Yellow tea and preparation method thereof

A technology for dull yellow and green tea, applied in the field of yellow tea and its preparation, can solve the problems of different processing time, different transformation of fresh tea leaves, etc., and achieve the effects of easy operation, improving the color of tea soup, and reducing the content of tea polyphenols.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

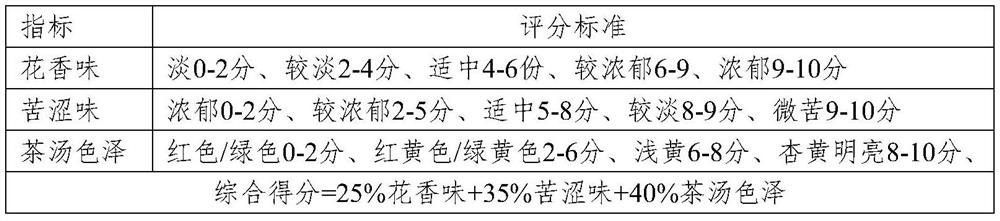

Examples

Embodiment 1

[0032] Yellow tea preparation method, comprises the following steps:

[0033] (1) pluck tea greens, spread them 2cm thick in a stall room (25-30° C.), and spread them until the water content of tea greens remains between 76-78%, so as to obtain once-spread green leaves;

[0034] (2) Send the once-spread green leaves into the green shaker for 1 minute, take them out, spread them in the spreading room (25-30°C) for 2 cm, and spread them until the water content is maintained at 55-60% , get the green leaves for the second time;

[0035] (3) The green leaves of the secondary spreading are fixed by microwave, and the green leaves are fixed at a temperature of 120° C. for 1 min, cooled to normal temperature, and the green leaves are obtained;

[0036] (4) Send the green leaves into the kneading machine for two kneading, and the first kneading is kneading at room temperature, the second kneading is kneading at 40°C, each kneading time is 1h, deblocking, and kneading leaves ; Descri...

Embodiment 2

[0056] Yellow tea preparation method, comprises the following steps:

[0057] (1) pluck tea greens, spread them 2cm thick in a stall room (25-30° C.), and spread them until the water content of tea greens remains between 76-78%, so as to obtain once-spread green leaves;

[0058] (2) Send green leaves once into the shaker for 5 minutes, take them out, spread them in the spreading room (25-30°C) for 2 cm, and spread them until the water content is maintained at 55-60% , get the green leaves for the second time;

[0059] (3) The green leaves of the secondary spreading are treated with microwave for 5 minutes at a temperature of 150° C., cooled to normal temperature, and the green leaves are obtained;

[0060] (4) Send the green leaves into the kneading machine for two kneading, and the first kneading is kneading at room temperature, the second kneading is kneading at 90°C, each kneading time is 1h, deblocking, and kneading leaves ; Described kneading is to adopt light pressure ...

Embodiment 3

[0065] Yellow tea preparation method, comprises the following steps:

[0066] (1) pluck tea greens, spread them 2cm thick in a stall room (25-30° C.), and spread them until the water content of tea greens remains between 76-78%, so as to obtain once-spread green leaves;

[0067] (2) Send green leaves once into the shaker for 3 minutes, take them out, spread them in the spreading room (25-30°C) for 2 cm, and spread them until the water content is maintained at 55-60% , get the green leaves for the second time;

[0068] (3) Microwave the green leaves for the second spreading, fix the green leaves at a temperature of 150° C. for 1 min, cool to normal temperature, and obtain the green leaves;

[0069] (4) Send the green leaves into the kneading machine for two kneading, and the first kneading is kneading at room temperature, the second kneading is kneading at 60°C, each kneading time is 1h, deblocking, and kneading leaves ; Described kneading is to adopt light pressure 12min, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com