Method for improving ink jet stability and pyrograph color effect by changing hot melt adhesive powder

A hot-melt adhesive powder and color effect technology, applied in dyeing, transfer printing, printing, etc., can solve problems such as clogged inkjet head, difficult to white ink, unstable white ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

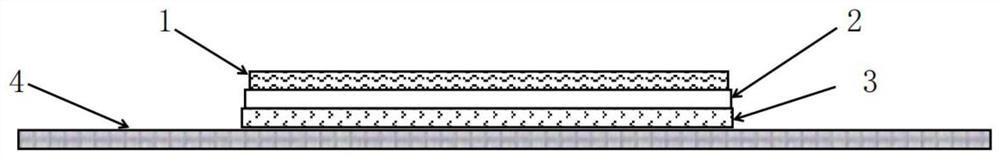

Image

Examples

preparation example Construction

[0033] The present invention provides two preparation methods for the preparation of auxiliary color hot-melt adhesive powder, which are respectively a hot-melt preparation method and a mixing preparation method, and the specific steps are as follows:

[0034] Hot-melt preparation method: add auxiliary toner (titanium dioxide, pearl powder or metallic toner) to hot-melt adhesive powder (TPU is the best choice) and stir evenly, heat up and melt and granulate to obtain corresponding hot-melt adhesive particles ( white, pearlescent or metallic color), and then pulverize the hot melt adhesive particles in a refrigerated pulverizer to obtain 60-200 mesh auxiliary color hot melt adhesive powder (white hot melt adhesive powder, pearlescent hot melt adhesive powder or metallic color hot melt powder).

[0035] Mixing preparation method: put auxiliary color powder (titanium dioxide, pearl powder or metallic toner) and hot melt adhesive powder in a powder mixer and fully mix and stir to ...

Embodiment

[0045] 1. The composition and weight percentage of light white paint ink are shown in the following table:

[0046] ingredient name Product name Specification or ratio weight percentage white pigment dispersion white dispersion NK-WNE05 15% Water-based hot melt adhesive resin Self-dispersing waterborne polyurethane W6110 5% water-based resin Vinyl resin VINYBLAN 5% moisturizer Ethylene glycol and glycerol 3:1 20% Surfactant Suryfnol 465: BYK 2:1 1.5% fungicide Azoline fungicides BIT 0.5% Deionized water 43%

[0047] The preparation method of light white paint ink comprises the following steps:

[0048] Step 1. First add deionized water and moisturizing agent into the dispersion tank and stir evenly to obtain the first mixed solution;

[0049] Step 2, adding the surfactant and the bactericide into the first mixed solution and stirring evenly to obtain the second mixed solution;

[0050] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com