Manufacturing device for denitration agent applied to industrial waste gas/flue gas

A technology for manufacturing equipment and industrial waste gas, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of poor denitrification quality and high cost of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

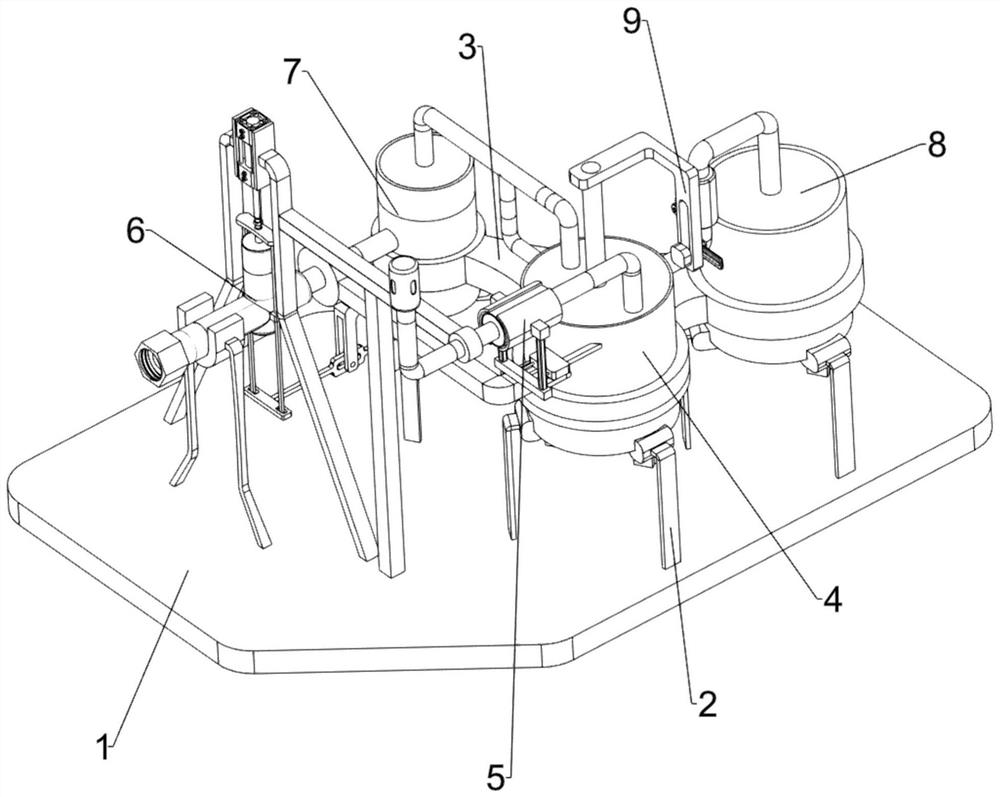

[0067] A denitration agent manufacturing device for industrial waste gas / flue gas, such as figure 1 As shown, it includes a bottom plate 1, a first frame 2, a connecting plate 3, a gas washing mechanism 4 and a gas drying mechanism 5. There are three sets of first frames 2 on the upper right of the bottom plate 1, and each group has three first frames 2. The connecting plate 3 is provided in the upper middle of the bottom plate 1, and the top of a group of first racks 2 on the left front side is provided with a gas washing mechanism 4, which is connected with the connecting plate 3, and a gas drying mechanism is installed on the left side of the bottom plate 1 5. The gas drying mechanism 5 is connected to the gas scrubbing mechanism 4 .

[0068]When the factory reduces the nitrate content in the exhausted flue gas, the required cost is relatively high. The present invention helps people reduce the cost of processing the flue gas. First, ammonia water is added in the gas scrubb...

