Nickel-doped brownmillerite type oxygen carrier as well as preparation method and application thereof

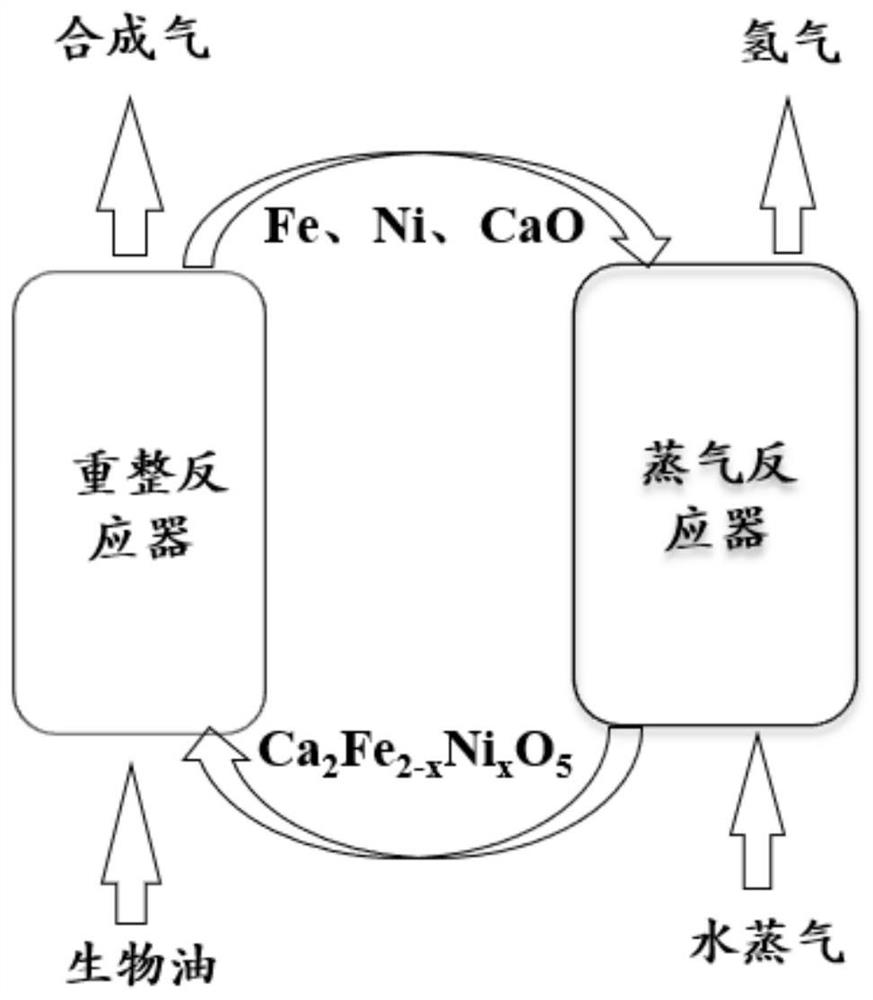

A technology of oxygen carrier and andorite, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of low activity of oxygen carrier, low carbon conversion efficiency, poor stability, etc., achieve high activity and improve hydrogen production capacity , to promote the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

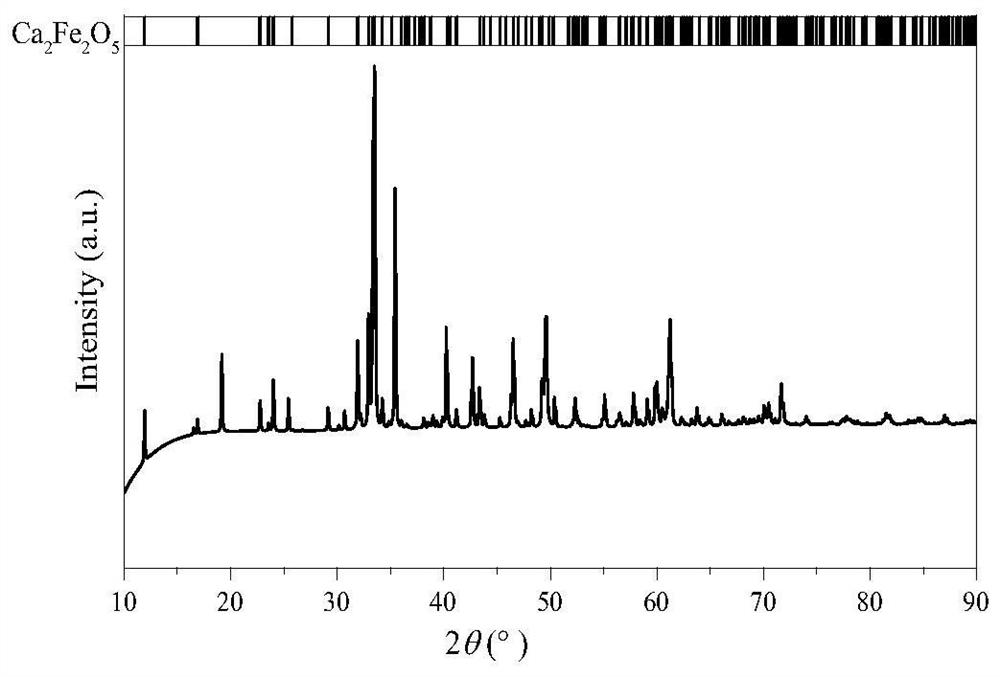

[0034] A nickel-doped anderite-type oxygen carrier prepared by the following method:

