Condensation heat recovery system for power plant

A recovery system and condensation heat technology, applied in heat pumps, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of accelerating the corrosion rate of related pipelines and equipment, increasing the supercooling degree of condensed water, and increasing the oxygen content of condensed water and other problems, to achieve the effect of increasing the speed, balancing the cooling effect, and reducing the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

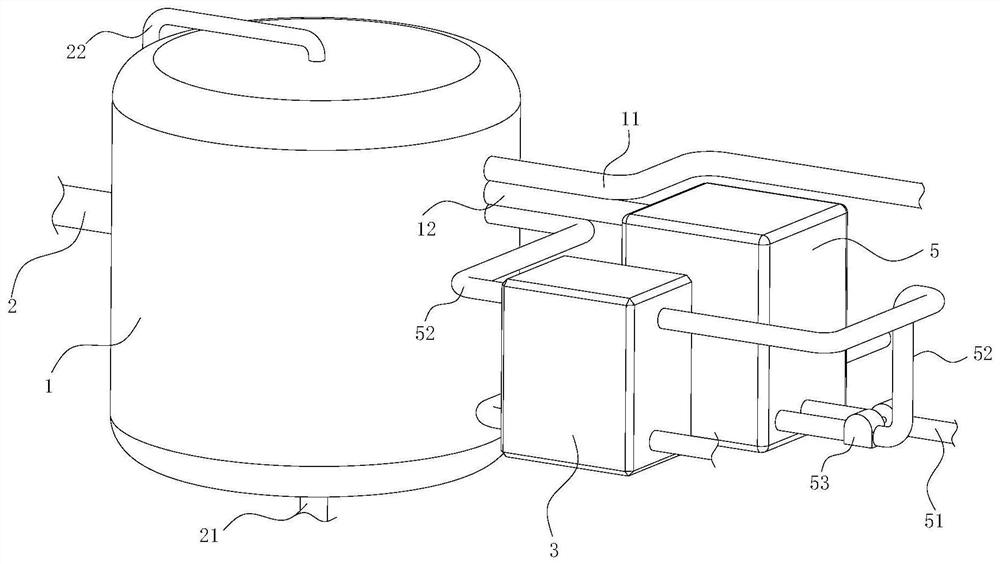

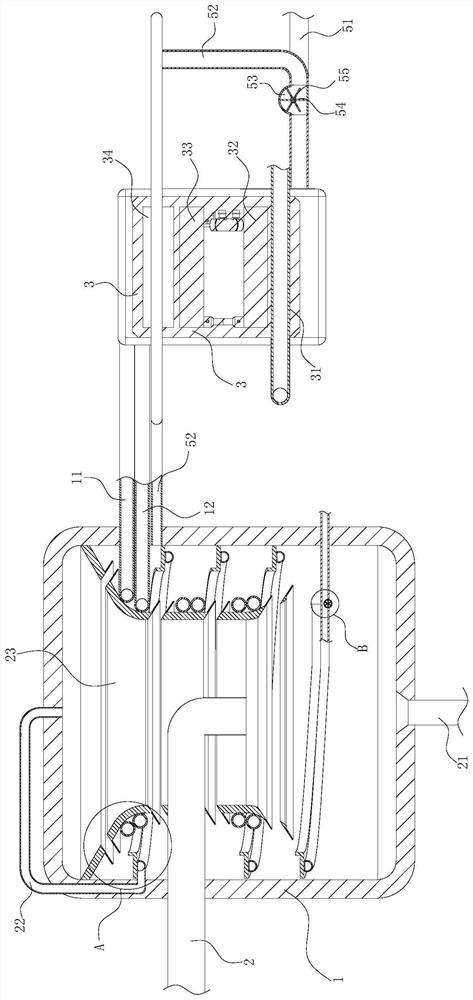

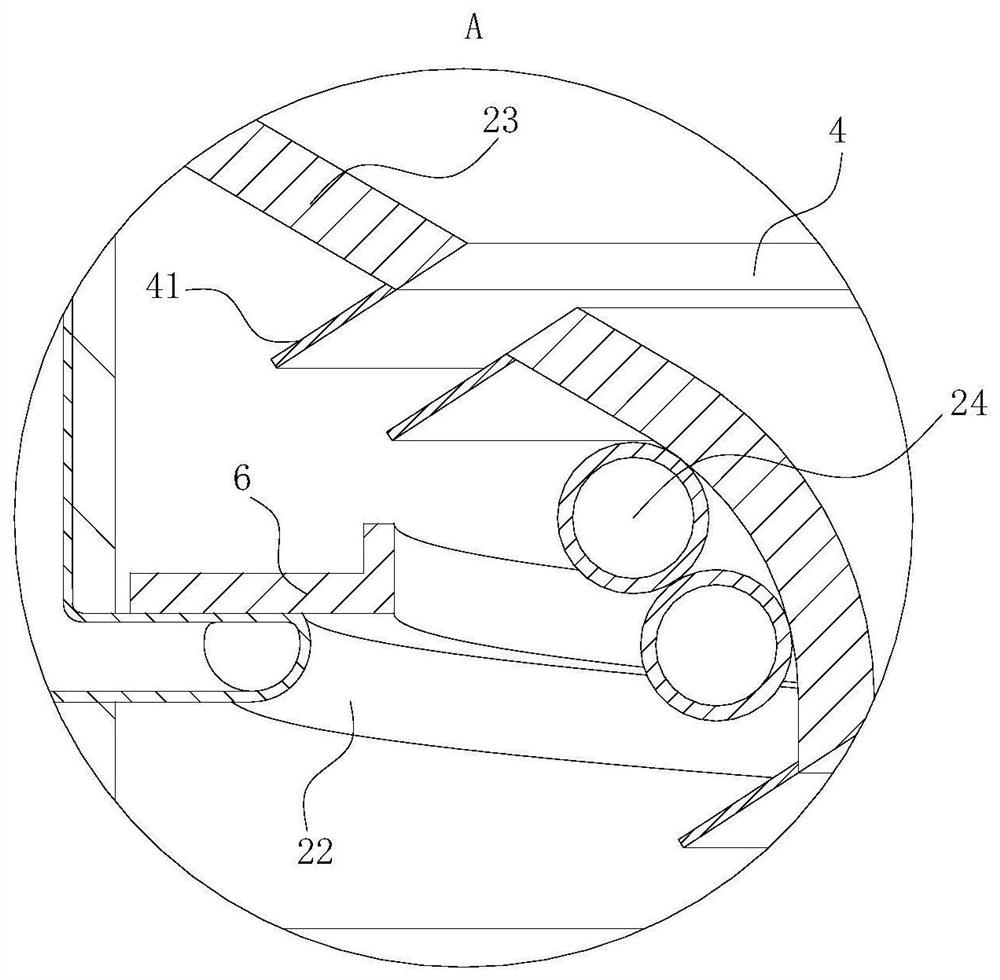

[0026] As an embodiment of the present invention, the water outlet pipe 12 is fixedly connected to the water storage tank 5 on the side close to the heat exchanger 3; Connected with a blowdown pipe 51; the blowdown pipe 51 is used to discharge boiler high-temperature waste water; the blowdown pipe 51 extends into the water storage tank 5; the blowdown pipe 51 is arranged in a spiral shape in the water storage tank 5; during work, the boiler The waste water itself contains high temperature, which causes a large amount of heat loss when it is discharged. At the same time, after the circulating water flows out of the condensation tank 1, the temperature is kept at 30-50°C all the year round. The sewage pipe 51 is extended to the water storage tank 5, and the circulating water and the boiler are used to The large temperature difference between the wastewater can effectively enhance the utilization efficiency of heat, and at the same time, the existence of the water storage tank 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com