Embodiment 2

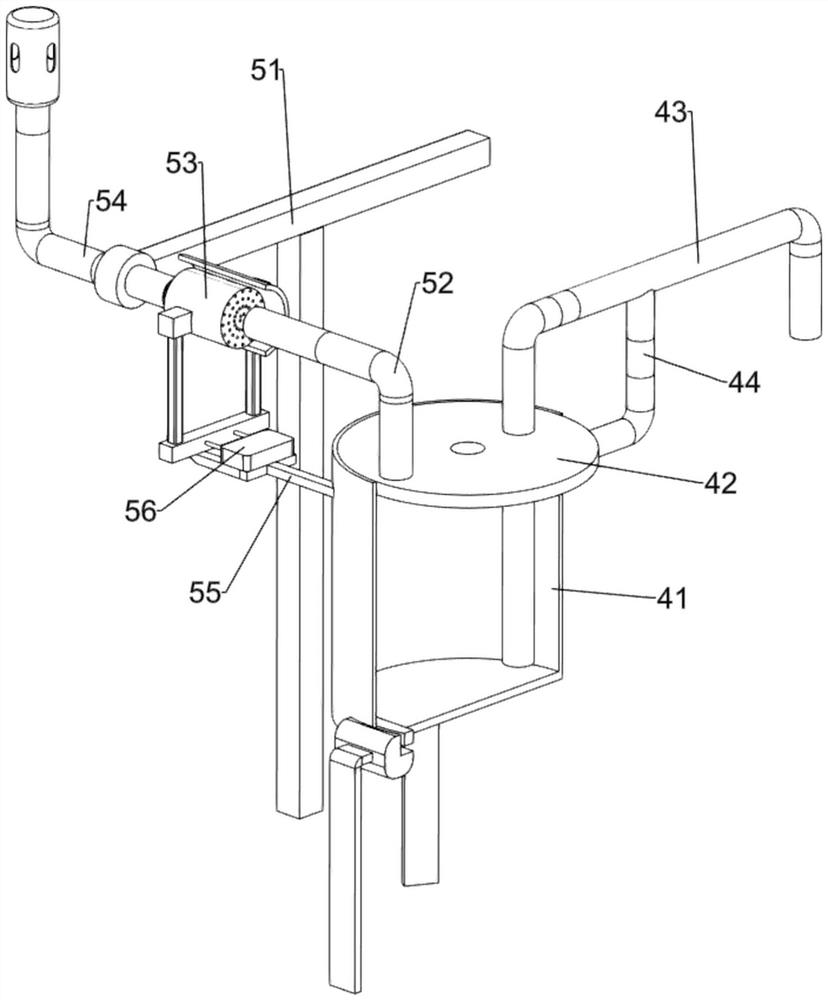

[0070] On the basis of Example 1, such as figure 2 As shown, the scrubbing mechanism 4 includes a washing tub wall 41, a first top cover 42, a first air pipe 43 and a backflow pipe 44, and the top of a group of first racks 2 on the left front side is provided with a washing tub wall 41, and the washing tub wall 41 is connected with the connecting plate 3, the top of the washing bucket wall 41 is provided with a first top cover 42, the rear of the first top cover 42 is provided with a first air pipe 43, and the back side of the washing bucket wall 41 is provided with a backflow pipe 44, and the backflow pipe 44 It is connected with the first air pipe 43 .

[0071] First, add ammonia water in the washing bucket wall 41, so that the liquid level of the ammonia water is not over the first air pipe 43, the first top cover 42 prevents the ammonia water from evaporating, and the smoke is discharged into the washing bucket wall 41 through the first air pipe 43, so that the smoke The...

Embodiment 3

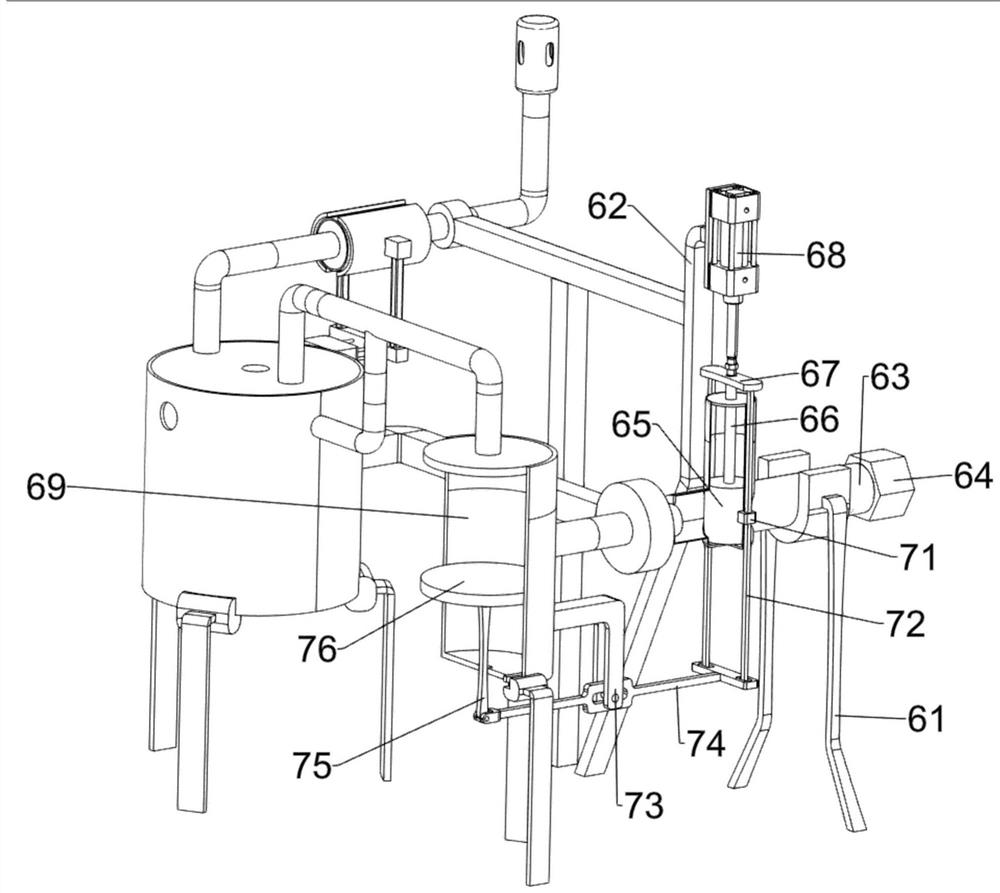

[0075] On the basis of Example 2, such as figure 1 , image 3 and Figure 4 As shown, an air intake mechanism 6 is also included. An air intake mechanism 6 is provided on the upper left rear side of the bottom plate 1. The air intake mechanism 6 is connected with the first frame 2 and the connecting plate 3. The air intake mechanism 6 includes an air injection barrel. 69. The second frame 61, the third frame 62, the air duct 63, the butt nut 64, the first piston 65, the first pull rod 66, the connection block 67 and the cylinder 68, a group of the first frame 2 on the left rear side An air injection barrel 69 is provided on the top, and the air injection barrel 69 is connected with the first air pipe 43 and the connecting plate 3. The second rack 61 is provided on the left rear part of the bottom plate 1, and two second racks are provided on the left rear part of the bottom plate 1. Three frames 62, the third frame 62 on the front side is connected with the first connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com