High-speed air suspension compressor for fuel cell, fuel cell system and vehicle

An air suspension and fuel cell technology, applied in fuel cells, liquid fuel engines, electrical components, etc., can solve problems such as poor cooling effect, low speed, and large compressor volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

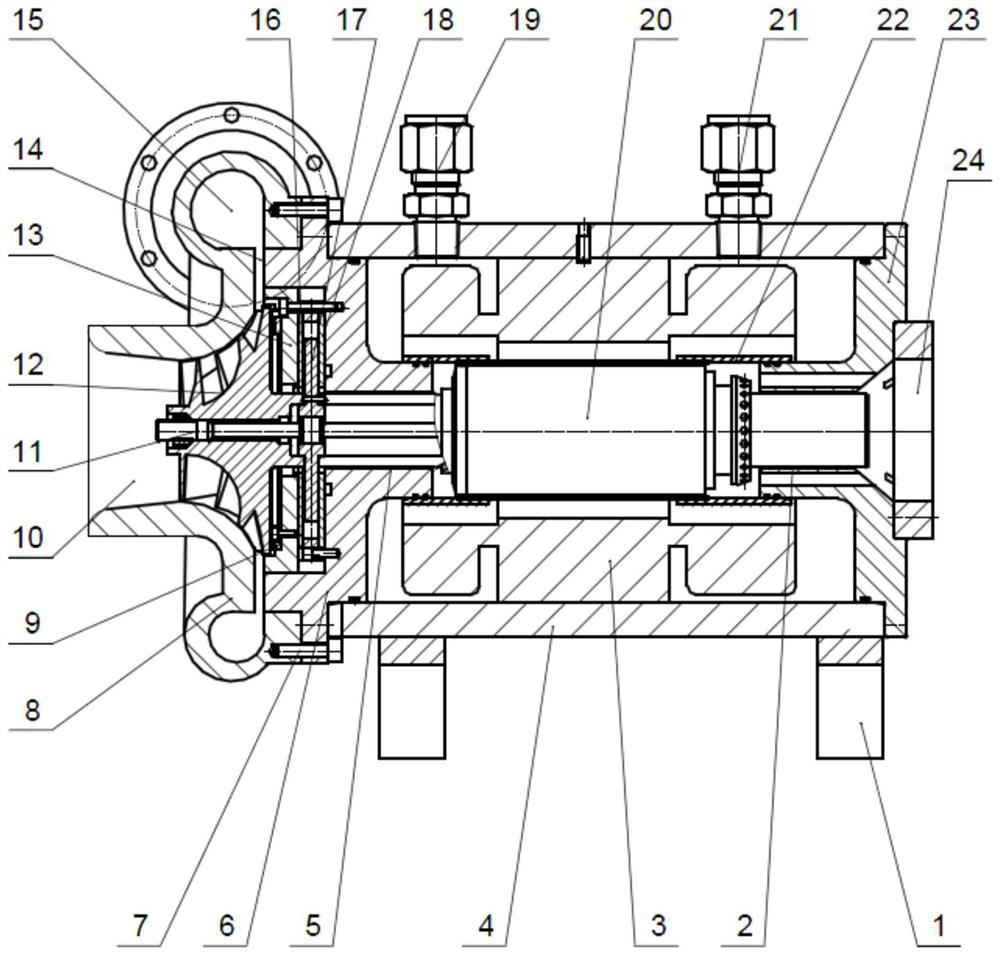

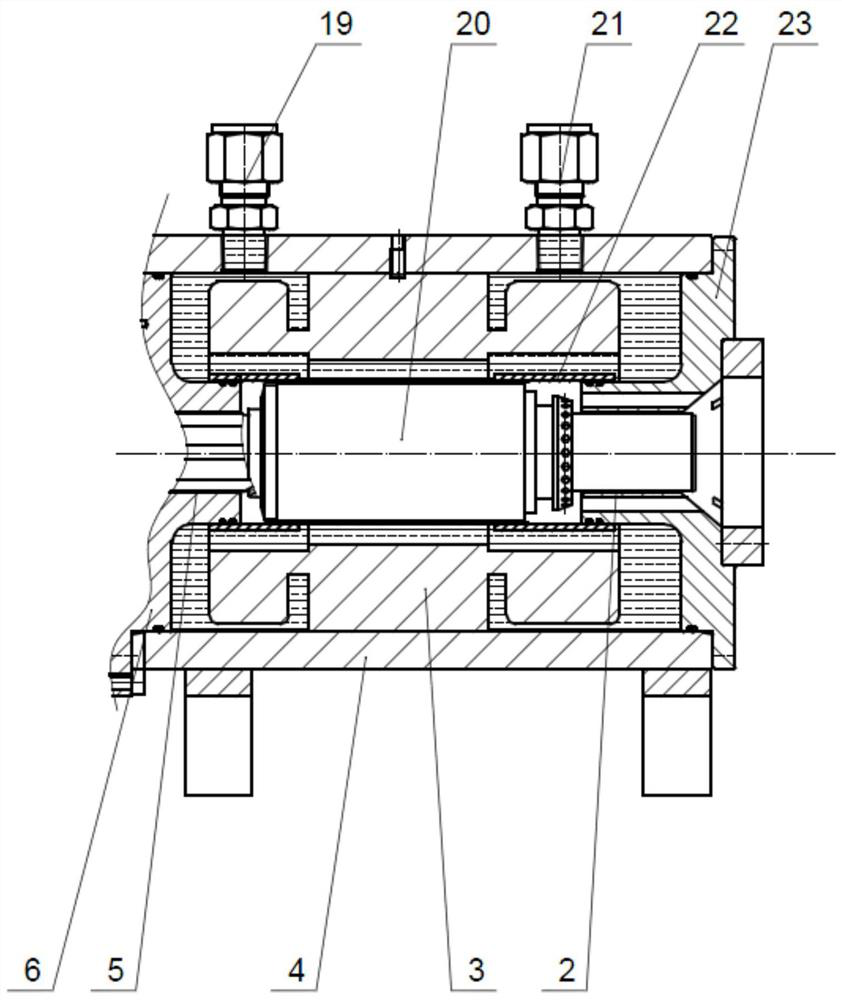

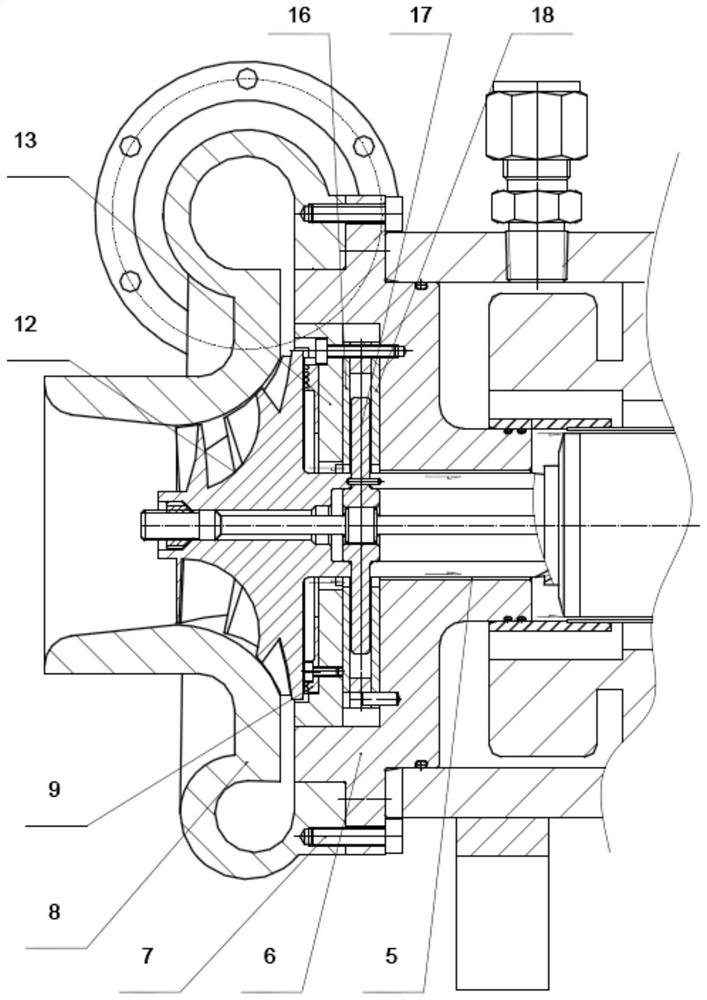

[0068] Embodiment 1: see figure 1 , 2 , 3, 4, 6, 10, a kind of fuel cell high-speed air suspension compressor of the present embodiment comprises:

[0069] Support 1, rear radial bearing 2, stator 3, housing 4, front radial bearing 5, front bearing housing 6, volute 8, labyrinth seal 9, stretching screw 11, impeller 12, thrust bearing housing 13, expansion Compressor 14, outer thrust bearing 16, thrust disc 17, inner thrust bearing 18, main shaft 20, rear bearing seat 23, rear cover 24 and partition sleeve, the partition sleeve is a three-stage split structure, including the front sleeve 26 , middle sleeve 25 and rear sleeve 22;

[0070] The shell 4 is arranged on the support 1, and the shell 4 is provided with a liquid inlet 19 and a liquid discharge port 21, and the liquid inlet 19 and the liquid discharge port 21 are connected with pipe joints;

[0071] The front bearing seat 6 is fixedly installed on the front end of the housing 4 by bolts, and the sealing ring is reali...

Embodiment 2

[0074] Embodiment 2: The difference from Embodiment 1 lies in the sealing method between the partition sleeve and the front bearing seat 6 and the rear bearing seat 23; specifically: there are sealing grooves on the outer walls of the front sleeve 26 and the rear sleeve 22, and the sealing Sealing ring is set in the groove, between the outer wall of front sleeve 26 and the inwall of front bearing block 6, install by sealing ring, between the outer wall of rear sleeve 22 and the inwall of rear bearing block 23, install by sealing ring. For details, see Figure 5 .

Embodiment 3

[0075] Embodiment 3: The difference from Embodiment 1 or Embodiment 2 is that the partition sleeve adopts an integrated manufacturing structure, and the two ends of the partition sleeve are sealed and installed with the front bearing seat 6 and the rear bearing seat 23 . For details, see Figure 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com