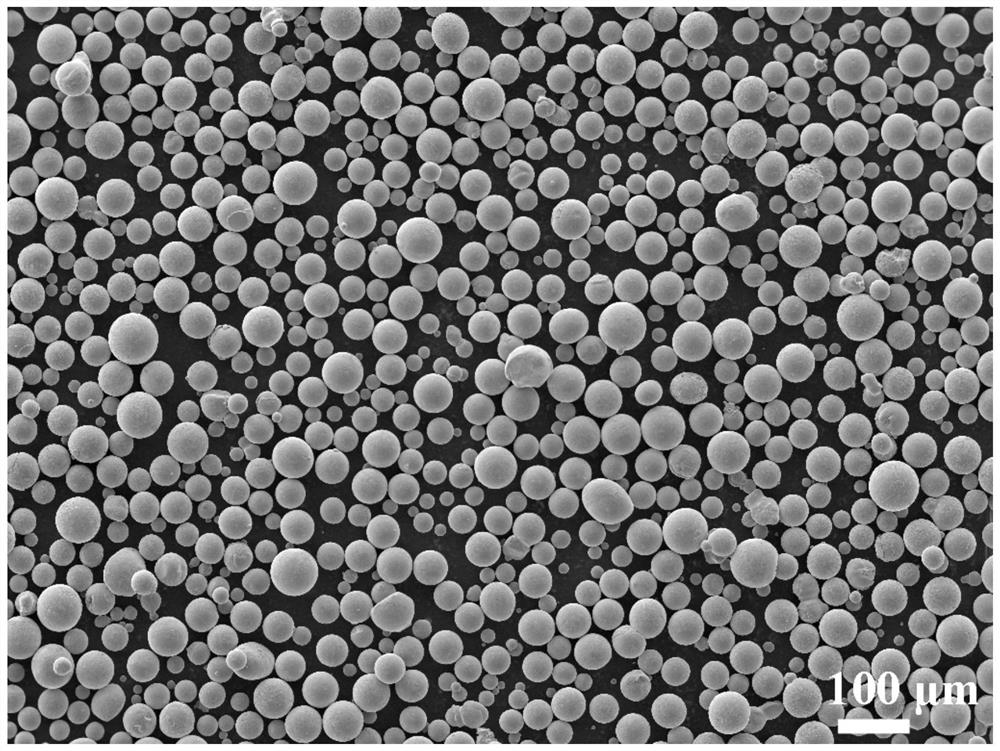

Rare earth aluminum alloy powder suitable for additive manufacturing and preparation method of rare earth aluminum alloy powder

A technology of additive manufacturing and alloy powder, which is applied in the field of additive manufacturing, can solve the problems of small application range, single function, and less selection of types, and achieve the effects of no environmental pollution, simple process, and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a rare earth aluminum alloy powder suitable for additive manufacturing, which is composed of the following elements in weight percentage: 10.00% Ce, 0.60% Mg, 0.10% Y, 0.25% Zr, and other impurities Less than 0.1%, the rest is aluminum.

[0033] The above-mentioned rare earth aluminum alloy powder suitable for additive manufacturing can be prepared by the following preparation methods, including:

[0034] S1, under the protection of high-purity argon, the aluminum ingot is heated and melted in an induction furnace at a temperature of 750°C.

[0035] S2, add the required alloying elements to the above aluminum liquid, adjust the ratio of each element by using the intermediate alloy, degas and remove the slag, and make its composition reach 10.00% of Ce, 0.60% of Mg, 0.10% of Y, 0.25% of Zr, The rest is aluminum, and the composition error is less than 0.02%, forming alloy liquid.

[0036] S3, lead the above-mentioned alloy liquid from the bottom...

Embodiment 2

[0040] This embodiment provides a rare earth aluminum alloy powder suitable for additive manufacturing, which is composed of the following elements in weight percentage: 8.00% Ce, 0.40% Mg, 0.10% Y, 2.50% Zr, and other impurities Less than 0.1%, the rest is aluminum.

[0041] The above-mentioned rare earth aluminum alloy powder suitable for additive manufacturing can be prepared by the following preparation methods, including:

[0042] S1, under the protection of high-purity argon, the aluminum ingot is heated and melted in an induction furnace to form aluminum liquid at a temperature of 730°C.

[0043] S2, add the required alloying elements to the above-mentioned aluminum liquid, adjust the ratio of each element with the intermediate alloy, degas and remove the slag, and make its composition reach 8.00% of Ce, 0.40% of Mg, 0.10% of Y, 2.50% of Zr, The rest is aluminum, and the composition error is less than 0.02%, forming alloy liquid.

[0044] S3, lead the above-mentioned ...

Embodiment 3

[0048] This embodiment provides a rare earth aluminum alloy powder suitable for additive manufacturing, which is composed of the following elements in weight percentage: 10.00% Ce, 0.60% Mg, 0.10% Y, 0.20% Zr, and other impurities Less than 0.1%, the rest is aluminum.

[0049] The above-mentioned rare earth aluminum alloy powder suitable for additive manufacturing can be prepared by the following preparation methods, including:

[0050] S1, under the protection of high-purity nitrogen, the aluminum ingot is heated and melted in an induction furnace to form aluminum liquid at a temperature of 780°C.

[0051] S2, add the required alloying elements to the above-mentioned aluminum liquid, adjust the ratio of each element by using the intermediate alloy, degas and remove the slag, and make its composition reach 10.00% of Ce, 0.60% of Mg, 0.10% of Y, 0.20% of Zr, The rest is aluminum, and the composition error is less than 0.02%, forming alloy liquid.

[0052] S3, lead the above-m...

PUM

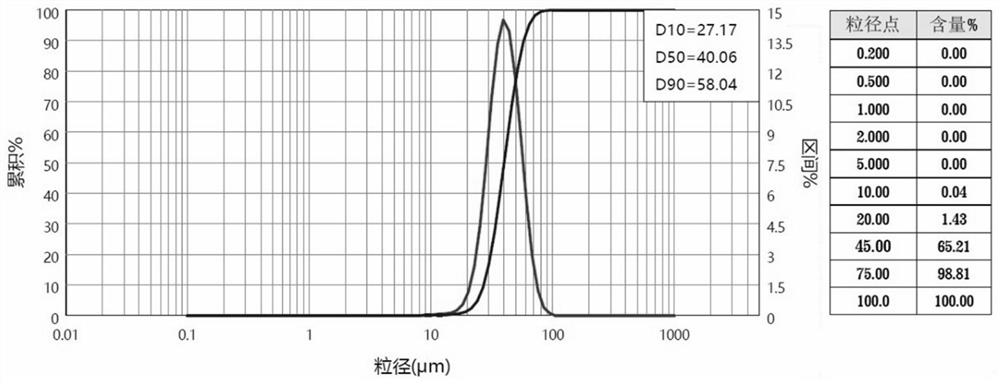

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com