A kind of multifunctional cotton fabric with reproducible antibacterial performance and its preparation method

A dual-function, antibacterial agent technology, applied in plant fibers, wear-resistant fibers, textiles, and papermaking, can solve the problems of inability to exert antibacterial and reproducible halide amines, and unknown antibacterial performance, so as to achieve repeated and efficient utilization, slow down Bacterial growth rate and the effect of increasing the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

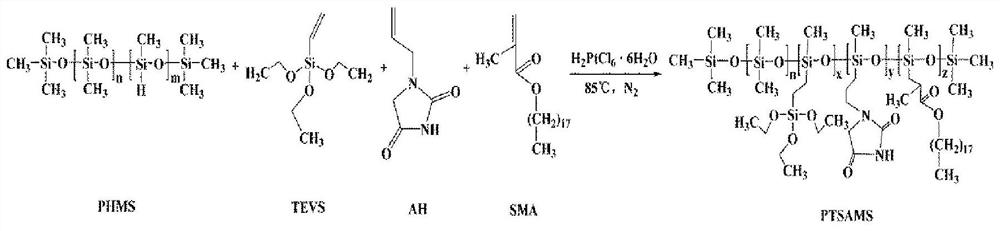

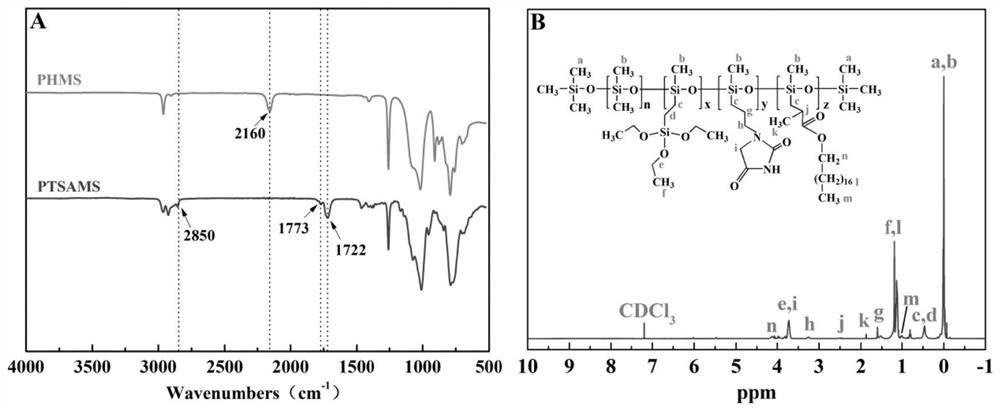

[0051] Take 10g of PHMS (dimethylmethylhydrogen (siloxane and polysiloxane), the relative molecular mass is 2000g / mol, and the contained CH 3 OSiH repeating unit accounted for 30% of the total Si-O repeating unit quantity) into a 100mL three-necked flask, and then added 40g isopropanol, 4.56g TEVS (vinyltriethoxysilane), 1.34g AH (1-allyl Hydantoin) and 4.88g SMA (stearyl methacrylate) (the molar ratio of alkenyl monomers is 5:2:3), and the above mixture was blown with nitrogen at room temperature for 10 minutes to remove the air in the bottle. Then add a certain amount of chloroplatinic acid hexahydrate catalyst (the content of Pt is 50ppm) in the bottle, under nitrogen protection, react at 85 ℃ of conditions, adopt infrared spectrum monitoring reaction progress, until Si-H characteristic peak disappears in the infrared spectrum, Total reaction 6h. Finally decompression distillation removes solvent and unnecessary TEVS and leaves standstill, after superfluous AH and SMA soli...

Embodiment 2

[0064] The multifunctional cotton fabric is prepared with reference to the method in Example 1, the difference is that the ethylenic monomers added in the adjustment Example 1 are respectively 5.47g TEVS (vinyltriethoxysilane), 1.34g AH (1-allyl Hydantoin) and 3.25gSMA (stearyl methacrylate) (alkenyl monomer molar ratio is 6:2:2), other conditions or parameters are consistent with Example 1.

[0065] The prepared cotton fabric also has excellent antibacterial properties, hydrophobic properties and anti-wrinkle properties. In addition, the contact angle of the finished cotton fabric after chlorination is significantly improved compared with that before chlorination. In addition, the relationship between the chlorine content and the contact angle of the cotton fabric under water washing, rubbing, and ultraviolet light is also consistent with that in Example 1. Therefore, the finishing agent prepared in this example can also achieve the effects described in Example 1, that is, i...

Embodiment 3

[0067] Take 10g of PHMS (dimethylmethylhydrogen (siloxane and polysiloxane), the relative molecular mass is 8000g / mol, and the contained CH 3 The OSiH repeating unit accounts for 20% of the entire Si-O repeating unit) into a 100mL three-necked flask, and then 40g of isopropanol, 2.22g of vinyltrimethoxysilane, 1.01g of 5,5-dimethyl-3-( 1-allyl)hydantoin and 2.27g (1-octadecene) (the molar ratio of alkenyl monomers is 5:2:3), and the above mixture was blown with nitrogen at room temperature for 10 minutes to remove the air in the bottle. Then add a certain amount of palladium catalyst (the content of palladium is 80ppm) in the bottle, react at 90°C for 8h under the protection of nitrogen, and finally remove the solvent and excess vinyltrimethoxysilane by distillation under reduced pressure and let it stand until the excess After the 5,5-dimethyl-3-(1-allyl)hydantoin and 1-alkenyl octadecane solids are precipitated, the upper transparent viscous liquid is taken to prepare a mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com