Data acquisition method based on industrial internet operating system

An industrial Internet and operating system technology, applied in the field of data collection based on the industrial Internet operating system, can solve the problems of wasting the efficiency of skilled workers, increasing the rate of defective products, and reducing the production efficiency of the assembly line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, those of ordinary skill in the art have not made an inventive step

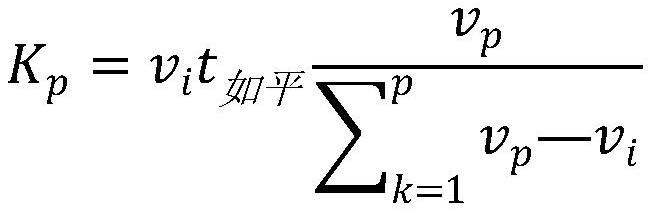

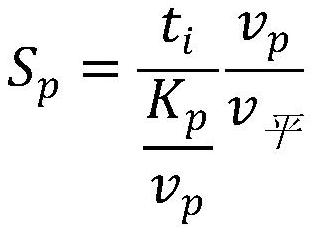

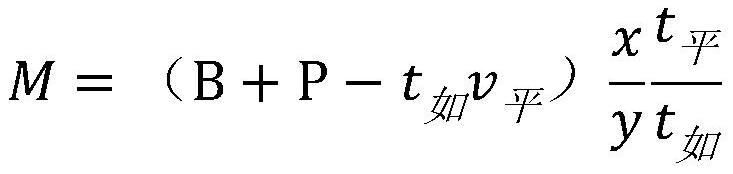

[0035] The invention provides a technical solution: a data acquisition method based on an industrial Internet operating system. The system used in the method includes a worker offline system and a production line fine-tuning system. The worker offline system includes an offline trigger unit, a toilet time statistics module, and a toilet type input Module, reward module, production line fine-tuning system includes workpiece storage unit, transmission speed adjustment unit, laser marking unit, workpiece processing and distribution module, acceleration range statistics module, laser marking unit and workpiece processing and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com