Wood drying device and using method thereof

A drying device and wood technology, applied in the direction of wood drying, drying, drying machine, etc., can solve the problems of high energy consumption, affecting the quality of round logs, and easy bending of round logs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

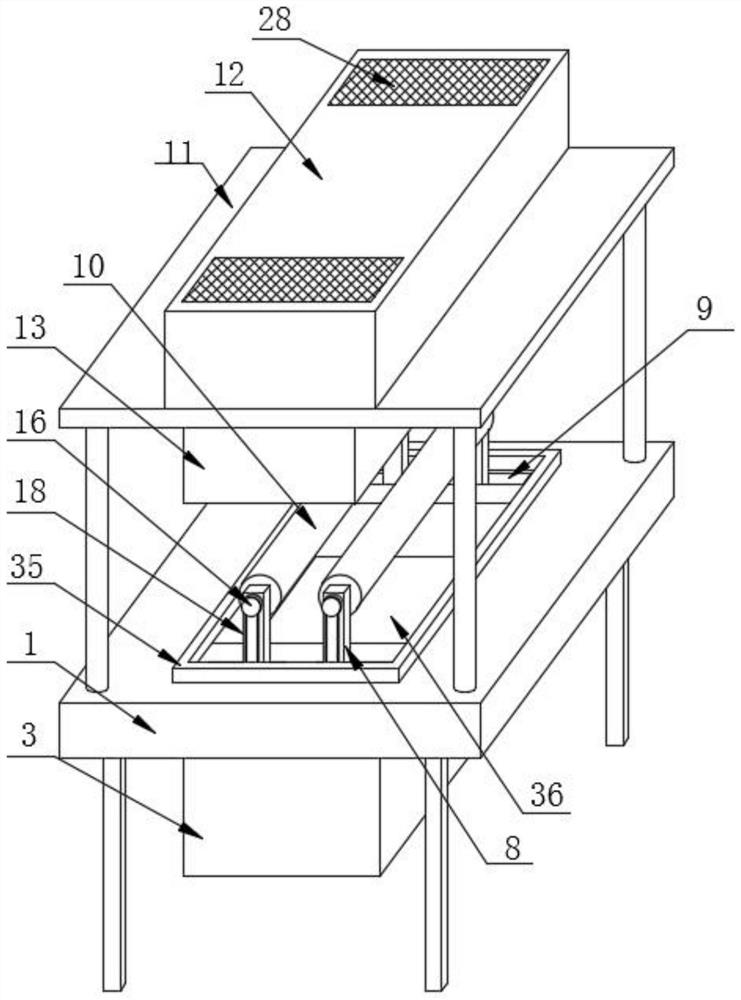

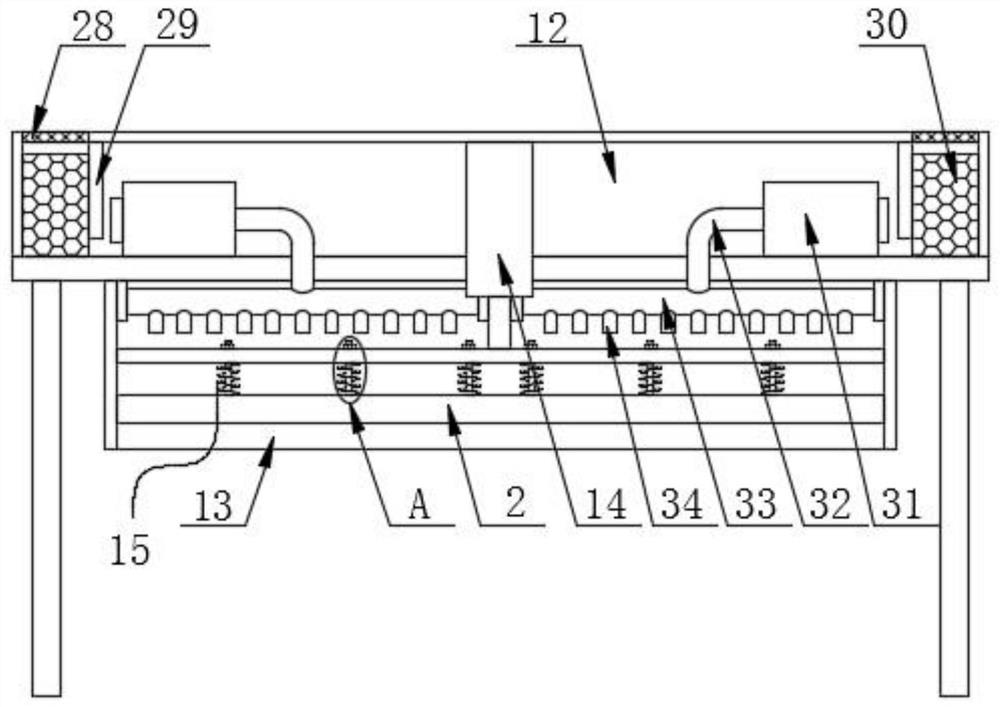

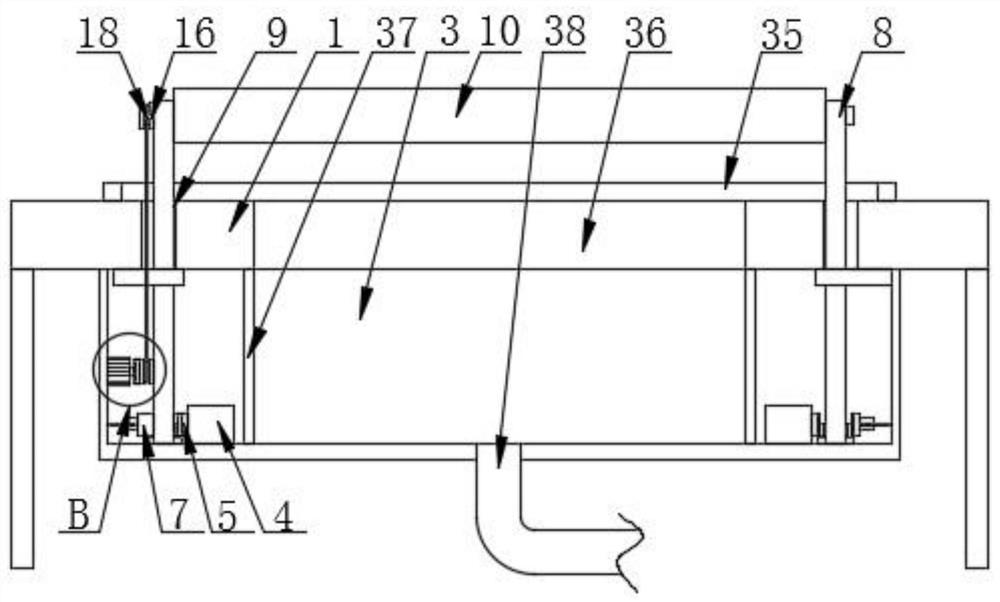

[0035] A wood drying device includes a work frame 1 and a drying board 2 arranged above the work frame 1 .

[0036]As a preferred solution, a water storage tank 3 is fixedly connected to the bottom of the top plate of the working frame 1, and a cylinder 4 is fixedly connected to the front and rear sides of the bottom of the inner cavity of the water storage tank 3. The cylinder 4 is electrically connected to the external power supply and is controlled by a control switch. The surface of the push rod of the cylinder 4 is fixedly connected with the first tooth plate 5 through the connecting plate, and the bottom of the inner cavity of the water storage tank 3 is located between the first tooth plate 5 and the opposite side of the inner wall of the water storage tank 3 through the bearing to rotate A gear 6 matched with the first tooth plate 5 is connected, the front and rear sides of the inner cavity of the water storage tank 3 are slidably installed with a second tooth plate 7 m...

Embodiment 2

[0038] This embodiment is an improvement of the previous embodiment,

[0039] A wood drying device includes a work frame 1 and a drying board 2 arranged above the work frame 1 .

[0040] As a preferred solution, a water storage tank 3 is fixedly connected to the bottom of the top plate of the working frame 1, and a cylinder 4 is fixedly connected to the front and rear sides of the bottom of the inner cavity of the water storage tank 3. The cylinder 4 is electrically connected to the external power supply and is controlled by a control switch. The surface of the push rod of the cylinder 4 is fixedly connected with the first tooth plate 5 through the connecting plate, and the bottom of the inner cavity of the water storage tank 3 is located between the first tooth plate 5 and the opposite side of the inner wall of the water storage tank 3 through the bearing to rotate A gear 6 matched with the first tooth plate 5 is connected, the front and rear sides of the inner cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com