3D printing system

A 3D printing and wavelength conversion unit technology, applied in the field of 3D printing systems, can solve the problems of low UV light output power, aging, and limited printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

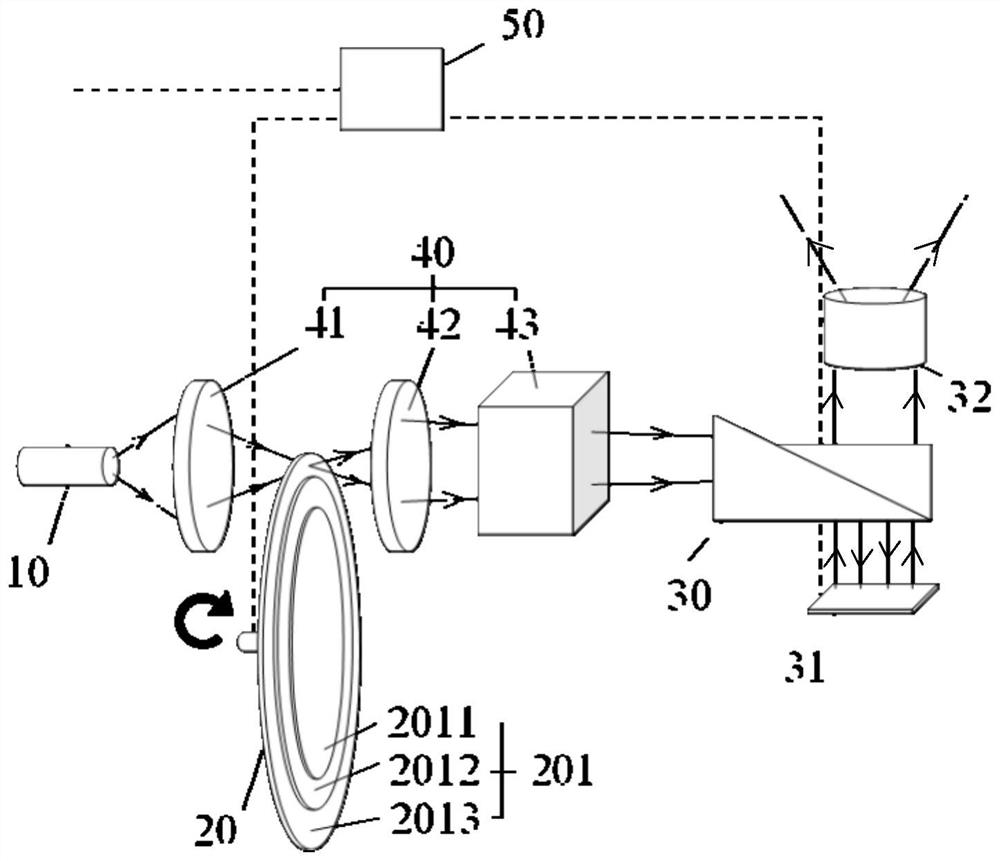

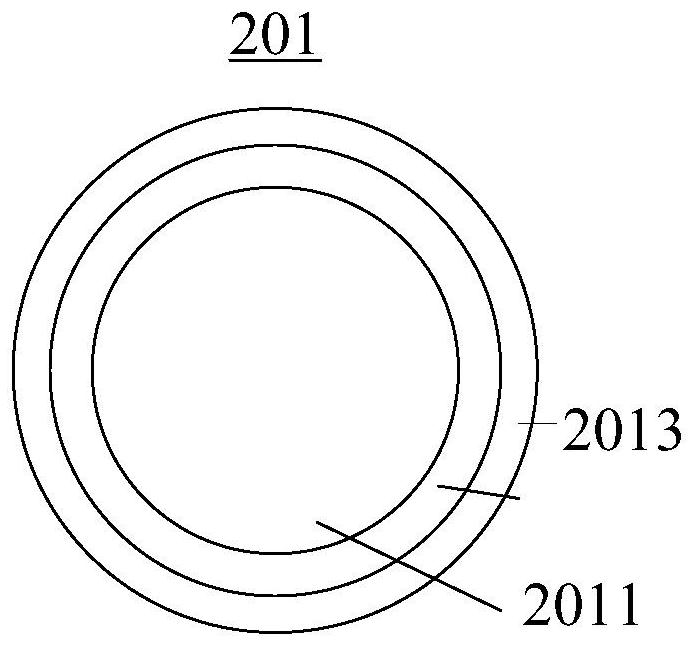

[0052] In this embodiment, the light emitting unit 10 of the 3D printing system is a blue semiconductor laser, the wavelength conversion unit 20 includes a control unit, and a fluorescent pink wheel driven by the control unit, the fluorescent pink wheel includes The powder-free ring area 2011, the green phosphor ring area 2012 and the red phosphor ring area 2013 are set in sequence outside.

