Improved gel-state tobacco tar electronic cigarette and smoking method thereof

A gel state, electronic cigarette technology, applied in the field of electronic cigarettes, can solve problems such as inability to be atomized, interruption of suction, and power consumption of heating elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

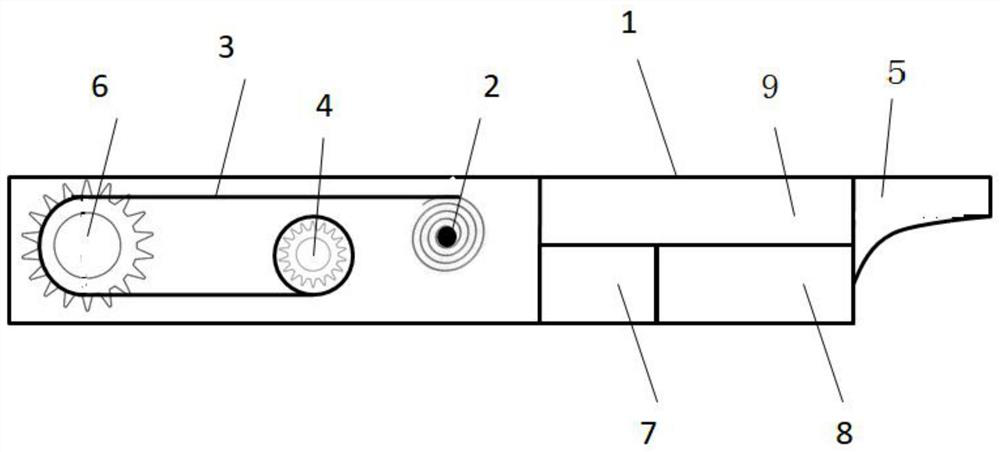

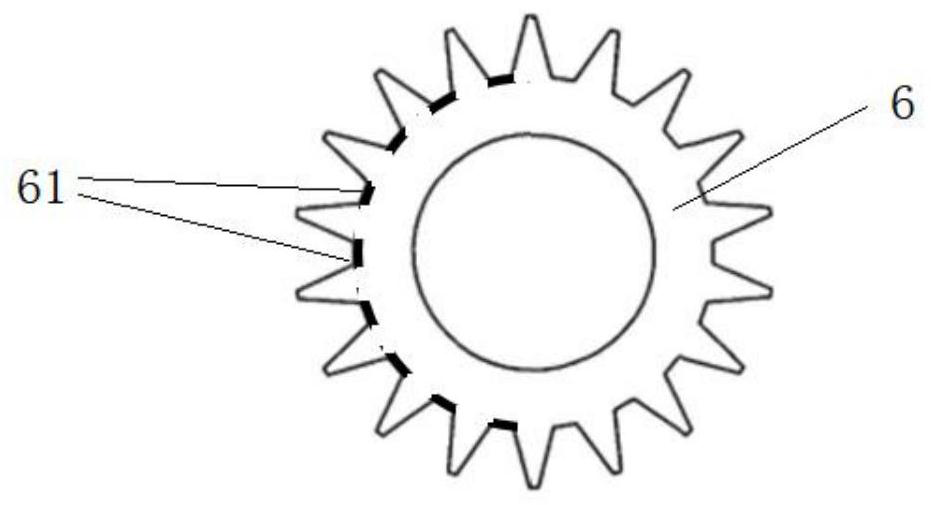

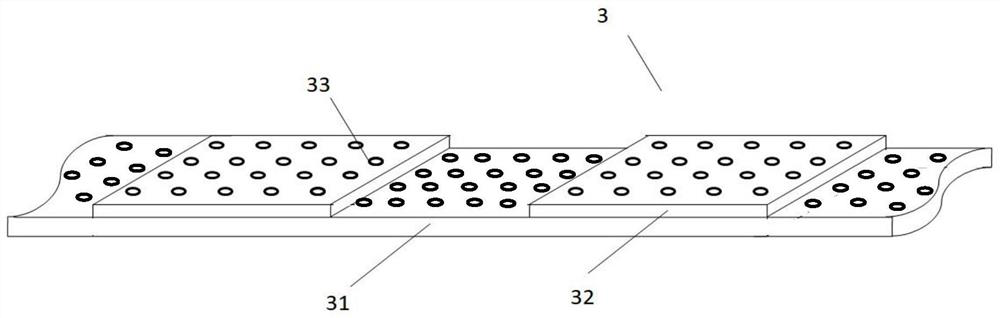

[0042] Use as the present invention figure 1 And the e-cigarette that can continuously supply gel-state e-liquid shown in the summary of the invention above. Wherein the driving reel 4 and the driven reel 6 both use gear-type reels, wherein the diameter of the driven reel is 6.0mm, and the peripheral surface of the driven reel 4 is coated with a resistance heating layer, and its corresponding central angle is 180°.

[0043] The basic formula of the liquid e-liquid is as follows: Glycerin is used as the main component of the aerosol, 1.5wt% of nicotine and 2.4wt% of mint essence are added to it, and flavoring agents and anti-sweetening agents can be added to the liquid e-liquid as required , food-grade preservatives, food-grade colorants and other conventional additives in the preparation of liquid e-liquid.

[0044] Add a gelling agent to the liquid e-liquid under the condition of heating to 80°C, and stir. The gelling agent is agarose, and the amount added is 9.5wt% of the l...

Embodiment 2

[0048] Use as the present invention figure 1 And the e-cigarette that can continuously supply gel-state e-liquid shown in the summary of the invention above. Wherein the driving reel 4 and the driven reel 6 both use gear-type reels, wherein the diameter of the driven reel is 6.0 mm, and the peripheral outer surface of the driven reel 4 is coated with a resistance heating layer, and its corresponding central angle is 120°.

[0049] The basic formula of the liquid e-liquid is as follows: Glycerin is used as the main component of the aerosol, 1.5wt% of nicotine and 2.4wt% of mint essence are added to it, and flavoring agents and anti-sweetening agents can be added to the liquid e-liquid as required , food-grade preservatives, food-grade colorants and other conventional additives in the preparation of liquid e-liquid.

[0050] Add a gelling agent to the liquid e-liquid under the condition of heating to 80°C, and stir. The gelling agent is gellan gum (also known as gellan gum), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com