Fuel cell chemical regenerative heat gas turbine reheating type combined cycle system

A technology of fuel cells and gas turbines, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of low efficiency, achieve the effects of reducing emissions, increasing output power and thermal efficiency, and improving combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]It should be noted that the features in the present invention in the present invention can be combined with each other in the case of an unable conflict.

[0024]The present invention will be described in detail below with reference to the drawings.

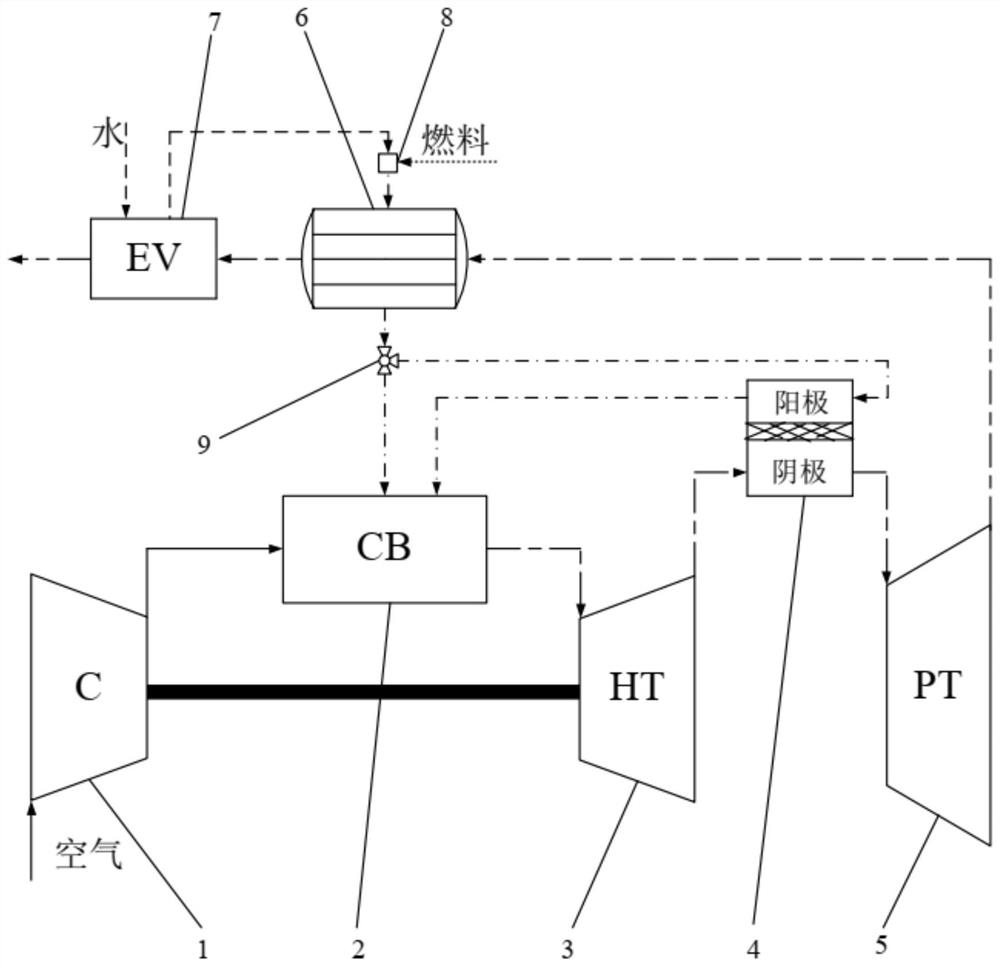

[0025]Such asfigure 1As shown, the fuel cell chemical returns the heat turbine reheat the combination cycle system, including the compressor 1, the combustion chamber 2, the high pressure turbine 3, the solid oxide fuel cell 4, the low pressure turbine 5, the chemical refolder 6, the evaporator 7, Mixer 8 and splitter 9;

[0026]The inlet of the air self-compressor 1 enters the compressor 1, the outlet of the compressor 1 is in communication with the first inlet of the combustion chamber 2, and the outlet of the combustion chamber 2 communicates with the inlet of the high pressure turbine 3, the compressor 1 and the high pressure turbine 3 Through the shaft connection, the outlet of the high pressure turbine 3 is connected to the cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com