Multi-target rice milling unit scheduling optimization system based on ACO-BP

A multi-target, rice mill technology, applied in the direction of comprehensive factory control, instrumentation, grain hulling, etc., can solve the problems of high production energy consumption, low processing efficiency, and different quality of polished rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

[0047] 1. Control system network structure design

[0048] 1. System communication structure

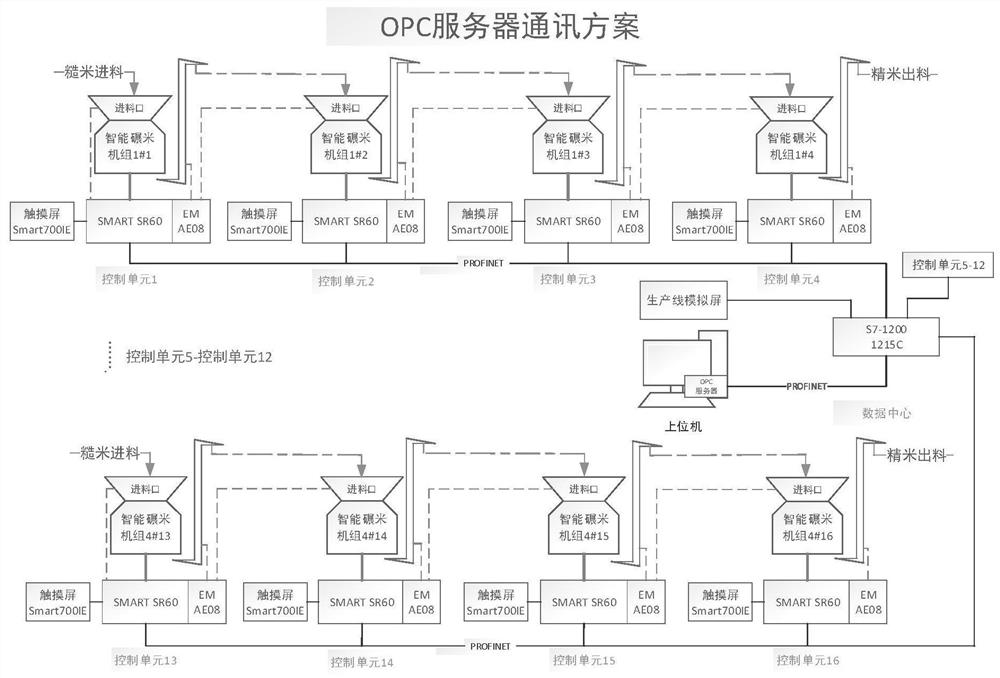

[0049] The dispatching and control system of intelligent rice milling unit consists of multiple groups of [intelligent rice milling unit], [data center] and [SCADA system]. The system adopts a centralized and distributed structure. The [intelligent rice milling unit] adopts a local controller, the [data center] adopts a central controller, and the controller, data center and SCADA system adopt industrial Ethernet communication. Each [rice milling unit] It can read and write the data of [data center] in real time, establish a real-time data buffer area of each unit on [data center], analyze and filter data through the SCADA system, exchange information between the OPC server and the SCADA system, and establish an intelligent rice milling unit in the data center The database ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com