Method for detecting effective gelatin concentration in copper electrolyte

A copper electrolyte and electrolyte technology, applied in the field of copper electrolysis, can solve the problems of systemic risk, long cycle, and difficulty in timely and accurate control of gelatin use, so as to reduce the interference of reduction peak current and reduce test interference. , the effect of high practical application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

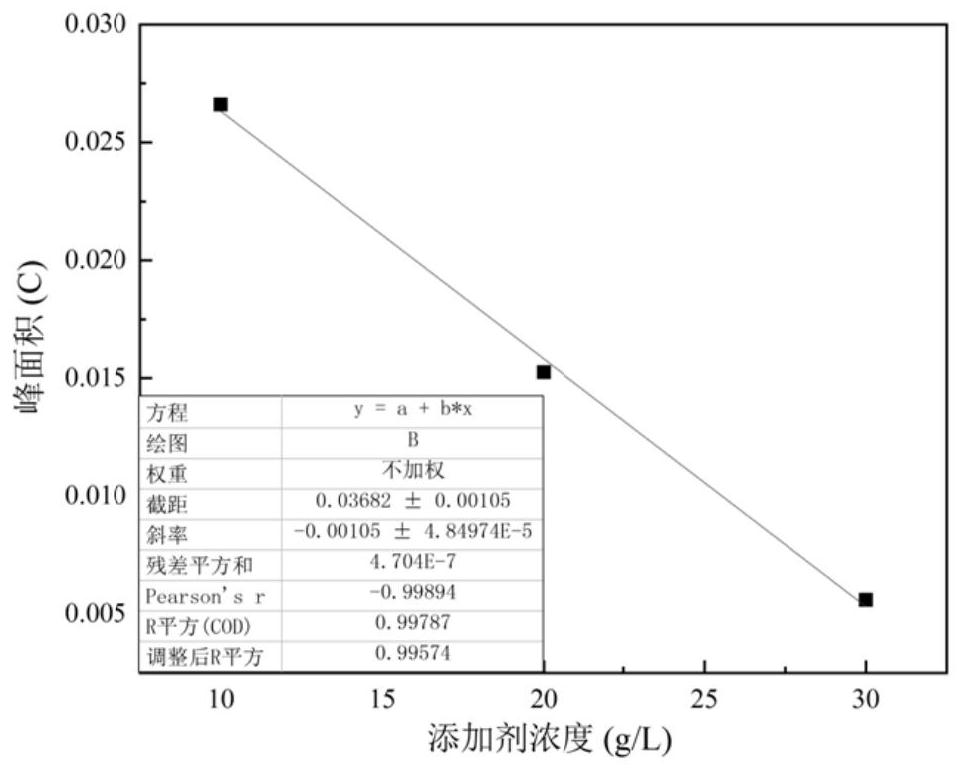

[0045] 1. In Cu 2+ Concentration 40g / L, sulfuric acid concentration 150g / L electrolyte, establish the standard curve of oxidation peak area and gelatin concentration

