Fabricated acoustic metamaterial and acoustic baffle

An assembled and superstructure technology, applied in the field of acoustic metamaterials, can solve problems such as performance degradation, low-frequency sound insulation performance degradation, and reduced frequency band sound insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

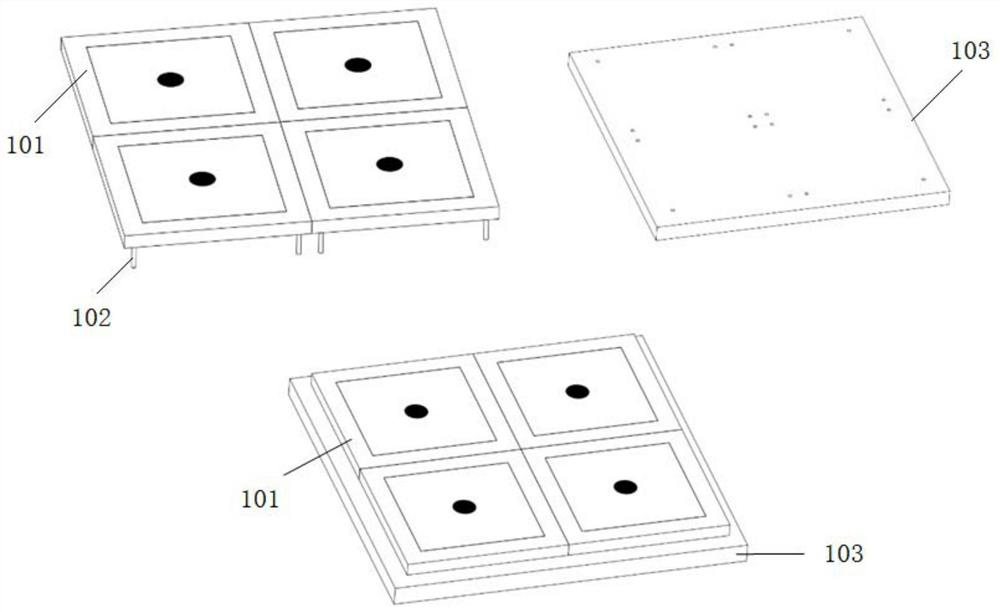

[0050]Such asfigure 1 As shown, the support structure of the present embodiment is a support plate 103, and the acoustic supercons constructed by a plurality of assembling acoustic supercons 101 and the support plate 103. The assembly of the assembly acoustic superomer is the fine needle 102 of the bottom surface. Each assembled acoustic supercuter is 1 quadrilateral membrane type acoustic super material unit, and the acoustic supercons constructed from four mating acoustic supercons and support plates.

