Midostaurin new crystal forms and preparation method and application thereof

A technology of midostaurin and crystal form, which is applied in the field of chemical pharmacy and can solve problems such as difficulty in promotion, difficulty in spontaneous crystallization, and difficulty in realizing industrialized operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1 Preparation of Midostaurin Form A

[0087] Dissolve 1.0 g of midostaurin crude product in 4 mL of benzyl alcohol, heat up to 80 ° C, dissolve, filter, add 50 ml of poor solvent (volume ratio of ethanol to water: 1:1) while stirring, finish adding within 10 min, and then cool down to Stir and crystallize at 0°C for 16 hours, filter, and vacuum-dry at 40°C to obtain 0.95 g of crystals, which are easy to filter and have a purity of 99.72% by HPLC.

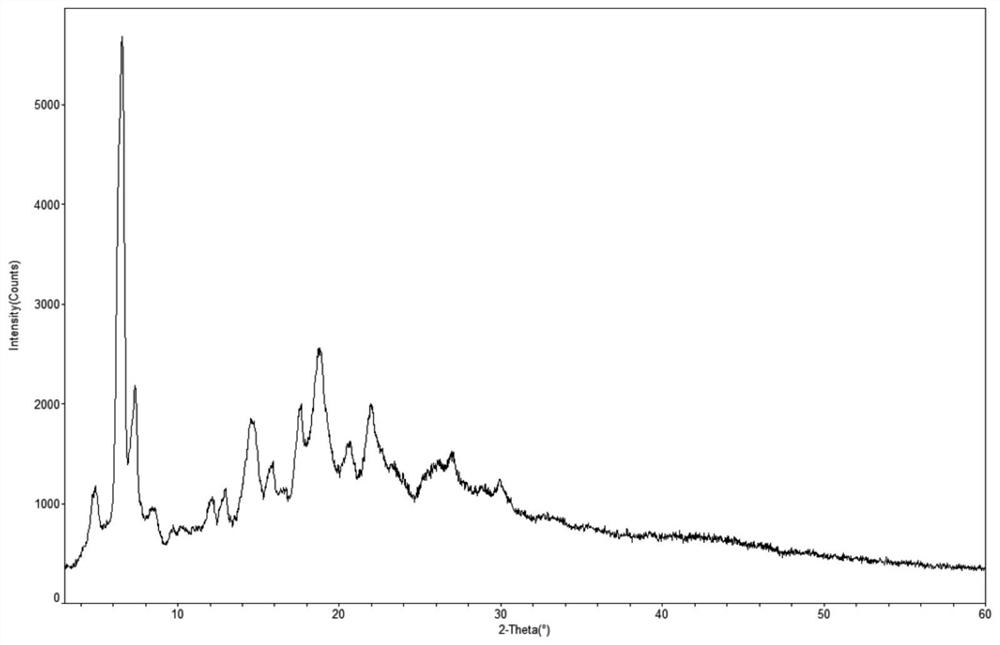

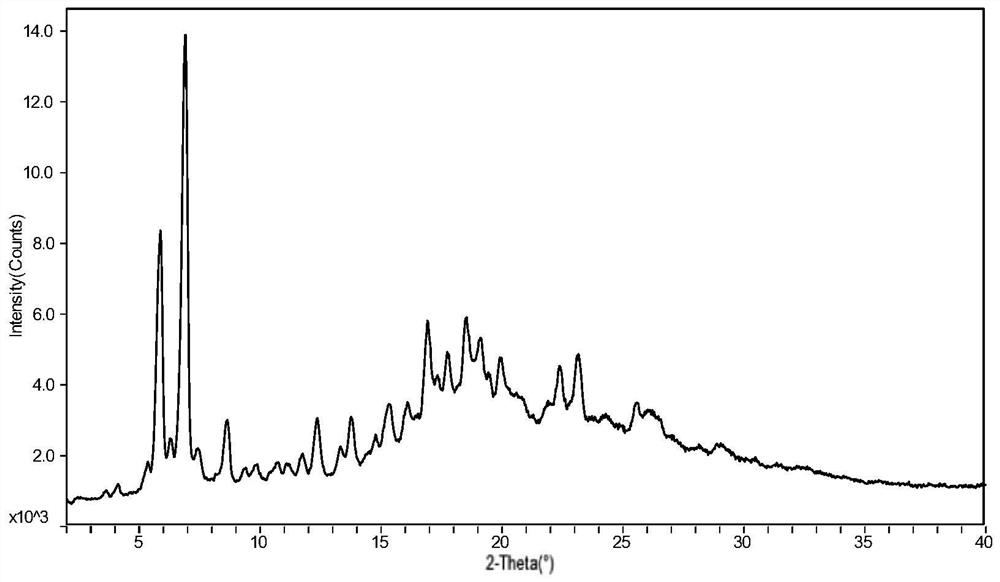

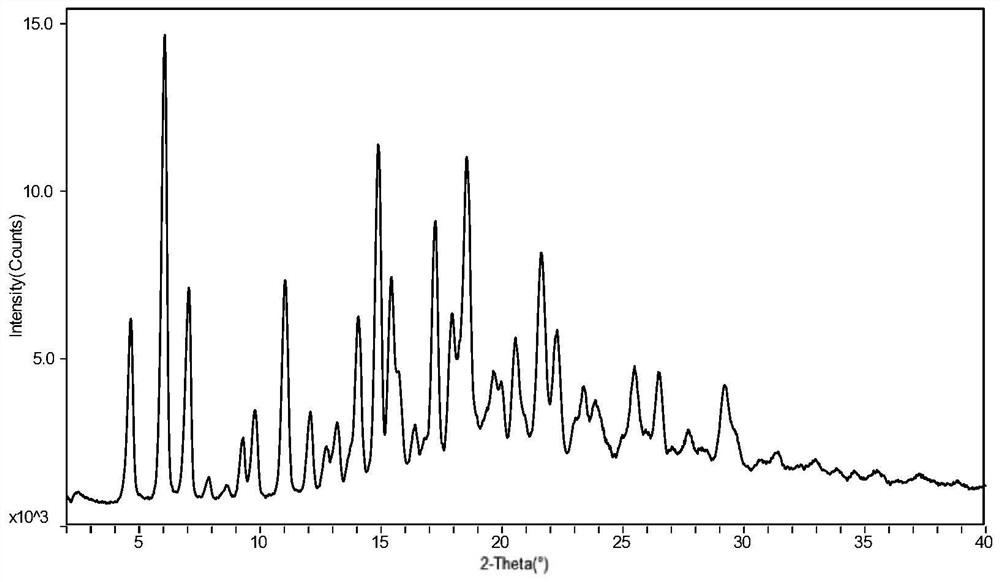

[0088] The X-ray powder diffraction pattern of this crystal is detailed in figure 1 , see the TGA spectrum figure 2 , which is named midostaurin crystal form A in the present invention.

Embodiment 2

[0089] Example 2 Preparation of Midostaurin Form A

[0090] Dissolve 0.5 g of midostaurin crude product in 1 mL of benzyl alcohol, heat up to 80 ° C, dissolve, filter, add 6 ml of poor solvent (volume ratio of ethanol to water: 1:1) while stirring, finish adding within 5 min, and then cool down to Stir and crystallize at 0°C for 48 hours, filter, and vacuum-dry at 40°C to obtain 0.47 g of crystals, which are easy to filter and have a purity of 99.71% by HPLC. After measuring the X-ray powder diffraction pattern (XRD), it was confirmed to be midostaurin crystal form A.

Embodiment 3

[0091] Example 3 Preparation of Midostaurin Form A

[0092] Dissolve 0.5 g of midostaurin crude product in 5 mL of benzyl alcohol, heat up to 40 ° C, dissolve, filter, add 250 ml of poor solvent (volume ratio of ethanol to water: 1:1) while stirring, finish adding within 30 min, and then cool down to Stir and crystallize at 20°C for 24 hours, filter, and vacuum-dry at 40°C to obtain 0.47 g of crystals, which are easy to filter and have a purity of 99.71% by HPLC. After measuring the X-ray powder diffraction pattern (XRD), it was confirmed to be midostaurin crystal form A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com