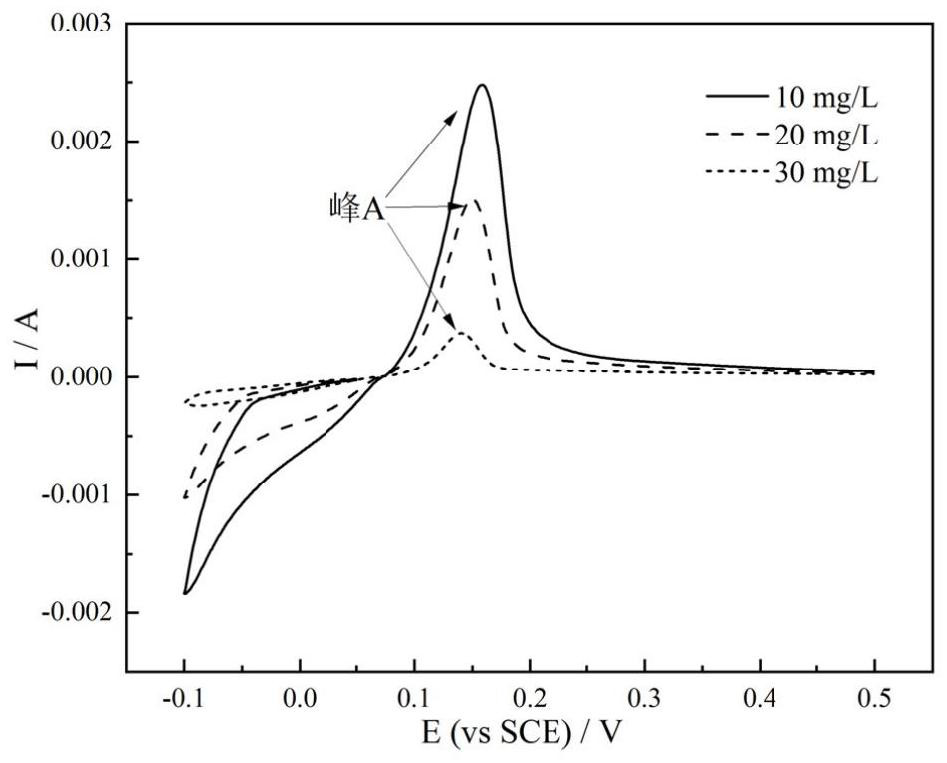

[0046] Select copper electrolyte solutions with gelatin concentrations of 10mg / L, 20mg / L, and 30mg / L respectively, and conduct the following tests on the electrolyte solutions with three gelatin concentrations in turn. The main salt composition and concentration in the copper electrolyte are: Cu 2+ Concentration 40g / L, sulfuric acid concentration 150g / L.

[0047] testing method:

[0048] (1) Liquid inlet: Add or pump the copper electrolyte into the test tank.

[0049] (2) Hydrodynamic voltammetry test: Insert three electrodes in the electrolyte to be tested in step (1), wherein the working electrode is a rotating disc electrode Pt, located in the middle of the test tank, and the saturated calomel electrode is a reference electrode , which is located 5mm above the working electrode, and the inert electrode is ...

Embodiment 2

[0057] 1. In Cu 2+ Concentration 60g / L, sulfuric acid concentration 200g / L electrolyte, establish the standard curve of oxidation peak area and gelatin concentration

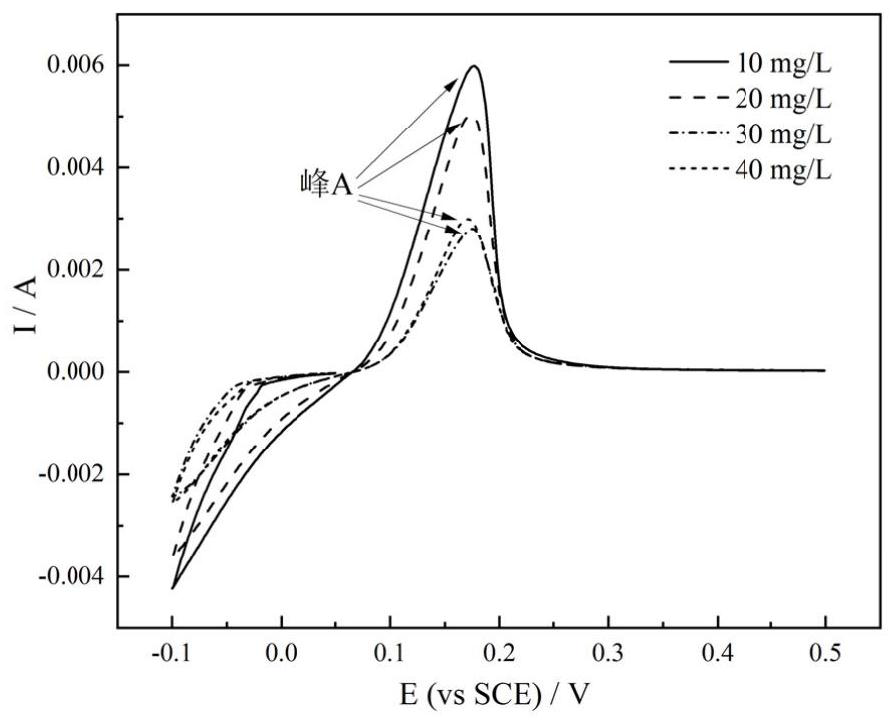

[0058] Select copper electrolyte solutions with gelatin concentrations of 10mg / L, 20mg / L, 30mg / L, and 40mg / L respectively, and perform the following tests on the electrolyte solutions with four gelatin concentrations in turn, where the main salt composition and concentration in the copper electrolyte are: Cu 2+ Concentration 60g / L, sulfuric acid concentration 200g / L.

[0059] testing method:

[0060] (1) Liquid inlet: Add or pump the copper electrolyte into the test tank.

[0061] (2) Hydrodynamic voltammetry test: Insert three electrodes in the electrolyte to be tested in step (1), wherein the working electrode is a rotating disc electrode Pt, located in the middle of the test tank, and the saturated mercurous sulfate electrode is a reference The electrode is located 3 mm above the working electrode, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotating speed | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com