Equipment and method for breaking partial tunnel lining by microwaves

A technology for tunnels and equipment, applied in tunnel lining, separation methods, tunnels, etc., can solve the problems of single tunnel lining removal method, difficulty in hiring construction workers, tunnel collapse, etc., achieving simple and convenient equipment operation, saving crushing costs, saving effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

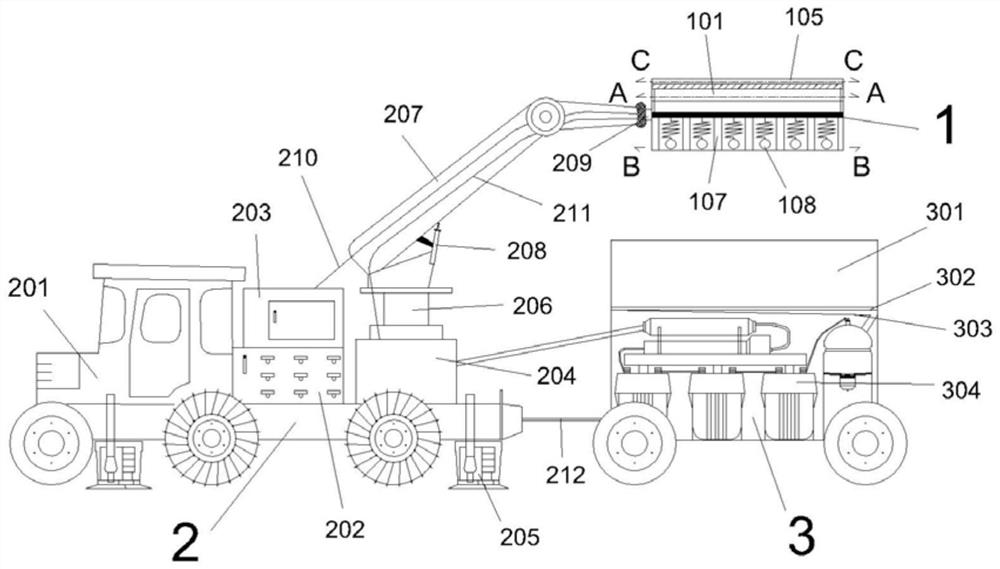

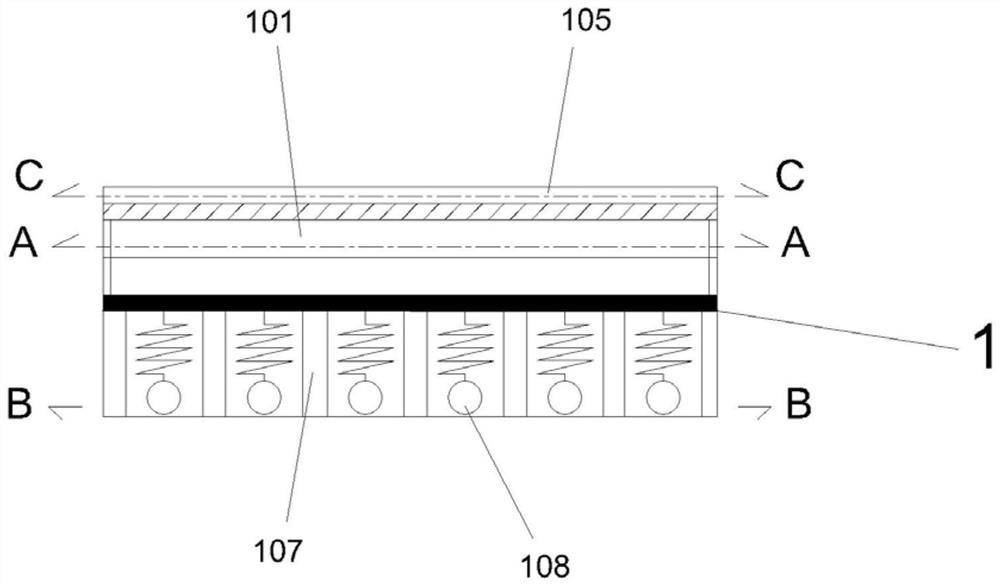

[0036] Such as figure 1 As shown, a microwave crushing equipment for partial tunnel lining of the present invention includes a crushing device 1 , a locomotive power device 2 and a recovery device 3 . The crushing device 1 is connected to the locomotive power device 2 through the mechanical arm 207, and the recovery device 3 is connected to the tail of the locomotive power device 2 and below the crushing device 1;

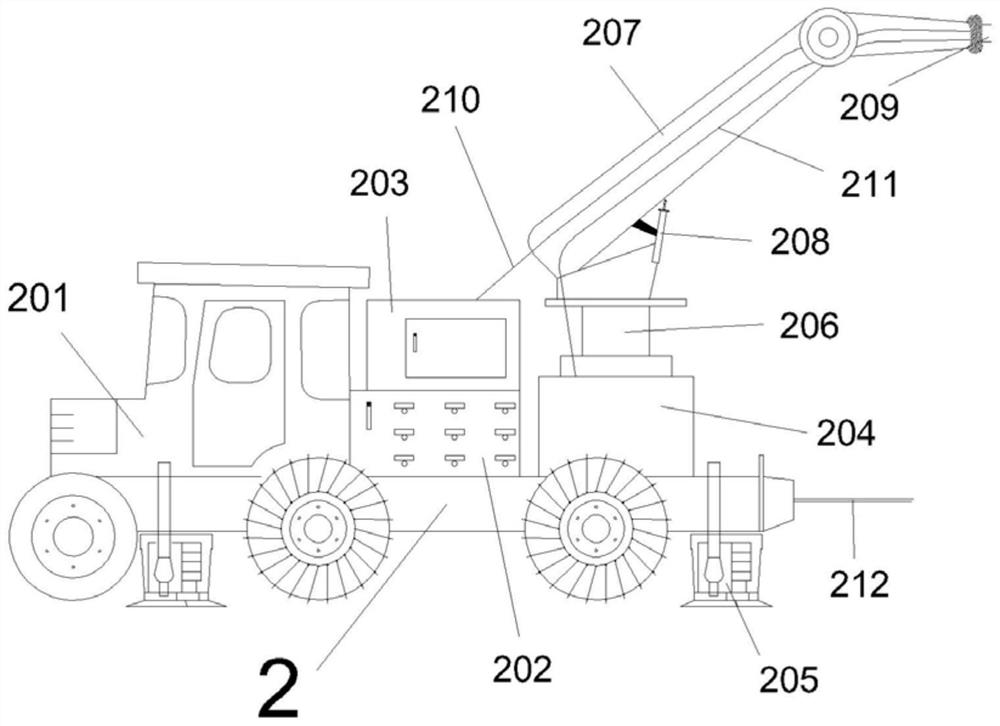

[0037] Such as figure 2 As shown, the locomotive power unit 2 includes a driving system 201, a PLC control room 202, a power supply device 203, a water supply device 204, a hydraulic jack 205, a base 206, a mechanical arm 207, a mechanical arm cylinder 208, a bearing 209, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com