Colorless transparent polyimide film, preparation method thereof and LED film screen

A transparent polyimide and polyimide resin technology, applied in the film field, can solve the problems of low transmittance and elastic modulus, poor dimensional stability, and poor heat dissipation of film materials, and achieve high elastic modulus and transparent Good effect of service life and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

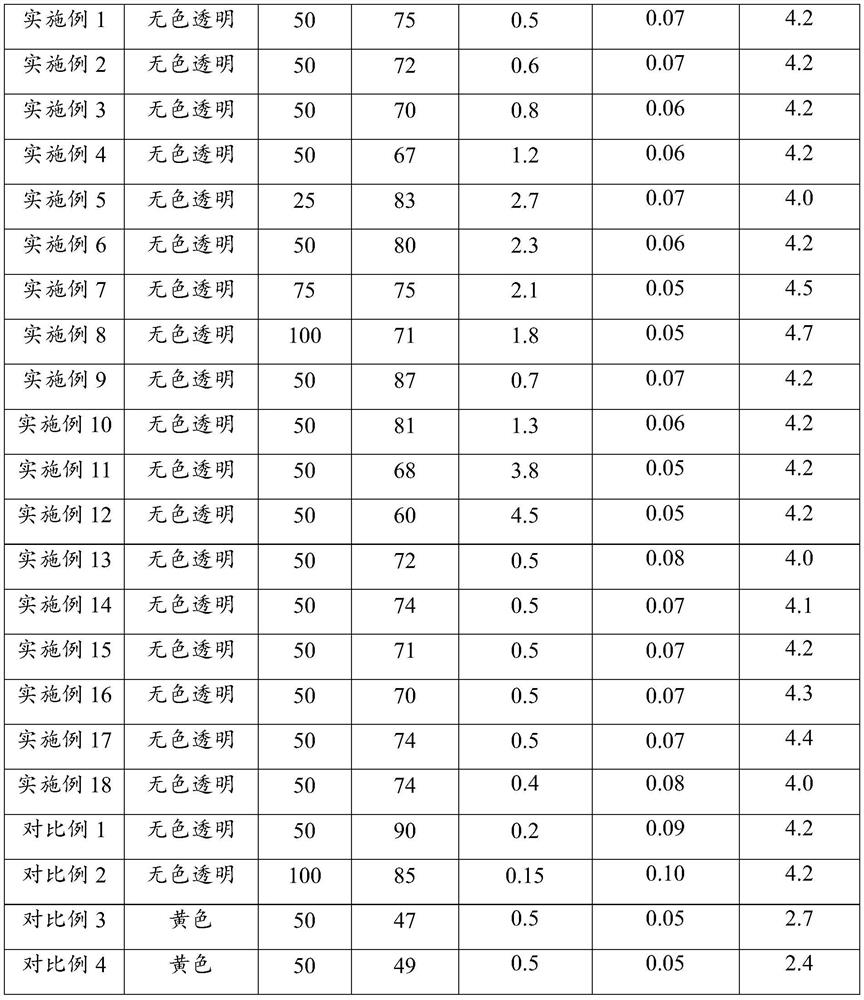

Examples

Embodiment approach

[0065] As an optional embodiment of the present invention, the dianhydride includes 50-100 mol% dianhydride A and 0-50 mol% dianhydride B.

[0066] Among them, dianhydride A includes 4,4'-hexafluoroisopropyl phthalic anhydride, 1,2,4,5-cyclohexane tetracarboxylic dianhydride, 1,2,3,4-cyclobutane tetra Any one or a combination of at least two of formic dianhydride or 1,2,3,4-cyclopentadicarboxylic dianhydride;

[0067] Dianhydride B includes pyromellitic dianhydride, 3,3',4,4'-biphenyltetracarboxylic dianhydride, 2,3,3',4-biphenyltetracarboxylic dianhydride, 3,3' ,4,4'-Benzophenone tetracarboxylic dianhydride, 4,4'-oxodiphthalic anhydride, 1,2,4,5-cyclohexanetetracarboxylic dianhydride, 1,2, Any one or a combination of at least two of 3,4-cyclobutanetetracarboxylic dianhydride, 1,2,3,4-cyclopentadicarboxylic dianhydride, bisphenol A dianhydride or bisphenol F dianhydride .

[0068] Typical but non-limiting amounts of dianhydride A are 50 mol%, 55 mol%, 60 mol%, 65 mol%, 70 m...

Embodiment 1

[0116] This embodiment provides a kind of colorless and transparent polyimide film, mainly adopts following raw material to make: polyimide resin and heat-conducting filler; Wherein, polyimide resin is mainly made of dianhydride A(1,2,3 , 4-cyclobutanetetracarboxylic dianhydride) and diamine A (2,2'-bis(trifluoromethyl)diaminobiphenyl) are obtained by polycondensation under the action of a dehydrating agent (acetic anhydride) and a catalyst (pyridine); The thermally conductive filler is a modified inorganic thermally conductive filler, that is, α-alumina modified by γ-aminopropyltriethoxysilane, and the mass of the thermally conductive filler accounts for 60% of the total mass of the colorless and transparent polyimide film.

[0117] The preparation method of the above-mentioned colorless transparent polyimide film provided in this embodiment comprises the following steps:

[0118] (a) Provide thermally conductive paste formed by thermally conductive fillers and organic polar ...

Embodiment 2

[0128]This embodiment provides a colorless and transparent polyimide film, except that the average particle size of the thermally conductive filler is changed from 0.05 μm to 0.5 μm, and the rest of the raw materials, dosage and preparation method are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com