[0053] The above-mentioned 3D printing system is loaded on the 3D printing equipment, and blue light curing resin is added in the 3D printing equipment. Set the optical power density of the pattern directed to the surface of the photocurable material to be cured to 10mW / cm 2 , the printing layer thickness is 0.05mm, and the single layer curing time is 2s.

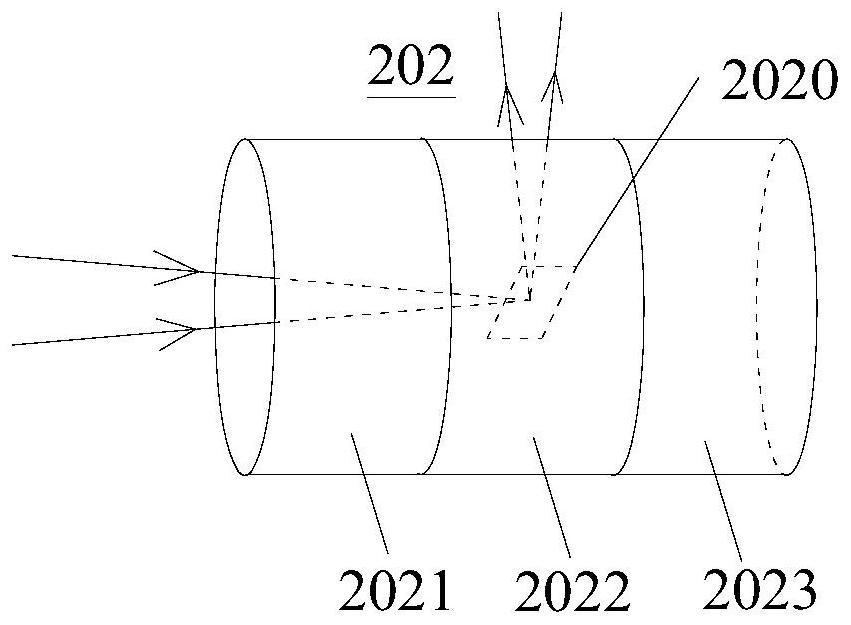

[0054] Printing starts, the blue semiconductor laser emits 445nm blue excitation light after the control unit 40 applies an external current, and then the excitation light is guided to the powder-free ring area 2011 of the fluorescent...

Embodiment 2

[0056]In this embodiment, the light emitting unit 10 of the 3D printing system is a blue semiconductor laser, the wavelength conversion unit 20 includes a control unit, and a fluorescent pink wheel driven by the control unit, the fluorescent pink wheel includes The powder-free ring area 2011, the green phosphor ring area 2012 and the red phosphor ring area 2013 are set in sequence outside.

[0057] Load the above 3D printing system on a 3D printing device, and add green light-curable resin to the 3D printing device. Compared with Embodiment 1, the type of photocurable resin in this embodiment is changed, and the control unit needs to adjust the working parameters of the 3D printing system before 3D printing can be performed. Specifically, the optical power density of the pattern to be guided to the surface of the photocurable material to be cured ranged from 10mW / cm 2 Adjust to 15mW / cm 2 , and move the position of the fluorescent pink wheel 201 , so that the excitation light...

Embodiment 3

[0060] In this embodiment, the light emitting unit 10 of the 3D printing system is a blue semiconductor laser, the wavelength conversion unit 20 includes a control unit, and a fluorescent pink wheel driven by the control unit, the fluorescent pink wheel includes The powder-free ring area 2011, the green phosphor ring area 2012 and the red phosphor ring area 2013 are set in sequence outside.

[0061] Load the above 3D printing system on a 3D printing device, and add red light-curable resin to the 3D printing device. Compared with Embodiment 1, the type of photocurable resin in this embodiment is changed, and the control unit needs to adjust the working parameters of the 3D printing system before 3D printing can be performed. Specifically, the optical power density of the pattern to be guided to the surface of the photocurable material to be cured ranged from 10mW / cm 2 Adjust to 30mW / cm 2 , adjust the curing time of the single layer from 2s to 3s, and move the position of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical power density | aaaaa | aaaaa |

| Optical power density | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap