A workpiece grabbing method, device, computer equipment and storage medium

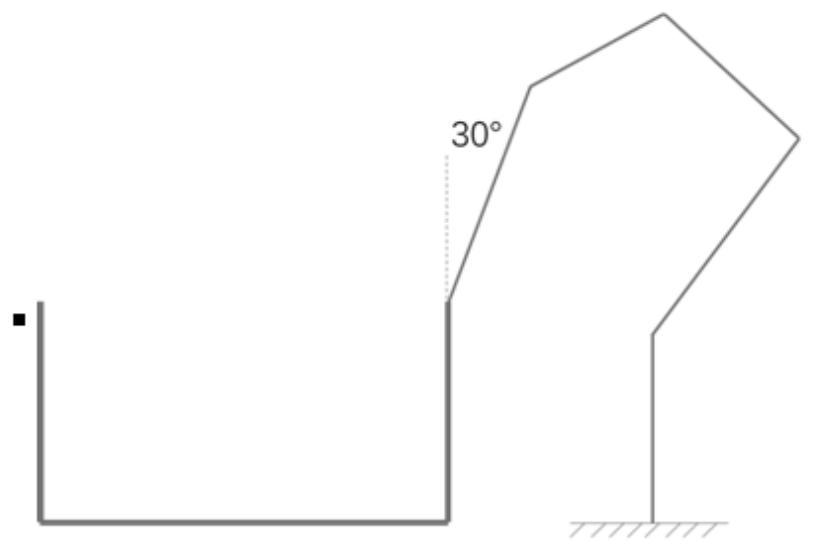

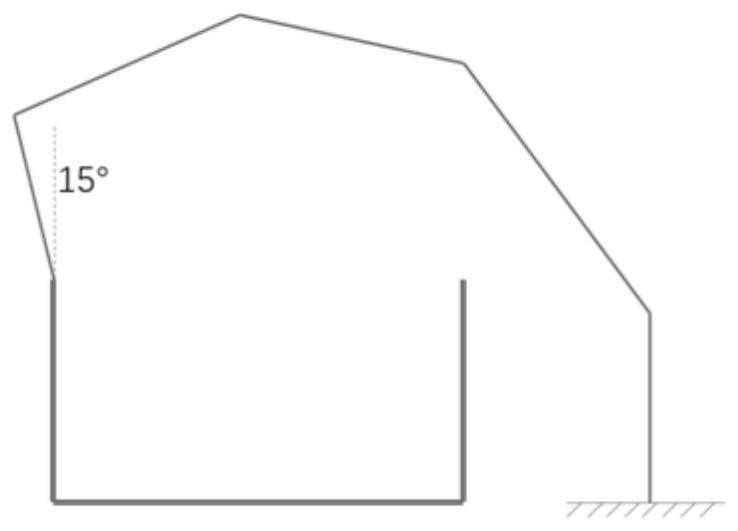

A workpiece and component technology, which is applied in the fields of workpiece grasping, devices, computer equipment and storage media, can solve the problems of only reaching 15°, overlap of workpieces, and insufficient robot arm span, so as to save arm span, avoid strange posture, The effect of improving the success rate of crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

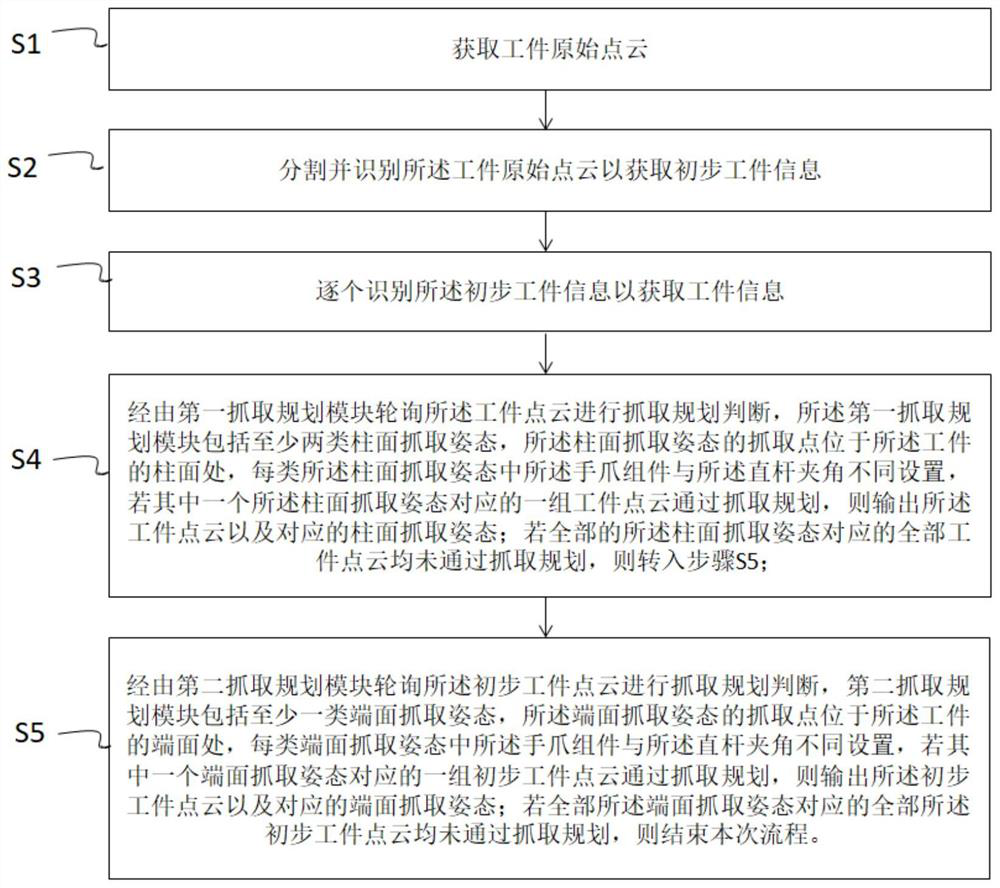

[0151] The present invention also discloses a workpiece grabbing device 10, which uses an end gripper to grip a workpiece, and the end gripper includes a straight rod and a gripper assembly connected to the straight rod; the gripper assembly is connected to the straight rod The straight bar is arranged at an included angle and the included angle is adjustable, the straight bar is used to connect the external mechanical arm so that the mechanical arm is located outside the material frame, and the gripper assembly is arranged vertically to the workpiece to be grasped;

[0152] Such as Figure 23 As shown, the workpiece grabbing device 10 includes:

[0153] The original point cloud acquisition module 11 of the workpiece is used to obtain the original point cloud of the workpiece;

[0154] Preliminary workpiece information acquisition module 12, used to segment and identify the original point cloud of the workpiece to obtain preliminary workpiece information, and transfer to the ...

Embodiment 4

[0179] Figure 24 Shown is a schematic structural diagram of a computer device provided by an embodiment of the present invention, such as a smart phone, a tablet computer, a notebook computer, a desktop computer, a rack server, a blade server, a tower server or a cabinet server that can execute programs (including independent servers, or server clusters composed of multiple servers), etc. The computer device 20 of this embodiment at least includes but is not limited to: a memory 21 and a processor 22 that can communicate with each other through a system bus, such as Figure 24 shown. It should be pointed out that, Figure 24 Only computer device 20 is shown having components 21-22, but it should be understood that implementing all of the illustrated components is not a requirement and that more or fewer components may instead be implemented.

[0180] In this embodiment, the memory 21 (that is, a readable storage medium) includes a flash memory, a hard disk, a multimedia ca...

Embodiment 5

[0183] The present application also provides a computer-readable storage medium, such as flash memory, hard disk, multimedia card, card-type memory (for example, SD or DX memory, etc.), random access memory (RAM), static random access memory (SRAM), read-only Memory (ROM), Electrically Erasable Programmable Read-Only Memory (EEPROM), Programmable Read-Only Memory (PROM), Magnetic Storage, Magnetic Disk, Optical Disk, Server, App Store, etc., on which computer programs, program When executed by the processor, corresponding functions are realized. The computer-readable storage medium in this embodiment is used to store the program code of the workpiece grasping device, and when executed by the processor, implements the workpiece grasping method in the method embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com