rope is greater than 800MPa.

[0025] The modified polyethylene comprises the following components in parts by weight: 100 parts of HDPE (High DensityPolyethylene, high-density polyethylene), 20 parts of PA6 (Polyamide 6, nylon 6), 30 parts of TPV (Thermoplastic Vulcanizate, thermoplastic vulcanizate), 10 parts EPDM (Ethylene Propylene Diene Monomer, EPDM). Among them, HDPE is the matrix resin, PA6 is added to enhance the strength of the matrix resin, TPV is added to reduce the viscosity of the matrix resin and im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap