Radiation refrigeration film and product provided with same

A technology for radiation refrigeration and products, applied in the field of radiation refrigeration films and their products, can solve the problems of increasing water and oxygen permeability, reducing colloidal cohesion, and reducing colloidal cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

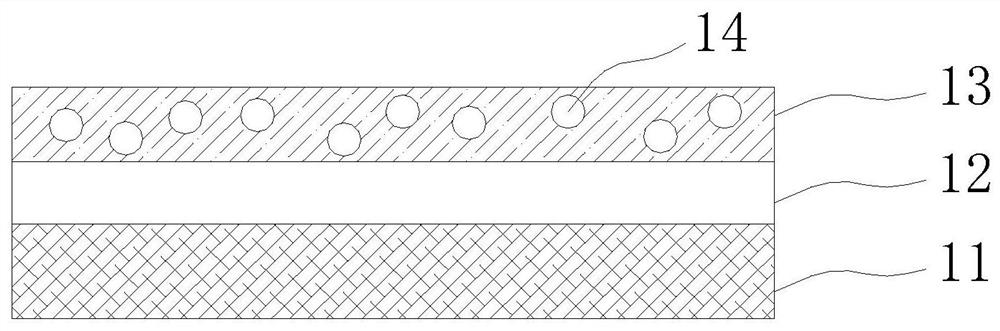

[0069] A polyethylene terephthalate film with a thickness of 30 μm is used as a carrier layer. After the carrier layer is placed at 120° C. for 30 minutes, the heat shrinkage rate in the transverse direction is 1.2%, and the heat shrinkage rate in the longitudinal direction is 1.4%. Magnetron sputtering on one surface of the carrier layer to obtain a silver reflective layer with a thickness of 100 nm, and then coating polytetrafluoroethylene resin on the surface of the carrier layer away from the silver reflective layer, and curing it into a 50 μm emissive layer, Obtain a radiative cooling film.

Embodiment 2

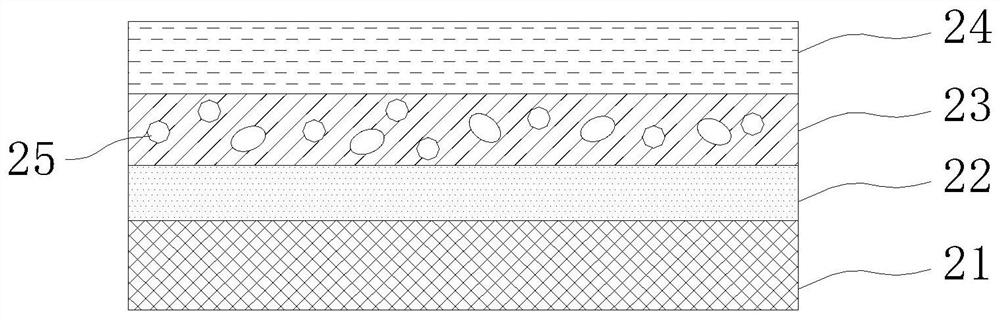

[0071] A polyethylene terephthalate film with a thickness of 30 μm is used as a carrier layer. After the carrier layer is placed at 120° C. for 30 minutes, the heat shrinkage rate in the transverse direction is 1.2%, and the heat shrinkage rate in the longitudinal direction is 1.4%. A silver reflective layer with a thickness of 100 nm was obtained by magnetron sputtering on the carrier layer, and then a polytetrafluoroethylene resin was coated on the silver reflective layer, and cured to form an emission layer with a thickness of 50 μm to obtain a radiation cooling film.

Embodiment 3

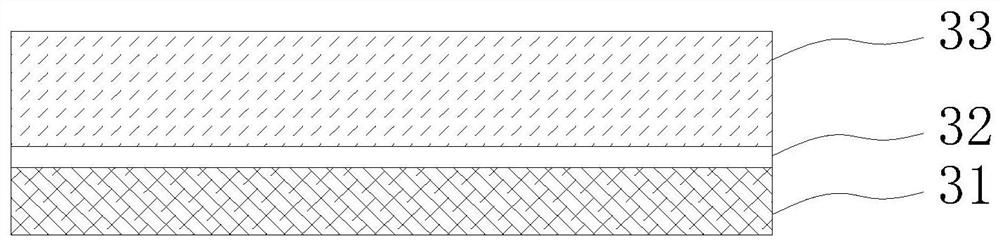

[0073] The difference between Example 3 and Example 1 is that a polytetrafluoroethylene film with a thickness of 50 μm is bonded to the surface of the carrier layer through a polyurethane adhesive layer with a thickness of 10 μm to obtain a radiative cooling film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com