A kind of paint coating method that can replace wall decoration layer

A decorative layer and coating technology, applied in covering/lining, construction, building construction, etc., can solve the problems of high cost of wallpaper decoration, non-environmental protection of wallpaper glue, short service life, etc., and achieve realistic decoration effect and excellent texture , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for coating a paint that can replace a wall decoration layer, comprising the steps of:

[0030] Step 1: Apply anti-cracking mortar on the base wall of the wall for large-scale leveling of the wall, apply alkali-resistant sealing primer after scraping rough putty, and then apply solid color primer;

[0031] Step 2: Evenly smear the fine texture paint to form a fine texture paint layer, the thickness of the fine texture paint layer is controlled at 1-1.5mm, and the fine texture paint is selected from quartz sand sticky matter in this embodiment;

[0032] Step 3: Maintain the fine-textured paint layer for 2-2.5 hours under standard conditions, and then use a paint knife to make several parallel-arranged directional grooves 1 on the fine-textured paint layer. The width of the scribed groove 1 is 2cm, and the depth is 0.5mm, fine texture paint is selected yellow for use in the present embodiment;

[0033] Step 4: Use an iron trowel to move along the line of the fin...

Embodiment 2

[0037] The difference from Example 1 is that in this example, the coating equipment is used to coat the fine-textured paint, and during the coating process, grooves 1 and corrugated ravines are made.

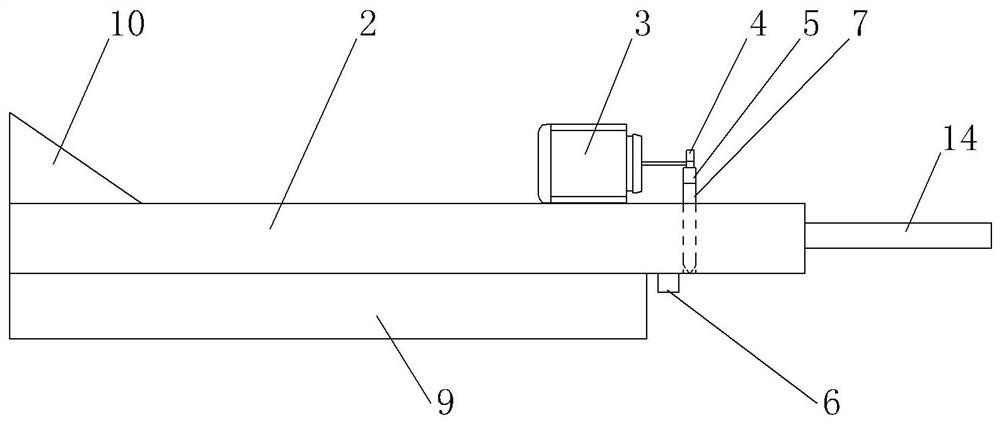

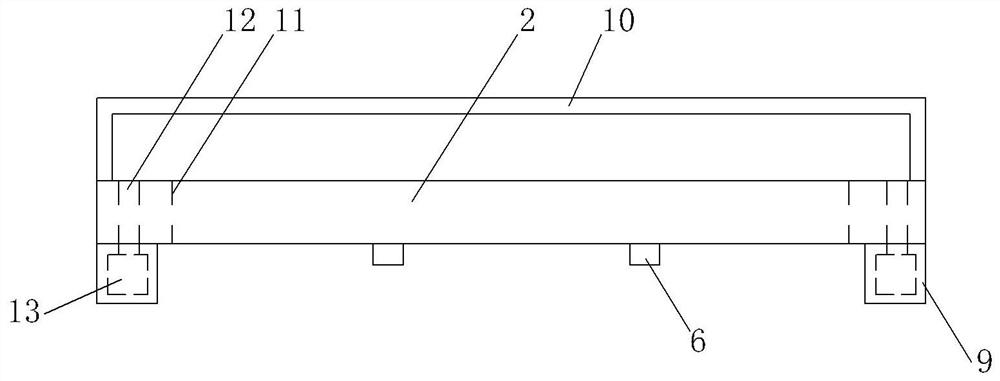

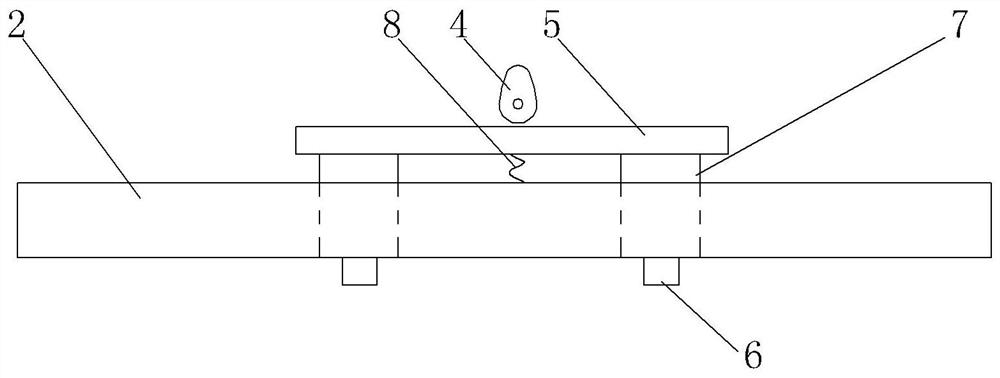

[0038] Specifically, in step 2, coating equipment is used to coat the fine texture paint, such as Figure 1-3 As shown, the coating equipment includes a coating plate 2 and a groove-making embossing mechanism, and a grip bar 14 is welded on the coating plate 2; the groove-making embossing mechanism includes a motor 3, a cam 4, a connecting bar 5 and two groove-making Embossing unit, each groove-making embossing unit includes groove-making bar 6 and embossing knife 7, and groove-making bar 6 is welded with coating plate 2; Through slot, the embossing knife 7 is slidably set in the through slot; the motor 3 is fixedly connected with the coating plate 2 through bolts, the cam 4 is welded with the output shaft of the motor 3, and the tip of the cam 4 can be connected with the connec...

Embodiment 3

[0041] On the basis of Example 2, such as Figure 1-3 As shown, a support block 9 is respectively welded on both sides of the lower end of the coated plate 2 , the support block 9 is flush with the side wall of the coated plate 2 , and the length of the support block 9 is less than the width of the coated plate 2 .

[0042]The upper end of the coating plate 2 is welded with a material holding tank 10, and the coating plate 2 is provided with a bar-shaped groove 11. The material holding tank 10 communicates with the lower end of the coating plate 2 through the bar-shaped groove 11. Texture paint; in addition, there is a material leakage groove 12 on the coating plate 2, and a material delivery groove 13 is opened in the support block 9, and the material leakage groove 12 is connected with the material delivery groove 13.

[0043] During the coating process, manually hold the grip rod 14 to drive the coating plate 2 to move, and the fine texture paint enters between the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com