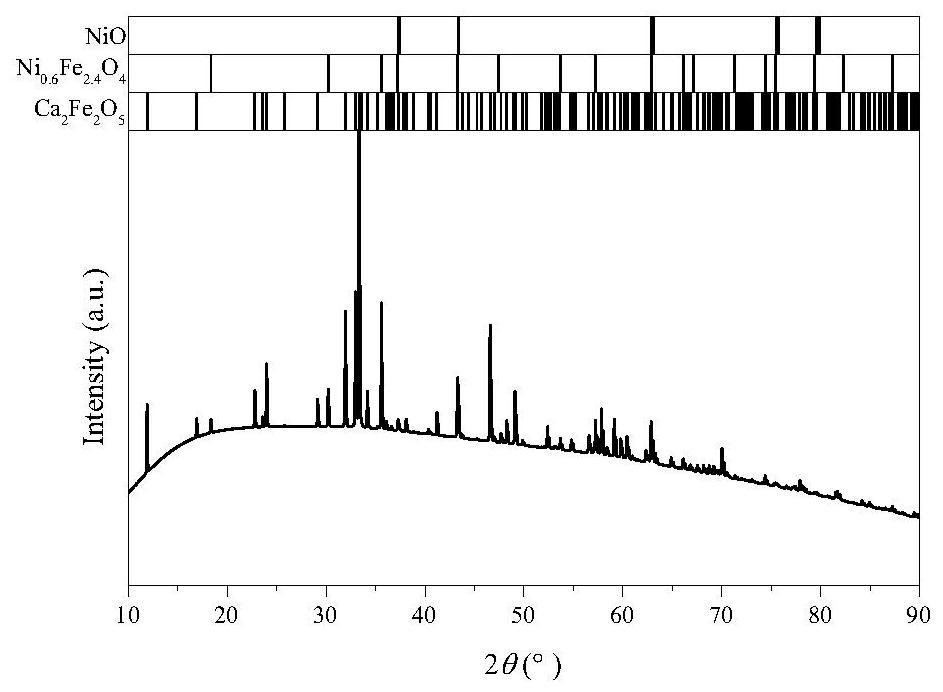

[0035] Weigh 0.20mol of calcium nitrate Ca(NO 3 ) 2 , 0.175mol of iron nitrate Fe(NO 3 ) 3 , 0.025mol nickel nitrate Ni(NO 3 ) 2 , Put 1.20mol of citric acid in a beaker, add 1000ml of deionized water into the beaker, transfer the beaker to a 95°C oil bath, heat and stir for 8h to obtain the precursor. Dry the precursor in a constant temperature drying oven at 105°C for 12 hours, then put it into a muffle furnace and calcinate it at 1000°C for 10 hours to obtain nickel-doped willorite-type oxygen carrier, denoted as Ca 2 Fe 1.75 Ni 0.25 o 5 oxygen carrier.

Embodiment 2

[0037]A nickel-doped anderite-type oxygen carrier prepared by the following method:

[0038] Weigh 0.20mol of calcium nitrate Ca(NO 3 ) 2 , 0.150mol of iron nitrate Fe(NO 3 ) 3 , 0.050mol nickel nitrate Ni(NO 3 ) 2 , Put 1.20mol of citric acid in a beaker, add 1000ml of deionized water into the beaker, transfer the beaker to a 95°C oil bath, heat and stir for 8h to obtain the precursor. Dry the precursor in a constant temperature drying oven at 105°C for 12 hours, then put it into a muffle furnace and calcinate it at 1000°C for 10 hours to obtain nickel-doped willorite-type oxygen carrier, denoted as Ca 2 Fe 1.50 Ni 0.50 o 5 oxygen carrier.

Embodiment 3

[0040] A nickel-doped anderite-type oxygen carrier prepared by the following method:

[0041] Weigh 0.2mol of calcium nitrate Ca(NO 3 ) 2 , 0.125mol of iron nitrate Fe(NO 3 ) 3 , 0.075mol nickel nitrate Ni(NO 3 ) 2 , Put 1.20mol of citric acid in a beaker, add 1000ml of deionized water into the beaker, transfer the beaker to a 95°C oil bath, heat and stir for 8h to obtain the precursor. Dry the precursor in a constant temperature drying oven at 105°C for 12 hours, then put it into a muffle furnace and calcinate it at 1000°C for 10 hours to obtain nickel-doped willorite-type oxygen carrier, denoted as Ca 2 Fe 1.25 Ni 0.75 o 5 oxygen carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com