High-purity superfine silicon dioxide for honeycomb ceramic carrier and preparation method of high-purity superfine silicon dioxide

A technology of honeycomb ceramic carrier and ultra-fine silica, applied in the direction of silica, silicon oxide, etc., can solve the problems that cannot reach 99.9%, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

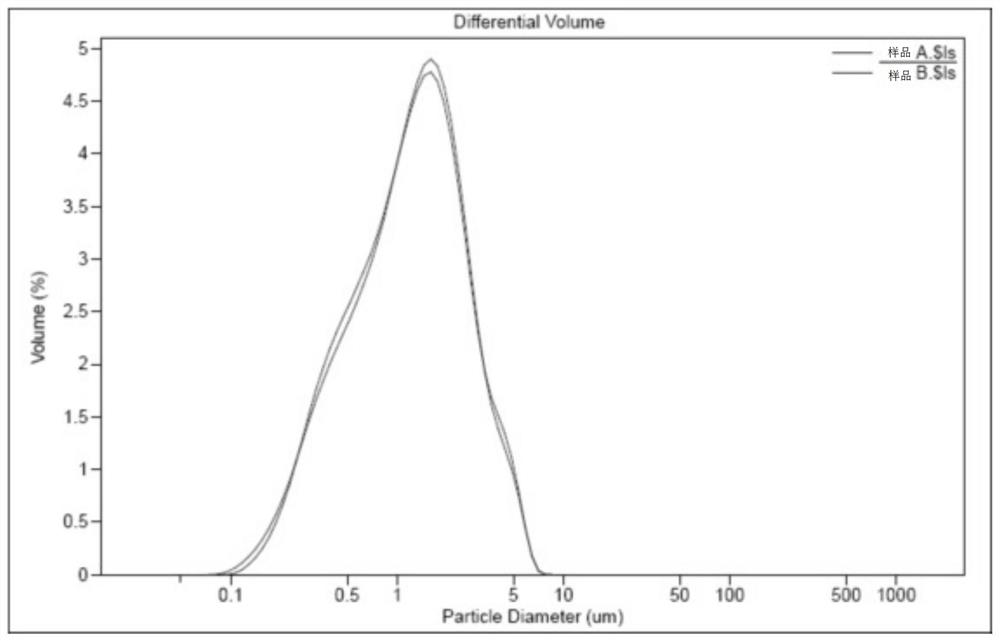

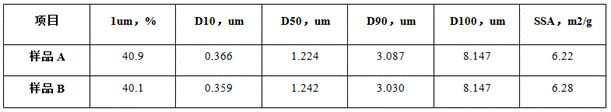

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of preparation method of high-purity ultrafine silicon dioxide micropowder for honeycomb ceramic carrier, this method comprises following specific steps,

[0027] 4.1. Material selection:

[0028] Choose SiO2 2 Content: ≥99.7%, magnetic impurity content: ≤15ppm high-purity crystalline block, while producing D50: 8-10μm high-purity silica powder products and high-purity ultra-fine silica powder products that meet the requirements, that is, meet the national VI Emission standards, and the solid content of the slurry after production is greatly reduced, which is easy to handle.

[0029] 4.2. Preparation process:

[0030] (1) SiO 2 The high-purity crystalline blocks with a content of more than 99.7% are crushed and screened with a 4-24 mesh vibrating sieve, transported by a belt conveyor, and the crystalline sand is removed by a 6-layer * 9-section magnetic rod (10000Gs) iron remover Iron, to produce specific high-purity crystalline sand raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com