Embodiment 2

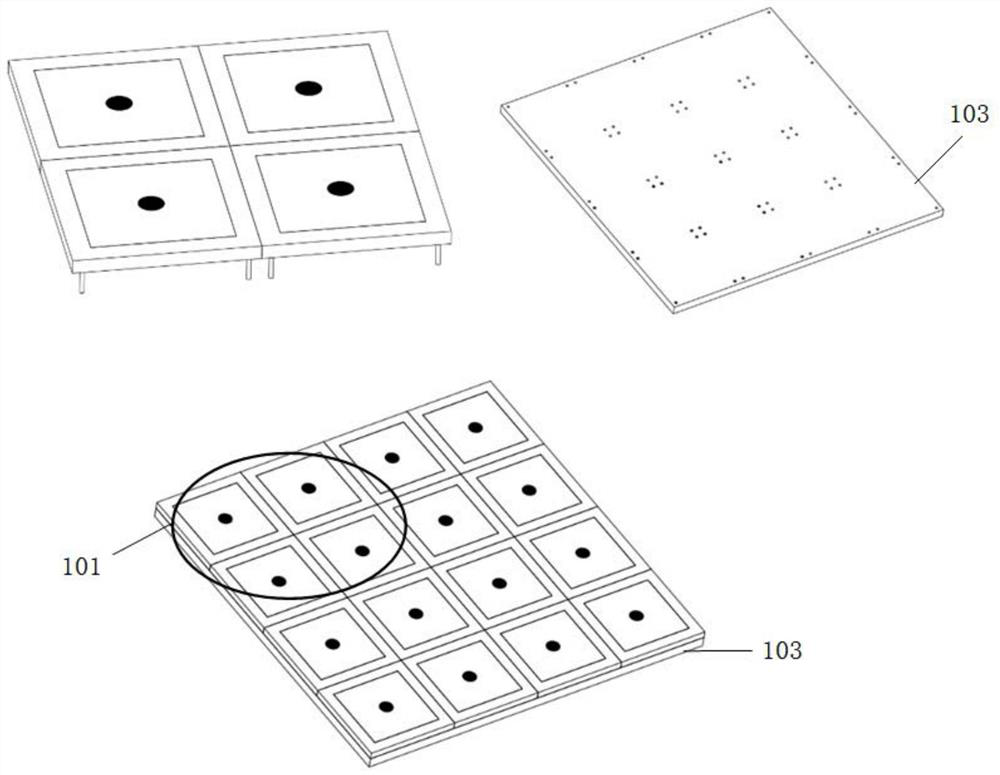

[0052]Such asfigure 2 As shown, the first embodiment is different from that of the first embodiment, each of the assembled acoustic supercodes 101 of the present embodiment comprise four four-sided film type acoustic ultravailable material units that are directly fixed as an integral.

Embodiment 3

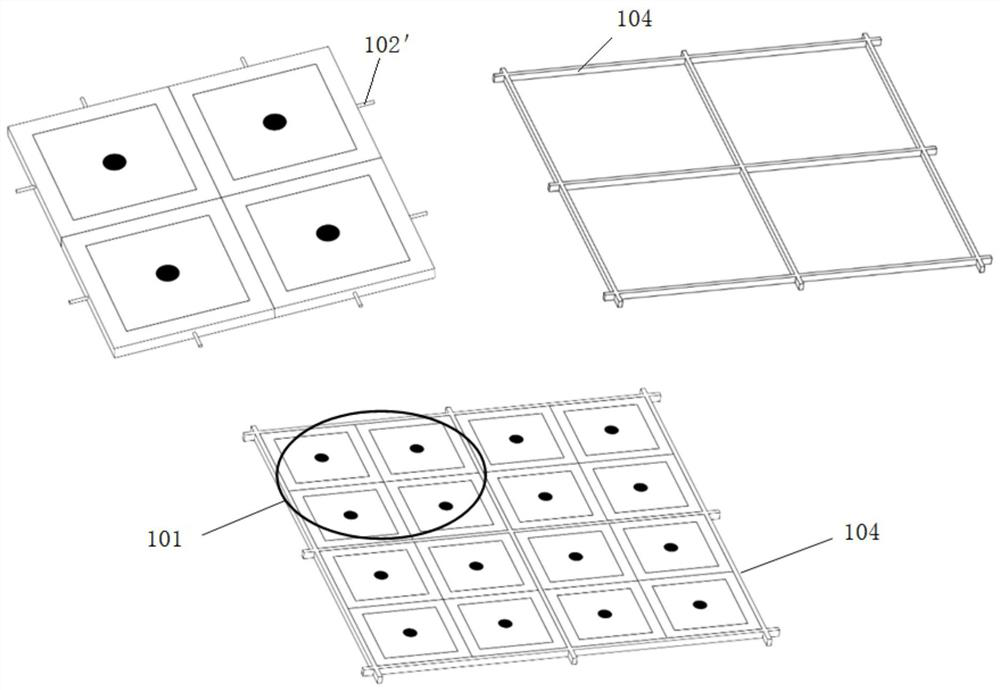

[0054]Such asimage 3 As shown, the support structure of the present embodiment is a support frame 104, and the acoustic supercons constructed by a plurality of assemblies acoustic supercons 101 and the support frame 104. The assembly of the assembly acoustic superomer is a side of the fine needle 102 '. Each assembled acoustic supercomputer 101 can contain four quadrangular membrane type acoustic super material units, and the acoustic supercomposed layer can be constructed from four mating acoustic supercons and support frames.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com