Exhaust-gas plasma detoxification method, and device for same

A plasma and waste gas technology, applied in the directions of plasma, separation method, gas treatment, etc., can solve the problems of not easy to decompose, difficult to remove PFC, and unable to place the greenhouse effect on the earth's environment, so as to achieve the improvement of the removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

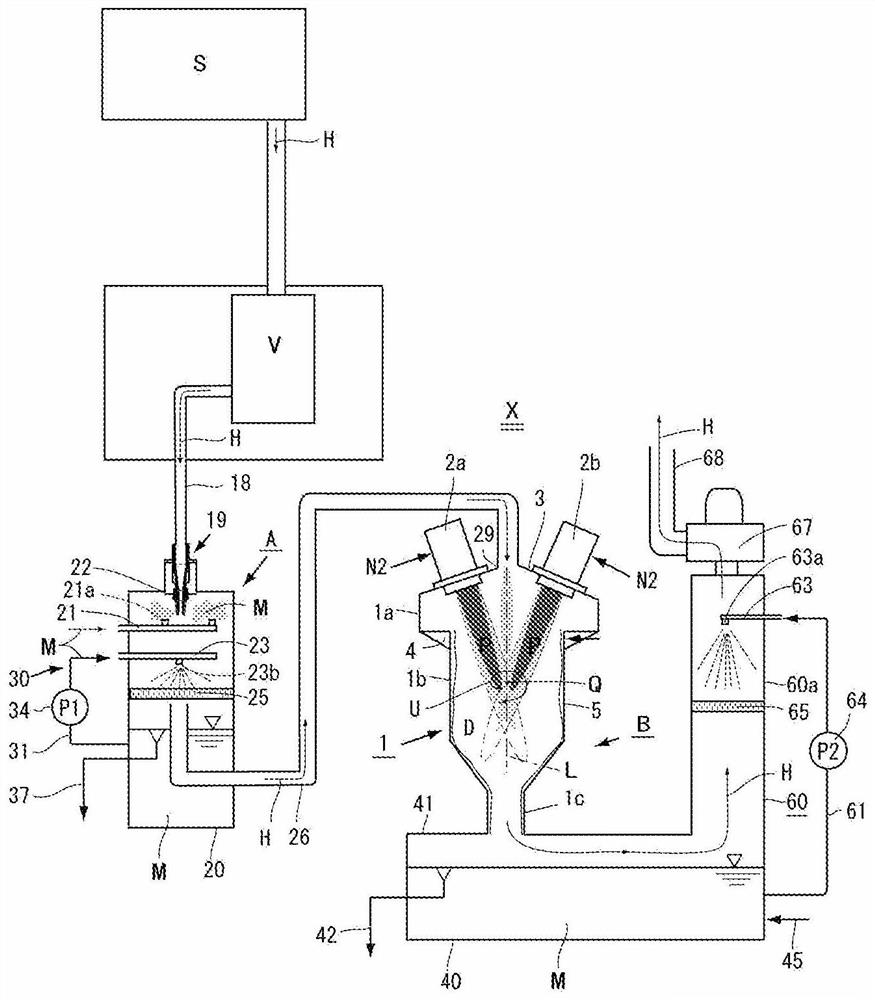

[0037] Hereinafter, the present invention will be described based on illustrated embodiments. figure 1 It is the exhaust gas treatment device X of the present invention. These are devices used in the semiconductor manufacturing process. For example, exhaust gas H exhausted from CVD film formation equipment S is sucked by vacuum pump V, transported to exhaust gas treatment equipment X, decomposed by thermal decomposition, and discharged to the atmosphere.

[0038] In addition, in the description of the background art, the detoxification of PFC exhaust gas was taken as a representative example for description, but since the refractory exhaust gas is not limited to PFC exhaust gas, the gas to be treated in the present invention is simply referred to as exhaust gas H.

[0039] figure 1In one example, the exhaust gas treatment device X is composed of an independent water treatment device A and a thermal decomposition device B provided with an outlet scrubber 60 . Although not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com