Welding robot control system based on big data

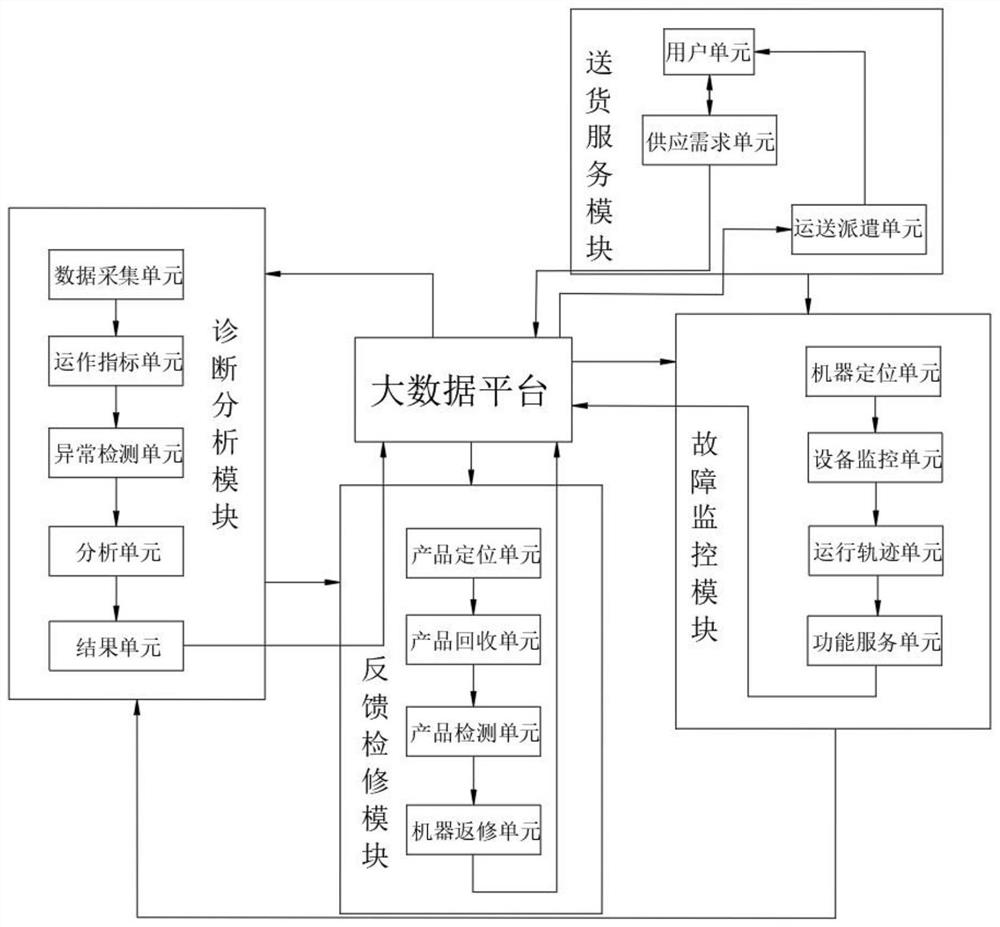

A welding robot and control system technology, applied in welding equipment, auxiliary welding equipment, program-controlled manipulators, etc., can solve problems such as waste of human resources, delay in detection of faults, and unavoidable mechanical failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Suppose it is necessary to use the abnormal detection model in the abnormal detection unit to check the welding speed of the welding robot, the maximum distance L between the center of the circle O and the peripheral points max is 50.21, the neighbor point P 1 The coordinates in the anomaly detection model are (30.31, 39.05), and the neighbor point P 2 The coordinates in the anomaly detection model are (40.89, 29.87), using the Euclidean distance formula to calculate the circle point O and the neighbor point P 1 and P 2 the distance:

[0070]

[0071]

[0072] Because L(P 1 , O)max , then P 1 Belongs to this data group, which is the normal welding speed, because L(P 1 ,0)>L max , then P 1 It belongs to abnormal data. There is a problem with the welding speed of the welding robot, which needs to be analyzed and repaired in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com