Drilling tool with variable stirring angle

A drilling tool and angle technology, which is used in construction, sheet pile wall, infrastructure engineering, etc., can solve the problems of large slurry spray resistance, insufficient cement slurry, difficult cement slurry and soil mixing evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

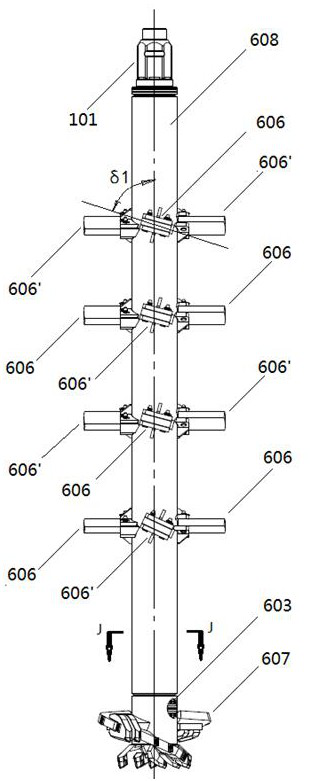

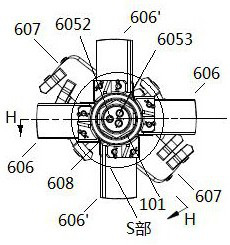

[0028] A drilling tool with a variable stirring angle, including: a drilling tool body 608 with a male joint 101, a lower spray port 603, a second built-in pipeline 605 and an air injection port 609, multiple sets of first stirring blades 606 and cutting blades 607, of which:

[0029] The male joint 101 includes a male fixing plate 1011 located on its upper end surface and having a male plate through hole 1012;

[0030] The second built-in pipeline 605 includes a third slurry pipe 6052, a second air pipe 6053 and a plurality of second pipeline frames 6054;

[0031] Each set of first stirring blades 606 includes a first blade 6061 and a first blade seat 6062;

[0032] It is characterized by:

[0033] There are three through holes 1012 in the male fixing plate 1011 of the male joint 101 of the drill pipe body 608, which are arranged in an equilateral triangle symmetrical manner in the radial direction of the male fixing plate 1011;

[0034] The lower grouting port 603 is arra...

Embodiment 2

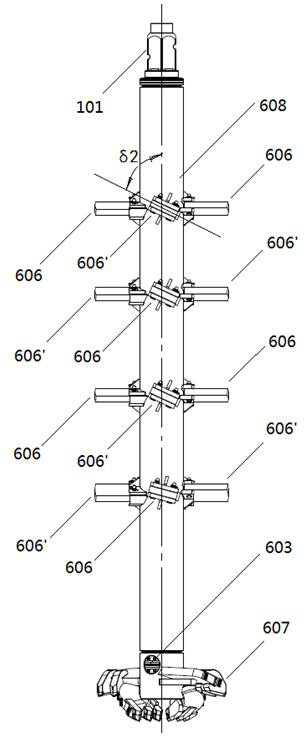

[0043]Different from Embodiment 1, when it is necessary to change the angle of the stirring blades of the drilling tool, multiple sets of first stirring blades 606 on the outer wall of the drilling tool body 608 can be disassembled, and multiple sets of second stirring blades 606' can be reinstalled . The multiple sets of second stirring blades 606' intersect at intervals up and down, and are symmetrically arranged on the outer wall of the drilling tool body 608 in such a way that the multiple sets of first stirring blades 606 are staggered at an included angle of 90° in the horizontal section direction. The stirring blades 606' all include second blades 6061' and second blade holders 6062'; the first blades 6061' of each set of second stirring blades 606' are mounted on the second blade holders 6062' through pin shafts; The second blade seat 6062 ′ is obliquely arranged on the outer wall of the drilling tool body 608 , and the angle δ2 between it and the axial centerline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com