Nickel-based alloy corrosion layer dynamic evolution analysis method based on cellular automaton

A cellular automaton, nickel-based alloy technology, applied in chemical process analysis/design, computer material science, computer-aided design, etc., can solve the problem of long-term corrosion behavior prediction, etc. High-quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

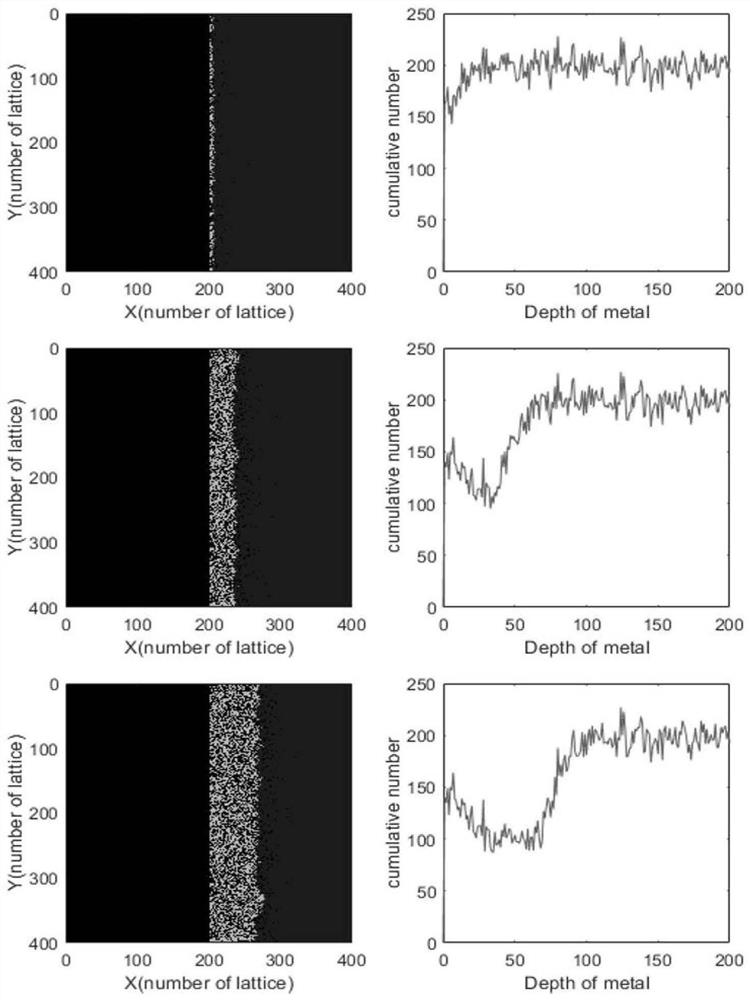

[0050] The present invention is a method for analyzing the dynamic evolution of nickel-based alloy corrosion layer based on cellular automata, which includes analysis of each cell and actual alloy samples in corrosion experiments. The method includes the following steps:

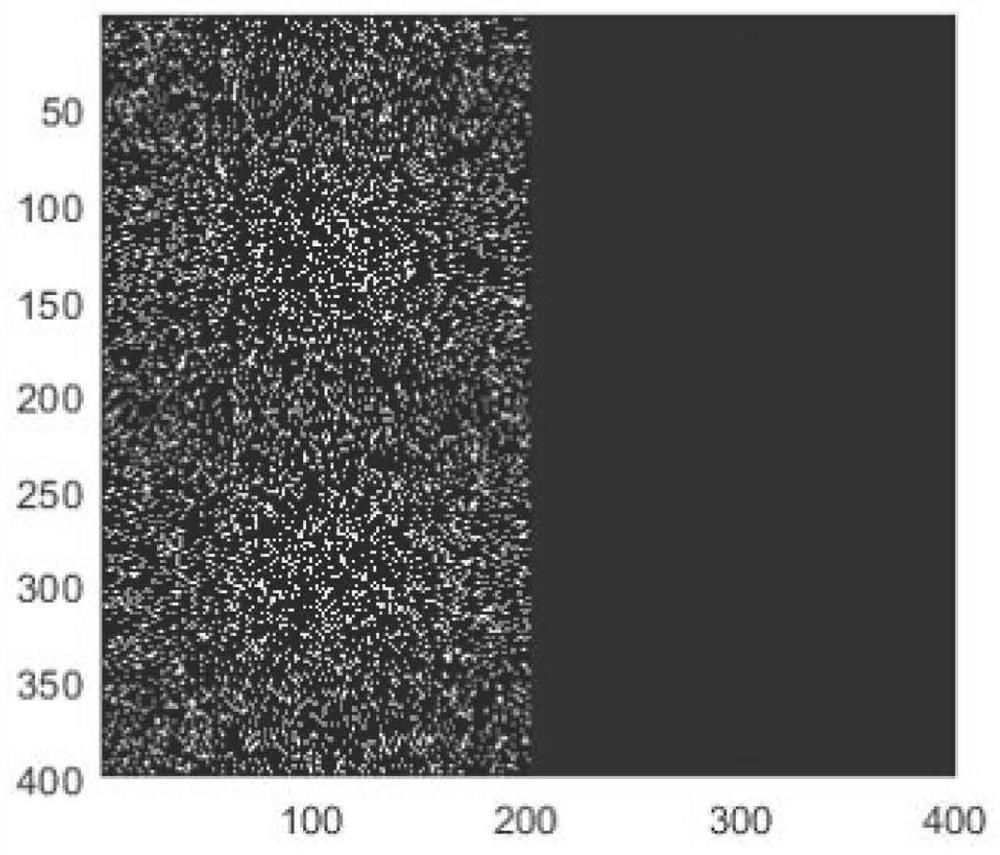

[0051] Step 1: Based on the actual shape of the alloy sample, select a corresponding coordinate system, define a two-dimensional cell space, select Margolus-type neighbors, and determine periodic boundary conditions;

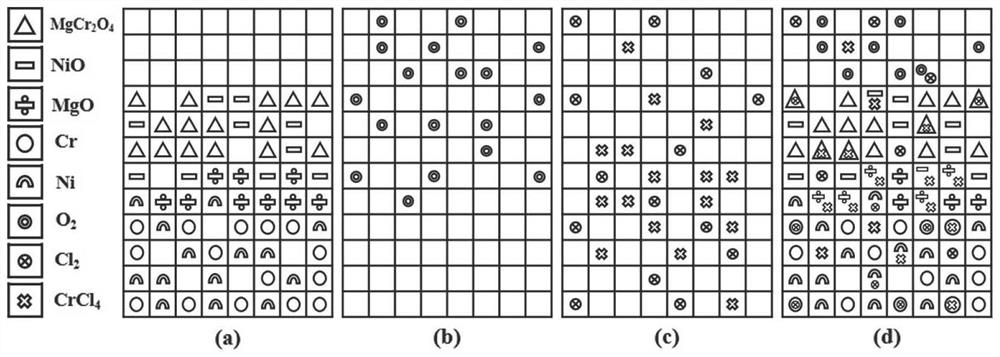

[0052] Step 2: according to the composition of the chloride molten salt and the alloy, define the properties of different lattice positions in the cell space;

[0053] Step 3: Define the evolution rules in the cellular automata space, realize the mutual conversion between cells in the cellular automata space, and convert the evolution rules into programming language through MATLAB software;

[0054] Step 4: Set an appropriate simulation time step, and use the two-dimensional cellular automata ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com